When you look for a forklift reach stacker that fits your logistics networks, you want the best mix of power, efficiency, and safety. Top models for 2025 include TONA-TEC RS Series, Kalmar Generation, Toyota Container Handler, Hyster RS46, Taylor Series, and XRS-9972. TONA-TEC stands out with high-visibility masts and smooth AC drive motors. If you need heavy lifting, consider models like the SRSC45H4, which offers inching control and a hydraulic load-sensing system.

Here’s a quick look at standout models:

Model | Max Load (lbs) | Key Feature |

|---|---|---|

RS-450 | 99,000 | High-visibility mast |

Kalmar Gen | 99,208 | Rugged, intelligent controls |

Toyota CH | 99,000 | AC drive, battery efficiency |

Hyster RS46 | 101,000 | Wide performance range |

Taylor Series | 99,000 | Adaptable attachments |

XRS-9972 | 99,000 | Electric, top energy savings |

Choose the right stacker for your load, space, and workflow.

Top Forklift Reach Stacker Models

TONA-TEC RS Series

The TONA-TEC RS Series stands out in the forklift reach stacker market. You get a blend of power, safety, and advanced technology. TONA-TEC designs its machines for tough environments and high-volume container handling solutions. The RS Series includes four main models: RS-450, RS-550, RS-350, and RS-600. Each model offers unique strengths for different warehouse and port needs.

RS-450

The RS-450 gives you a strong engine and advanced hydraulic systems. You can handle heavy loads with confidence. The RS-450 uses a Cummins QSM11 engine that delivers 246 kW at 2200 rpm. The ZF 5WG261 transmission provides smooth automatic shifting. The Kessler wide-type drive axle and Linde hydraulic pump ensure stability and precise control.

Feature | Specification |

|---|---|

Engine | Cummins QSM11, 246 kW @ 2200 rpm |

Transmission | ZF 5WG261, 5/3 gears auto-shift |

Drive Axle | Kessler D102PL341-NLB wide type |

Steer Axle | Kessler L102 |

Tyres | 18.00-25 PR40 |

Pump | Linde hydraulic |

Valve | Linde hydraulic |

Spreader Type | ISO 20'-40' containers |

Lifting Capacity | 5 high 9’6” or 6 high 8’6” containers |

Tip: The RS-450 features a high-level air prefilter for dust resistance and an automatic engine speed adjustment. This helps you save fuel and maintain performance.

RS-550

You can rely on the RS-550 for even heavier loads and higher stacking. This model builds on the RS-450’s strengths but adds more lifting power. The advanced design concept improves stability and safety. The RS-550 also uses automatic engine management, which adjusts speed based on joystick movement. This feature boosts efficiency and reduces fuel use.

Engine intake air prefilter keeps dust out.

Advanced stability design ensures safe operation.

Automatic speed adjustment saves fuel.

RS-350

The RS-350 is ideal if you need a compact yet powerful forklift reach stacker. It fits tight spaces but still handles standard containers. The RS-350 uses the same high-quality components as larger models. You get reliable performance and easy maintenance.

Compact size for narrow aisles.

Handles ISO 20’-40’ containers.

Maintains high safety standards.

RS-600

The RS-600 is your choice for the most demanding container handling solutions. It offers the highest lifting capacity in the RS Series. The RS-600 uses advanced hydraulic and electronic systems. You can stack containers higher and faster. The wide drive axle and robust frame give you extra stability.

Maximum lifting height for large operations.

Enhanced electronic controls for precision.

Designed for continuous heavy-duty use.

Kalmar Generation

Kalmar Generation models lead the way in electric models for container handling solutions. You benefit from eco-efficient powertrains and smart energy management. Kalmar’s electric models use battery technologies or hydrogen fuel cells. These features help you lower emissions and reduce operational costs.

Kalmar Overview

Aspect | Kalmar Generation Features |

|---|---|

Energy Efficiency | Eco-efficient powertrains with battery or hydrogen fuel cell options |

Operational Costs | Lower service and maintenance costs for electric systems |

Battery Lifespan | Li-Ion batteries last 10-15 years |

Adaptability | Smart energy solutions adjust power settings for performance needs |

Kalmar electric models help you save energy by adjusting power when full strength is not needed.

You can expect lower maintenance costs compared to diesel machines.

Electric models from Kalmar support your move toward greener operations.

Note: When you switch to electric models, review your entire fleet to maximize efficiency and ROI.

Toyota Container Handler

Toyota ranks as a key player in the global forklift reach stacker market. You get reliable container handling solutions with a focus on operator comfort and safety. Toyota’s container handlers work well in tough conditions and offer easy maintenance.

Toyota Overview

Specification | Details |

|---|---|

Capacity | Up to 90,000 lbs (45 Ton) |

Lifting Speed | 47 Feet Per Minute (FPM) |

Engine Type | CUMMINS 6-Cylinder Diesel Engine |

Transmission | Dana model 36000 (3FWD/3REV) |

Safety Features | Operator Restraint System Seat |

Ergonomics | Adjustable air-ride seat |

Visibility | Wide view mast design |

Maintenance | Easy-access filters |

Toyota builds its machines for harsh environments with corrosion protection.

You get an elevated cab and air-ride seat for operator comfort.

Maintenance is simple, which helps you reduce downtime.

Toyota stands among the top brands for container handling solutions, competing with Hyster, Kalmar, and others. The brand’s focus on electric models and operator safety makes it a strong choice for modern warehouses.

Hyster RS46

Hyster Overview

You get a powerful solution with the Hyster RS46. This model stands out in the forklift reach stacker market because of its advanced stability and operator-focused features. Hyster uses patented stabilizer technology that gives you extra side stability and helps reduce tire wear. You can switch attachments quickly with the toolchanger system, which lets you adapt to different cargo types without losing time.

Feature | Description |

|---|---|

Patented Stabilizer Technology | Provides extra side stability and reduces tire wear. |

Toolchanger Attachment | Enables quick switching between different attachments. |

Ergonomic Cab | Offers excellent visibility, noise reduction, and operator comfort. |

Selectable ECO Modes | Enhances fuel efficiency through optimized operation modes. |

Durable Construction | Built with T-1 steel and reinforced welding for longevity. |

Easy Serviceability | Features quick access to components and CANbus diagnostics for maintenance. |

You benefit from an ergonomic cab that gives you clear visibility and reduces noise. The cab design keeps operators comfortable during long shifts. Hyster builds the RS46 with T-1 steel and reinforced welding, so you get a machine that lasts in tough environments. Selectable ECO modes help you save fuel by letting you choose the best setting for your operation. Maintenance is simple because you have quick access to components and CANbus diagnostics.

Tip: If you need a forklift reach stacker that adapts to changing loads and keeps your team safe, the Hyster RS46 is a strong choice.

Taylor Series

Taylor Overview

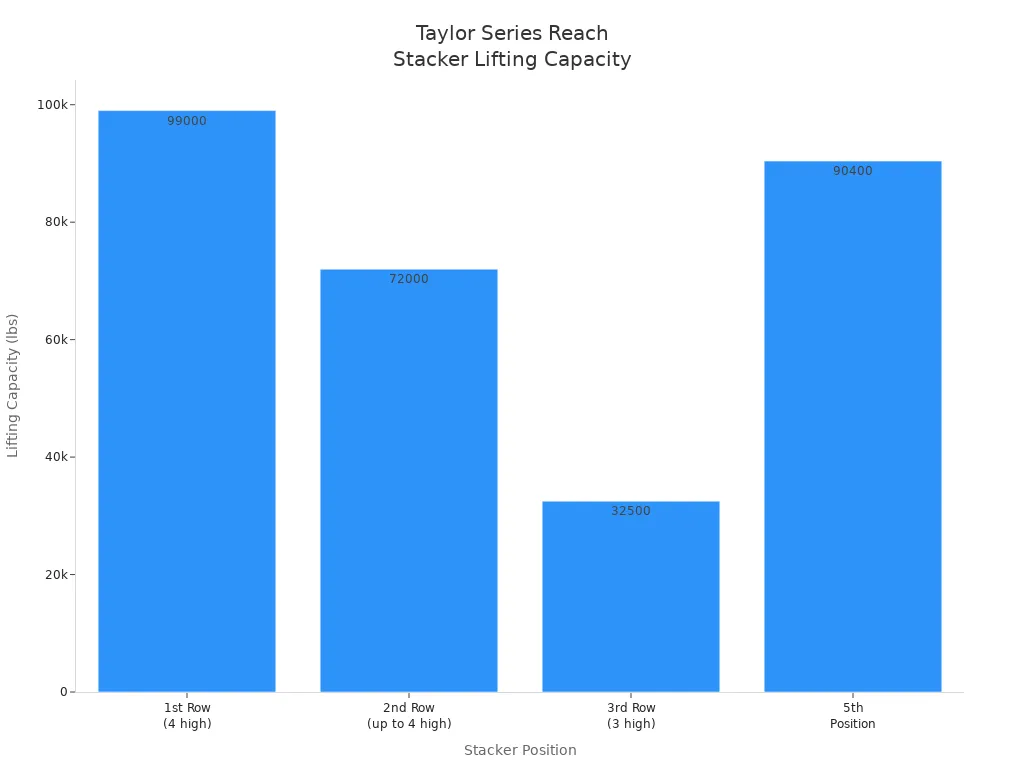

Taylor Series reach stackers give you reliable performance for heavy-duty applications. You can lift up to 99,000 pounds in the first row and handle multiple stacking positions with ease. Taylor uses high-strength steel in the boom construction, which resists fatigue and keeps your machine working longer. The cab moves hydraulically, so you can access maintenance points quickly.

Feature | Specification |

|---|---|

Lifting Capacity (1st Row) | 99,000 pounds (4 high) |

Lifting Capacity (5th Position) | 90,400 pounds |

Lifting Capacity (2nd Row) | 72,000 pounds (up to 4 high) |

Lifting Capacity (3rd Row) | 32,500 pounds (3 high) |

Boom Construction | High-strength steel for fatigue resistance |

Maintenance Features | Hydraulically movable cab for easy access |

Engine Type | Cummins 335-hp electronic diesel engine |

Transmission | Four-speed electronic, automatic powershift |

Visibility | Oversized windows and T-shaped dashboard |

You get robust design and high lifting capacity for different stacking needs. Taylor makes maintenance easy with quick access to components. Operator-friendly features include oversized windows and a T-shaped dashboard, which improve visibility and control. The Cummins 335-hp engine and automatic powershift transmission give you smooth and reliable operation.

Robust design for heavy-duty operations

High lifting capacity for various stacking needs

Ease of maintenance with quick access to components

Operator-friendly features for improved visibility and control

Note: Taylor Series reach stackers work well in busy ports and large warehouses where you need strength and reliability.

XRS-9972

XRS-9972 Overview

You get advanced technology and comfort with the XRS-9972 reach stacker. This model features a climate-controlled cab and ergonomic seating, so operators stay comfortable in any weather. Visibility aids and sophisticated safety systems help you keep your team safe and productive.

Feature | XRS-9972 |

|---|---|

Climate-Controlled Cab | Yes |

Ergonomic Seating | Yes |

Advanced Visibility Aids | Yes |

Safety Systems | Sophisticated control systems, operator presence systems |

Heating Capacity | 66,000 BTU |

Air Conditioning Capacity | 40,000 BTU |

Additional Features | Dual access doors, rear exit window, dome light |

You can handle heavy loads with the XRS-9972. The machine offers a capacity range from 90,000 to 99,000 pounds and a load center of 81 inches. The Volvo 12.8L diesel engine delivers 388 horsepower, and the TE-32 transmission provides smooth shifting. The 5-Hi Boom mast lets you stack containers higher, while hydraulic brakes and large tires improve stability.

Specification | Value |

|---|---|

Capacity | 90k-99k lbs / 41 kg |

Load Center | 81 in. / 2057 mm |

Wheelbase | 258.0 in. / 6553 mm |

Engine | Volvo 12.8L- TAD1371VE-388 4F |

Transmission | TE-32 4-sp. APC |

Mast | 5-Hi Boom |

Brake Type | Hydraulic |

Tires | 18.00 x 25 - 40PR |

Volts | 24 |

Heavy Duty Taylor designed Top-pick 4-point spreader with up to 185 degree rotation

Hydraulic cab positioning

388 HP Tier 4 Final diesel engine

End-User diagnostics for customizable operating parameters and troubleshooting

Versatile machine capable of handling various types of cargo

Tip: The XRS-9972 gives you flexibility and safety for demanding container handling jobs. You can customize operating parameters and troubleshoot issues with end-user diagnostics.

Comparison Table

Specs Overview

When you compare top models in the reach stacker market, you want to see clear differences in performance and value. The table below gives you a quick look at the main specs for each model. You can use this information to match your needs with the right machine.

Model | Max Load (lbs) | Max Stacking Height | Power Type | Price Range (USD) | Notable Feature |

|---|---|---|---|---|---|

TONA-TEC RS-450 | 99,000 | 5-high (9'6") | Diesel | $350,000-$420,000 | High-visibility mast |

TONA-TEC RS-550 | 110,000 | 6-high (8'6") | Diesel | $400,000-$470,000 | Advanced stability design |

TONA-TEC RS-350 | 90,000 | 4-high | Diesel | $320,000-$390,000 | Compact for tight spaces |

TONA-TEC RS-600 | 120,000 | 6-high | Diesel | $450,000-$520,000 | Highest capacity in series |

Kalmar Gen | 99,208 | 5-high | Electric/Hydrogen | $420,000-$500,000 | Eco-efficient powertrains |

Toyota CH | 99,000 | 5-high | Diesel/Electric | $370,000-$440,000 | Operator comfort focus |

Hyster RS46 | 101,000 | 5-high | Diesel | $380,000-$450,000 | Patented stabilizer tech |

Taylor Series | 99,000 | 4-high (1st row) | Diesel | $390,000-$460,000 | Adaptable attachments |

XRS-9972 | 99,000 | 5-high | Diesel | $410,000-$480,000 | Advanced safety systems |

You can see that most models in the reach stacker market offer similar lifting capacities, but stacking height and power options can help you decide which fits your operation best.

Feature Highlights

You want to know what sets each model apart in the reach stacker market. Here are some standout features you should consider:

Many new models use low-emission engines or electric power. These options help you lower your environmental impact and meet new regulations.

Some machines, like the Kalmar Generation, offer battery or hydrogen fuel cell power. You can save on fuel and reduce maintenance costs.

Advanced safety systems, such as operator presence sensors and ergonomic cabs, keep your team safe and comfortable.

Remote control and automation features appear in select models. You can handle cargo from a distance and optimize stacking, which boosts efficiency and safety.

Quick-change attachments and smart diagnostics help you reduce downtime and adapt to different cargo types.

The reach stacker market continues to grow as more companies look for machines that combine strength, efficiency, and smart technology. You can find models that fit small warehouses or large ports. If you want the most advanced features, look for electric or hybrid models with automation and remote control. These options help you stay ahead in a competitive reach stacker market.

Tip: Always match your choice to your specific needs. Consider load size, stacking height, and the latest technology trends in the reach stacker market.

Top Selling Stacker Picks

Best Sellers

You want to know which models lead the reach stacker market in sales. The top selling stacker models for 2024 and 2025 come from a mix of trusted manufacturers. These models offer strong performance, safety, and reliability. You see a wide range of capacities and features, so you can match your needs with the right machine.

Here is a table showing the best sellers in the reach stacker market:

Product Name | Key Features | Capacity | Company |

|---|---|---|---|

Thickened Steel Frame Stacker | CE certified, thickened steel frame, export leader | 200kg–400kg | Guangdong Gongyou Lift Slings Machinery Co., Ltd. |

Electric Stacker 1.2–1.6ton | Top-quality warehouse lifting, export experience | 1.2–1.6 ton | Hangzhou Meetlin Imp.& Exp. Co., Ltd. |

CE Certified Full Electric Stacker | Lightweight, 2000mm driving range, CE-certified | 1500kg | Taizhou Kayond Machinery Co., Ltd. |

Heli Electric Stacker CDD15J | 3M lift height, full electric, export experience | 1500kg | Ningbo Everlift Machinery Co., Ltd. |

Hot Selling Brand Electric Stacker | Stand-on model, export experience | 1.6 ton | Shanghai Jaly Equipment Co., Ltd. |

Hydraulic Stacker Machine | Standing electric, 4m lift height, export experience | 1 ton | Hebei Hugo Machinery Crane Group Co., Ltd. |

1.5t Electric Stacker | 2m lift height, forklift crane, export experience | 1.5t | Shanghai Gather Power Industry Co., Ltd. |

WELIFTRICH Electric Stacker | Lead-acid battery operated, export experience | 1600kg | Welift Machinery (Changzhou) Co., Ltd. |

You see that electric stackers dominate the reach stacker market. These models offer efficient lifting and easy operation. Many companies choose electric stackers for their warehouses and logistics centers.

Why They Stand Out

You may wonder why these models sell so well in the reach stacker market. Several factors drive their popularity. You see growth in seaborne trade, which increases demand for reliable lifting equipment. International trade continues to expand, so companies need machines that handle more cargo. Urbanization also boosts demand for warehouse solutions.

Here is a table showing the main factors behind the success of top selling stacker models:

Factor | Details |

|---|---|

Growth in Seaborne Trade | Maritime trade volume grew by 2.4% in 2023, after a dip in 2022. |

International Trade | US exports reached $256.2 billion in March 2023, up $5.3 billion. |

Rising Urbanization | US population increased by 0.21% in 2022, driving infrastructure needs. |

You benefit from choosing a forklift reach stacker with proven export experience and certifications. These features show that the model meets global standards and performs well in busy environments. Electric stackers stand out because they offer low emissions and easy maintenance. You save time and money with machines that need less service and use less fuel.

Tip: When you select a top selling stacker, look for CE certification, export history, and electric power options. These features help you stay ahead in the reach stacker market and keep your operations running smoothly.

Reach Stacker Market Trends

Market Growth

You see strong momentum in the reach stacker market as you plan for 2025. The global reach stacker market continues to expand, driven by the need for efficient cargo handling in logistics networks and ports. Market analysts project steady growth over the next few years.

The global reach stacker market is expected to reach USD 612 million by the end of 2027.

You can expect a compound annual growth rate (CAGR) of 4.9% from 2021 to 2027.

From 2025 to 2035, the global reach stacker market is projected to expand at a CAGR of 4.3%.

This growth reflects the increasing demand for advanced equipment in both traditional and automated port systems. Many companies now invest in automated models to improve speed and safety. You notice that the reach stacker industry growth also comes from the push for cleaner, more energy-efficient machines. Electric and hybrid models gain popularity as businesses look to reduce emissions and operating costs.

The reach stacker market shows no signs of slowing down. You can expect more innovation and higher adoption rates, especially in regions upgrading their port infrastructure.

Demand Drivers

You play a key role in shaping the reach stacker market through your purchasing decisions. Several important factors drive demand in this industry.

The rise in global trade and container traffic has increased the need for reliable cargo handling. After the pandemic, international trade rebounded quickly. You now see more goods moving through ports and warehouses than ever before. This surge means you need faster and more dependable equipment.

Modernization of port infrastructure also fuels the reach stacker market. Countries invest in automated port systems to stay competitive. These upgrades often include the latest reach stackers, which offer better performance and safety. You benefit from machines that work seamlessly with automated port systems and digital logistics networks.

Environmental regulations shape the reach stacker market as well. Many companies now choose electric-powered reach stackers to meet stricter emissions standards. You help reduce your carbon footprint and support sustainability goals by selecting cleaner equipment.

As you look ahead, you will see the reach stacker market continue to evolve. Automated models, digital integration, and green technology will shape the future of cargo handling.

Buying Guide

Load Capacity

You need to match the load capacity of your reach stacker to your daily operations. If you move standard containers, a model with a capacity of 90,000 to 99,000 pounds will meet most warehouse needs. For heavier loads or stacking higher, look for machines like the TONA-TEC RS-600, which offers up to 120,000 pounds. Always check the maximum stacking height. Some models stack up to six containers high, which helps you maximize storage space. Choose a reach stacker that handles your largest loads without strain. This decision protects your equipment and keeps your workflow smooth.

Tip: Select a reach stacker with a load capacity that matches your busiest days, not just your average workload.

Maneuverability

Maneuverability plays a key role in warehouse efficiency. You want a machine that moves easily in tight spaces and adapts to changing layouts. Modern electric reach stacker models feature advanced steering and adjustable fork heights. These features help you access high shelves and navigate narrow aisles. The compact design of standing reach trucks lets you maximize storage and reduce manual labor.

Feature | Benefit |

|---|---|

Adjustable fork heights | Access high shelves easily |

Advanced steering | Navigate tight spaces |

Flexibility and adaptability | Support rapid changes in operations |

Standing reach trucks enable easy access to hard-to-reach items.

Their compact design maximizes storage capacity.

Efficient movement of pallets reduces manual labor.

The enhanced maneuverability of reach stackers allows you to complete tasks faster. This improvement leads to quicker order fulfillment and higher productivity. Moving mast reach trucks redefine precision positioning, letting you place pallets with accuracy in crowded areas.

Moving mast reach trucks redefine precision positioning, allowing operators to position pallets with unparalleled accuracy, which is crucial in tight spaces.

Technology

Technology in reach stackers continues to evolve. You benefit from automation and digitalization, which make container handling smoother. Intelligent software and sensors optimize movements, improving both efficiency and safety. Many electric reach stacker models now include remote control and autonomous operation features. These upgrades streamline your workflow and reduce the risk of accidents.

Automation and digitalization enhance container handling operations.

Intelligent software and sensors optimize container movements.

Remote control and autonomous operation technologies streamline processes.

Modern reach stackers also include advanced safety features. Smart technology such as collision avoidance and stability control keeps your team safe. Ergonomic designs reduce physical stress, making long shifts easier for operators. When you choose a model with these technologies, you invest in a safer and more productive workplace.

Note: TONA-TEC electric reach stacker models offer smart diagnostics and remote monitoring, helping you maintain peak performance with less downtime.

Safety

You want to keep your team safe when operating reach stackers. Manufacturers now include advanced safety features that help you reduce workplace accidents and protect your investment. You should look for models with the latest safety technology. Here are some important features you will find in top reach stackers:

Emergency Stop Button: Lets you halt the machine instantly during emergencies.

Overload Protection: Stops the stacker from lifting loads that exceed its rated capacity.

Automatic Braking System: Engages brakes to prevent unintended movement.

Visibility Enhancements: Uses LED lights and cameras to improve operator visibility.

Operator Training and Certification: Ensures operators know how to use the equipment safely.

You will notice that brands like TONA-TEC and Kalmar offer these features in their latest models. Emergency stop buttons and overload protection help you avoid costly accidents. Automatic braking systems and visibility enhancements make it easier for operators to work safely, even in busy warehouses. You should also invest in proper training and certification for your team. Well-trained operators use equipment more safely and efficiently.

Tip: Always check for safety certifications and ask about operator training programs when choosing a reach stacker.

Cost

You need to understand the cost of reach stackers before making a purchase. Prices vary based on model, brand, and features. You will find entry-level models at lower prices, while premium models with advanced technology cost more. The table below shows the average price ranges for reach stackers in 2025:

Category | Price Range |

|---|---|

Used Market | $25,000 - $145,000 |

New Entry-Level & Chinese | $80,000 - $330,000 |

Premium New Models | $280,000 - $1,000,000+ |

Value Proposition | $70,000 - $300,000 |

You should consider what features you need most. Premium models like those from TONA-TEC and Kalmar offer advanced safety and technology, but they come at a higher price. Entry-level and value models may fit your budget if you need basic lifting and stacking. Used reach stackers can save you money, but you must check their condition and maintenance history.

Note: Factor in long-term costs such as maintenance, fuel, and repairs. Sometimes, a higher upfront investment leads to lower operating costs over time.

Support

You want reliable support after buying your reach stacker. Leading manufacturers offer strong after-sales services to keep your equipment running smoothly. You should look for brands that provide extended warranties and comprehensive support packages. Here are some support options you will find:

Extended warranty options for major components and wearables, sometimes up to five years.

Replacement parts and service solutions to minimize downtime.

Training courses for operators and technicians to ensure safe and efficient use.

You will benefit from choosing a manufacturer with a proven support network. TONA-TEC and other top brands offer replacement parts and service solutions that help you maintain your stacker. Training courses keep your team updated on best practices. Extended warranties give you peace of mind and protect your investment.

Tip: Ask about warranty coverage and available training when comparing reach stacker brands. Strong support helps you maximize uptime and safety.

Expert Tips

Efficiency

You can boost efficiency in your warehouse by following proven operational strategies. Start by making the best use of your available space. Advanced racking solutions help you store more goods in less area and reduce the number of lift movements. When you eliminate unnecessary staging areas, you improve inventory flow and keep forklift traffic moving smoothly. Planning clear traffic paths prevents congestion and keeps both forklifts and workers safe.

Strategy | Description |

|---|---|

Efficient Space Utilization | Use advanced racking to increase storage density and reduce unnecessary lift movements. |

Consolidate / Eliminate Staging | Remove extra staging areas to improve inventory flow and reduce forklift interference. |

Streamline Traffic Patterns | Design traffic paths to avoid congestion and enhance safety for everyone in the warehouse. |

Increase Container Sizes | Move more goods at once by using larger containers, which reduces the number of trips needed. |

Analyze Route Efficiency | Use warehouse management systems to plan the best routes and picking sequences for forklifts. |

You should also optimize your warehouse layout. Place storage racks in strategic locations and keep aisles wide enough for easy forklift movement. Integrate your forklifts into the layout to ensure smooth movement of goods. Training your operators on efficient driving techniques and proper maintenance will further enhance productivity.

Tip: Choose reach stackers like the TONA-TEC RS Series, which offer advanced maneuverability and smart diagnostics to help you maintain high efficiency.

Safety

Safety must always come first when you operate reach stackers. You should perform pre-operation checks before every shift. Inspect the brakes, hydraulic systems, and warning signals to ensure everything works correctly. Always understand the rated load and safe working area of your machine. Check hydraulic oil, engine oil, and tire pressure before driving.

Safety Protocols | Description |

|---|---|

Pre-Operation Checks | Inspect brakes, hydraulics, and warning signals before each shift. |

Safe Driving Practices | Drive at a controlled speed, keep loads low, and use marked travel paths. |

Load Handling Rules | Never exceed load capacity and always center loads on the forks. |

Awareness of Surroundings | Watch for pedestrians, use horns in blind spots, and keep safe distances. |

Proper Parking | Lower forks, turn off power, and park in designated areas. |

Training Requirements | Ensure all operators are certified and receive regular training. |

Emergency Response | Know how to respond to tipping or spills, including evacuation procedures. |

Use three points of contact when getting on and off the machine. Fasten your seat belt and warm up the engine before starting. Always listen for unusual sounds from the engine. Raise the spreader to maintain visibility while driving. Make sure the fire extinguisher works and never smoke in the cabin. Check for obstacles before adjusting the cab position. Engage the automatic control system before lifting any load.

Note: TONA-TEC reach stackers include advanced safety features such as overload protection and emergency stop buttons to help you maintain a safe work environment.

Training

Proper training ensures you and your team operate reach stackers safely and efficiently. A recommended training program for new operators usually lasts two days. The course covers safety regulations, engineering principles, and daily operation rules. You learn about the responsibilities of a reach stacker operator, how to read data plates, and how to identify hazards.

Aspect | Details |

|---|---|

Duration | 2 Days |

Course Contents | OSHA regulations, engineering principles, load charts, safety components, maintenance |

Objectives | Understand safety laws, apply engineering, identify hazards, improve driving, reduce risks |

Methodology | Lectures, interactive sessions, practical on-site evaluations |

Target Audience | Operators and maintenance supervisors |

You should also learn about hazard identification, risk assessment, and pedestrian safety. Training often includes both classroom instruction and hands-on practice. Regular refresher courses help you stay updated on the latest safety standards and best practices.

Tip: Choose manufacturers like TONA-TEC that offer comprehensive operator training and support to help you maintain high safety and performance standards.

Maintenance

Taking care of your forklift reach stacker keeps your equipment running smoothly and helps you avoid costly repairs. You can extend the lifespan of your machine by following a few key maintenance practices. Start with a regular schedule and make daily checks part of your routine.

Here is a table showing the most important maintenance practices:

Maintenance Practice | Description |

|---|---|

Regular Servicing | Service your stacker every three months or every 250 hours of operation. Early fixes prevent bigger problems. |

Daily Inspections | Check for leaks, damaged parts, and tire condition before you start work. |

Lubrication | Lubricate moving parts as recommended by the manufacturer. This reduces wear and tear. |

Battery Maintenance | Inspect and clean battery terminals often to avoid performance issues. |

Operator Training | Train operators to use the stacker safely and efficiently. Proper use prevents damage. |

You should always perform daily visual inspections before starting your shift. Look for leaks under the machine, check for loose or damaged parts, and inspect the tires for wear or low pressure. Clean your forklift regularly to keep dirt from building up on moving parts. Dirt can cause premature wear and make it harder to spot problems.

Follow the manufacturer's recommended maintenance schedule for servicing and inspections.

Maintain proper tire pressure and replace tires that show signs of damage.

Make sure operators receive training on safe operation and basic maintenance tasks.

Battery care is especially important if you use electric reach stackers. You need to inspect the battery for corrosion, leaks, or damage. Clean the terminals and connections to prevent dirt buildup. Store the battery in a cool, dry place when not in use. Keeping the battery clean and well-maintained helps you avoid unexpected breakdowns.

Tip: Regular maintenance helps you spot small issues before they become major problems. You save money and keep your warehouse running smoothly.

If you use TONA-TEC reach stackers, you benefit from easy-access service points and smart diagnostics. These features make inspections and repairs faster. Always use genuine replacement parts to maintain performance and safety.

You play a key role in keeping your equipment in top shape. When you stick to a maintenance plan, you reduce downtime and extend the life of your reach stacker. Well-maintained machines work better, keep operators safe, and help you meet your daily goals.

Model Recommendations

Heavy-Duty

You need a reach stacker that handles the toughest jobs. Heavy-duty models give you the highest lifting capacities and the strongest frames. These machines work best in ports, rail yards, and large distribution centers. You want a stacker that lifts over 100,000 pounds and stacks containers up to six high.

Top Pick: TONA-TEC RS-600

Model | Max Load (lbs) | Max Stacking Height | Key Feature |

|---|---|---|---|

TONA-TEC RS-600 | 120,000 | 6-high | Advanced hydraulic system |

The TONA-TEC RS-600 stands out for its robust build and advanced hydraulic controls. You get precise handling, even with the heaviest loads. The wide drive axle and reinforced frame give you extra stability. You can use this model for continuous, demanding operations.

Tip: Choose the RS-600 if you need maximum lifting power and reliability for your busiest days.

Budget

You want a reliable reach stacker without breaking your budget. Budget-friendly models offer solid performance and essential features. These machines work well for small to medium warehouses or businesses with lighter workloads.

Recommended: TONA-TEC RS-350

Compact design fits tight spaces.

Handles up to 90,000 pounds.

Uses high-quality components for long life.

Easy maintenance reduces downtime.

The RS-350 gives you the core features you need at a lower price. You save money on both purchase and maintenance. This model works well if you do not need the highest stacking or lifting capacities.

Note: Always check for used or refurbished TONA-TEC models. You can find great value and dependable performance.

Tech-Advanced

You want the latest technology to boost efficiency and safety. Tech-advanced reach stackers include smart diagnostics, automation, and energy-saving features. These machines help you reduce errors and improve workflow.

Best Choice: TONA-TEC RS-450 (Electric Version)

Feature | Benefit |

|---|---|

Smart Diagnostics | Monitors performance and alerts issues |

Remote Monitoring | Tracks usage and maintenance needs |

Energy-Efficient Drive | Lowers fuel costs and emissions |

Ergonomic Cab | Improves operator comfort and safety |

The TONA-TEC RS-450 electric model uses advanced software and sensors. You get real-time data on machine health and usage. Remote monitoring lets you plan maintenance before problems occur. The ergonomic cab and safety systems protect your team.

Tip: Choose a tech-advanced model if you want to future-proof your operations and stay ahead in safety and efficiency.

Compact

When you work in a warehouse with limited space, you need a compact reach stacker. Compact models help you move containers or pallets in tight aisles and crowded storage areas. You save time and reduce the risk of accidents because these machines turn easily and fit where larger stackers cannot go.

Why Choose a Compact Reach Stacker?

You can operate in narrow aisles and small loading docks.

You reduce the turning radius, which helps in crowded environments.

You increase storage density by using every inch of your warehouse.

You lower the risk of damage to goods and racks.

Tip: Compact reach stackers work best in urban warehouses, retail distribution centers, and facilities with high storage racks.

Top Compact Model: TONA-TEC RS-350

TONA-TEC offers the RS-350, a compact reach stacker designed for efficiency in small spaces. You get a strong machine that handles standard containers but does not take up much room. The RS-350 uses high-quality components and advanced safety features.

Feature | TONA-TEC RS-350 Specification |

|---|---|

Max Load Capacity | 90,000 lbs |

Turning Radius | Small, ideal for tight spaces |

Power Source | Diesel |

Stacking Height | Up to 4-high |

Safety Features | Overload protection, clear visibility |

Maintenance | Easy-access service points |

You can rely on the RS-350 for daily operations in busy warehouses. The compact frame lets you move between racks without trouble. The advanced hydraulic system gives you smooth lifting and lowering. You also benefit from overload protection and clear operator visibility.

How to Maximize Compact Stacker Performance

Plan your warehouse layout to match the turning radius of your stacker.

Train your team to use compact models for high-density storage.

Schedule regular maintenance to keep the machine running smoothly.

Use the stacker’s safety features to prevent accidents.

Note: Compact reach stackers like the RS-350 help you boost productivity in small spaces. You get the power of a full-size machine without the bulk.

If you want a machine that fits your space and meets your lifting needs, consider the TONA-TEC RS-350. You will find it easy to operate, safe for your team, and reliable for daily use. Compact reach stackers give you flexibility and efficiency, making them a smart choice for modern warehouses.

You have many strong options for forklift reach stackers. TONA-TEC models stand out for power, safety, and advanced features. For heavy-duty jobs, choose the RS-600. If you want a budget-friendly pick, the RS-350 works well. The RS-450 electric version offers smart technology. Compact spaces call for the RS-350.

Think about your daily needs before you decide. Contact trusted manufacturers like TONA-TEC for expert advice and more details.

FAQ

What is a reach stacker used for?

You use a reach stacker to lift and move shipping containers or heavy pallets in warehouses, ports, and logistics centers. This machine helps you stack containers high and transport them safely.

How do you choose the right reach stacker?

You look at your load size, stacking height, and space. Check the lifting capacity and safety features. TONA-TEC offers models for heavy-duty, compact, and tech-advanced needs.

Are electric reach stackers better than diesel?

You get lower emissions and quieter operation with electric reach stackers. Electric models save you money on fuel and maintenance. Diesel models work well for heavy loads and outdoor use.

How often should you service your reach stacker?

You should service your reach stacker every three months or after 250 hours of use. Daily inspections help you catch problems early and keep your equipment running smoothly.

What safety features should you look for?

You need emergency stop buttons, overload protection, and automatic brakes. Look for LED lights and cameras for better visibility. TONA-TEC reach stackers include advanced safety systems.

Can you operate a reach stacker in tight spaces?

You can use compact reach stackers like the TONA-TEC RS-350 in narrow aisles and crowded warehouses. These models have a small turning radius and easy maneuverability.

Do you need special training to use a reach stacker?

You must complete operator training before using a reach stacker. Training covers safety rules, machine controls, and daily checks. Certified operators help you prevent accidents.

Where can you find reliable reach stacker brands?

You find trusted reach stacker brands at TONA-TEC’s official website. TONA-TEC offers a wide range of models with strong support and warranty options.