When you compare container reach stacker options in 2025, focus on these five essential stats for your container reach stacker: load capacity, stacking height, fuel efficiency, maneuverability, and maintenance reliability. The global container reach stacker market reached USD 2.9 billion in 2024 and is projected to grow at a 5.4% CAGR through 2034. Use these stats as a checklist to boost your yard’s efficiency, control costs, and improve reliability with your container reach stacker.

Statistic | Efficiency Impact | Cost Impact | Reliability Impact |

|---|---|---|---|

Vertical stacking up to 5 containers with a container reach stacker | Yard space +20-30% | Less land needed | Better cargo processing |

Advanced hydraulic systems in container reach stacker | Fuel savings | Lower operations | Reliable handling |

Automated load monitoring for container reach stacker | Fewer accidents | Accident cost down | Higher operational reliability |

Load Capacity

Why Load Capacity Matters

When you choose a container reach stacker, load capacity stands out as one of the most important factors. Load capacity tells you how much weight your machine can safely lift and move. If you work in shipping, logistics, or industrial yards, you handle containers that can weigh anywhere from 30 to 45 tons or more. The lifting capacity of your reach stacker determines if you can move these heavy loads efficiently.

A higher load capacity means you can transport larger containers in fewer trips. This boosts productivity and saves time. You also reduce fuel costs and wear on your equipment. However, you must always respect the load capacity limits. Exceeding these limits can cause accidents and damage your reach stacker. The design and stability of each container reach stacker depend on its lifting capacity. Safe operations require you to match your machine’s load capacity to your daily needs.

Tip: Always check the lifting capacity and maximum lift height before buying a container reach stacker. This ensures you meet your yard’s requirements and keep your team safe.

Container Reach Stacker Model Comparisons

You will find a wide range of load capacities when you compare top container reach stacker models in 2025. Here are some leading options:

Toyota Reach Stacker Container Handler: Load capacity up to 99,000 lbs (50 tons). Maximum lift height reaches industry standards for most container yards.

Sany SRSC45H4: Lifting capacity of up to 99,200 lbs. This model offers reliable performance for medium to heavy-duty operations.

Kalmar Essential Range: Lifting capacity from 45 to 57 tonnes (99,000 to 125,400 lbs). Maximum lift height varies by model, supporting flexible stacking needs.

Konecranes Intermodal Reach Stackers: Lifting capacity between 42 and 46 tons. These machines suit intermodal and port environments.

Heavy-duty reach stackers: Lifting capacity ranges from 120 tonnes (264,000 lbs) to 380 tonnes (837,000 lbs). Maximum lift height and load capacity make these models ideal for specialized industrial applications.

Model | Load Capacity (lbs) | Lifting Capacity (tons) | Maximum Lift Height (ft) |

|---|---|---|---|

Toyota | 99,000 | 50 | Varies |

Sany SRSC45H4 | 99,200 | 45 | Varies |

Kalmar Essential Range | 99,000-125,400 | 45-57 | Varies |

Konecranes Intermodal | 92,400-101,200 | 42-46 | Varies |

Heavy-duty models | 264,000-837,000 | 120-380 | Varies |

You should match the load capacity and lifting capacity of your container reach stacker to the weight and size of the containers you handle most often. Maximum lift height also plays a role in yard layout and stacking efficiency. By understanding these stats, you make smarter choices and improve your operation’s safety and productivity.

Stacking Height

Stacking Height in Container Reach Stackers

Stacking height is a critical factor when you evaluate container reach stackers for your yard. The maximum stacking height determines how many containers you can stack vertically, which directly affects your storage capacity and yard layout. Most modern reach stackers offer impressive stacking height capabilities. For example, the SRSC45H4 model can stack containers up to five high. Some reach stackers designed for empty and semi-laden containers can reach a stacking height of eight high and three deep. This allows you to maximize your available space and improve operational efficiency.

Model | Maximum Stacking Height | Depth |

|---|---|---|

Reachstacker for empty/semi-laden containers | 8 high | 3 deep |

SRSC45H4 | 5 high | — |

Stacking height capability influences how you arrange and manage container stacks. Higher stacking height means you can store more containers in the same footprint. This reduces the need for extra land and helps you optimize your yard layout. You also improve throughput because you spend less time moving containers around. Efficient stack optimization lowers handling times and increases overall throughput. Density stacking lets you handle higher container volumes without changing your yard handling systems.

Aspect | Impact on Efficiency |

|---|---|

Stacking Height Capability | Influences arrangement and management of container stacks, affecting operational workflow and access times. |

Stack Optimization | Reduces container handling times and increases throughput, minimizing unnecessary relocations. |

Density Stacking | Allows for higher container volumes without changing yard handling systems, improving space utilization. |

Tip: Always match the stacking height of your reach stacker to your yard’s needs. Higher stacking height gives you more flexibility and better space utilization.

Forklift Comparisons

When you compare stacking height between reach stackers and forklifts, you see clear operational advantages. Reach stackers are designed for high stacking in compact spaces. They provide excellent space utilization in container yards. Some reach stackers can stack containers up to five high, while specialized models reach eight high. Forklifts, especially reach trucks, can lift loads to heights over 30 feet. They work well for multilevel storage configurations and offer versatility for different applications.

Equipment Type | Stacking Height | Operational Advantage |

|---|---|---|

Reach Stackers | Up to five high | Efficiently stack containers in compact spaces, maximizing storage capacity. |

Forklifts | Over 30 feet | Versatile and higher load capacities for various applications. |

You should consider forklift comparisons when planning your yard layout. Reach stackers give you higher stacking height in tight spaces, while forklifts offer flexibility and can handle a variety of loads. Both equipment types help you improve your yard’s efficiency, but reach stackers excel in maximizing stacking height and space utilization.

Fuel Efficiency

Energy Consumption

Fuel efficiency plays a big role in the daily cost and environmental impact of your container reach stacker. You want a machine that uses less fuel but still delivers strong performance. Different models have different fuel consumption rates. Knowing these numbers helps you plan your budget and choose the right equipment for your yard.

Here is a quick look at average fuel consumption rates for top container reach stacker models in 2025:

Model | Fuel Consumption Rate |

|---|---|

Reach stacker/top (RS) | 5.00 L/km |

Standard diesel-driven top loader | 16 L/hour |

45t reachstacker | 8-10 L/hour |

You can see that a standard diesel-driven top loader uses about 16 liters of fuel per hour. A 45-ton reach stacker uses between 8 and 10 liters per hour. These numbers help you estimate your fuel costs and compare models. Lower fuel consumption means you spend less on fuel and reduce your carbon footprint. If you operate your reach stacker for many hours each day, even small differences in fuel efficiency can add up to big savings over time.

Tip: Always check the fuel consumption rate before you buy. This stat affects both your operating costs and your environmental impact.

Eco-Friendly Options

You have more eco-friendly choices than ever before. Manufacturers now offer electric and hybrid reach stackers that help you meet strict emission regulations and lower your environmental impact.

Electric reach stackers produce fewer emissions and run more quietly than diesel models.

Hybrid reach stackers use both diesel engines and electric batteries. This combination reduces emissions and improves fuel efficiency.

Many new models meet tough emission standards, making them a smart choice for sustainable operations.

Advances in battery technology make electric reach stackers more powerful and practical for busy yards.

Choosing an eco-friendly reach stacker helps you save on fuel, reduce noise, and support a cleaner environment. These options also prepare your business for future regulations and customer demands for green logistics.

Maneuverability

Turning Radius

You need a container reach stacker that moves easily in tight spaces. The turning radius tells you how sharply your machine can turn. A smaller turning radius lets you work in narrow aisles and crowded yards. You save time when you maneuver around obstacles or stack containers close together. Operators find it easier to position containers exactly where they need them.

Manufacturers design reach stackers with advanced steering systems. Some models use rear-wheel steering for better control. Others offer multi-mode steering, which helps you handle complex layouts. You should check the specifications for each model. Compare the turning radius to your yard’s layout. If your facility has narrow lanes or limited space, choose a reach stacker with a compact turning radius.

Tip: Test the reach stacker in your yard before you buy. Make sure it can turn smoothly in your busiest areas.

Yard Suitability

You want a reach stacker that fits your yard’s needs. Yard suitability depends on several factors.

Lifting capacity for different stacking rows and container weights.

Types and sizes of containers or materials you handle most often.

Maneuverability requirements, including turning radius and ability to work in narrow aisles.

Reliability of drivetrain components, such as engine and gearbox brands.

Availability of spare parts and maintenance support.

Required reach and stacking height based on your facility layout.

Technological features like telematics, eco-friendly powertrains, and load-sensing safety systems.

Operator comfort and safety features, including ergonomic controls and safety switches.

The specific environment where your machine will operate.

Budget considerations, covering both initial and ongoing costs.

You should match your reach stacker to your yard’s layout and daily operations. If you handle heavy containers, choose a model with higher lifting capacity. If your yard has narrow aisles, prioritize maneuverability. Look for models with reliable engines and easy access to spare parts. Consider new features like telematics and eco-friendly engines. These options help you save money and improve safety.

Note: Review your yard’s layout and container flow before you select a reach stacker. This helps you avoid costly mistakes and boosts efficiency.

Maintenance & Reliability

Downtime & Service

You want your container reach stacker to work every day with minimal interruptions. Downtime can slow your operations and increase costs. When you select a reach stacker, focus on reliability. Machines with high reliability need fewer repairs and keep your yard running smoothly. You should look for models with easy access to service points. This design feature allows technicians to complete maintenance tasks quickly. Regular service schedules help prevent unexpected breakdowns and support long-term reliability.

Operators play a key role in reliability. Well-trained staff can spot early signs of wear or damage. You should encourage daily inspections and routine checks. These habits reduce downtime and improve reliability. Many modern reach stackers include telematics systems. These systems monitor performance and alert you to maintenance needs. You can schedule service before problems grow. This proactive approach increases reliability and keeps your equipment in top condition.

Tip: Choose a reach stacker with a strong service network. Fast access to parts and skilled technicians boosts reliability and reduces downtime.

Warranty & Support

Warranty and support packages show how much confidence a manufacturer has in their equipment’s reliability. You should compare warranty terms before you buy. Longer warranties and strong support services protect your investment and improve reliability. In 2025, leading manufacturers offer advanced support features. For example, Konecranes gives you access to a cloud-based customer portal. You can view usage and maintenance data, which helps you track reliability over time. SANY provides a three-year, 6,000-hour standard product warranty. This strong warranty backing covers all equipment and supports reliability.

Manufacturer | Warranty Details | Support Features |

|---|---|---|

Konecranes | Access to a cloud-based customer portal for usage and maintenance data | Transparent view of service events and activities |

SANY | Three-year, 6,000-hour standard product warranty | Strong warranty backing for all equipment |

You should use these support tools to monitor reliability and plan maintenance. Reliable support means you get help fast when you need it. This reduces downtime and keeps your reach stacker working. Always choose a manufacturer with a reputation for reliability and strong after-sales service. These factors ensure your equipment delivers consistent performance year after year.

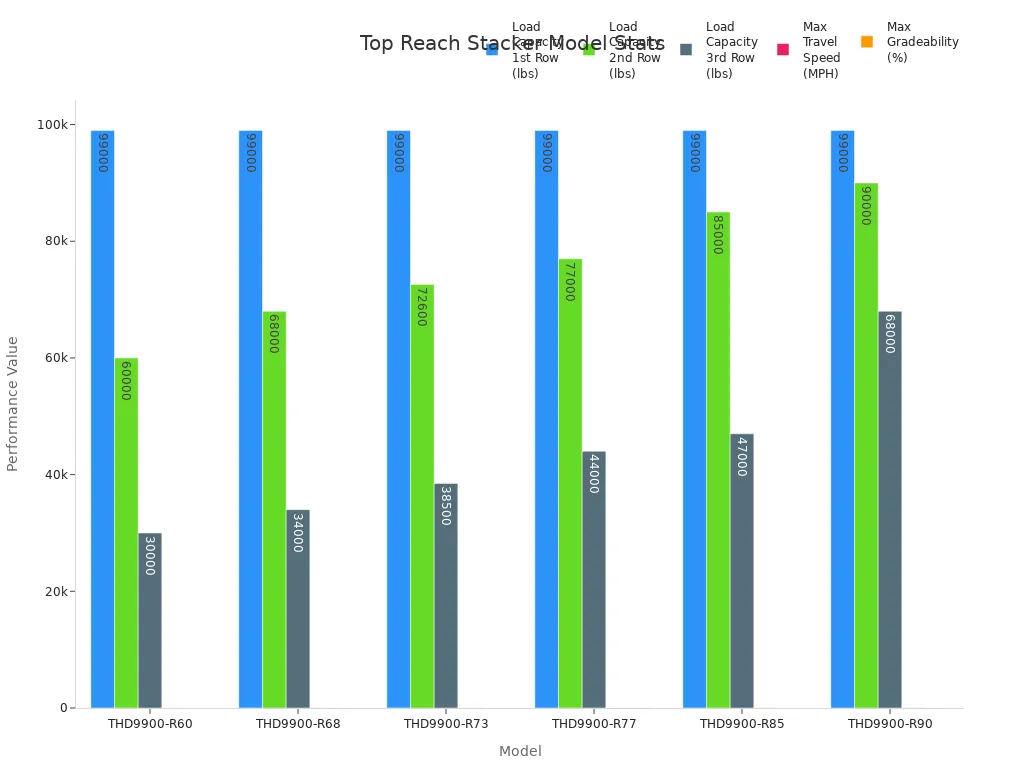

Top Reach Stacker Models Comparison

When you compare top reach stacker models, you want to see how each machine performs in the areas that matter most. You need to look at load capacity, stacking height, fuel efficiency, maneuverability, and maintenance reliability. These stats help you choose the right equipment for your yard or terminal.

Quick Stats Table

The table below shows how the top reach stacker models stack up across five key categories. You can use this side-by-side comparison to find the best fit for your operation.

Model/Series | Max Lifting Capacity | Stacking Height | Fuel Efficiency Features | Maneuverability & Tech | Reliability & Maintenance |

|---|---|---|---|---|---|

Kalmar DRG Series | 45-70 tons | Up to 5 high | Up to 40% fuel savings, HVO fuel | Kalmar Insight, ergonomic cab | Overload protection, easy service |

Konecranes SMV Series | 10-46 tons | Up to 5 high | HVO100 biofuel, Power/Flow Drive | OPTIMA cabin, TRUCONNECT | Fire suppression, collision warning |

Hyster RS46 | 30-46 tons | Up to 5 high | Selectable ECO modes | Ergonomic cab, diagnostics | Patented stabilizer, reinforced boom |

Liebherr LRS 545 | 45 tons | Up to 5 high | Hybrid option, low fuel use | Hydrostatic drive, LED lights | Local service, robust build |

SANY SRSC45H | 45 tons | Up to 5 high | Load-sensing hydraulics | Safety sensors, ergonomic controls | Reverse camera, object detection |

XCMG Electric Reach Stacker | 10-45 tons | Up to 5 high | Zero emissions, fast charging | Distributed motor drive | Anti-tip, weight sensors |

Toyota Reach Stacker | 10-45 tons | Up to 5 high | Eco-efficient engine | Advanced safety, ergonomic cab | Multiple safety systems |

You can see that most top reach stacker models offer strong lifting capacity and stacking height. Many feature eco-friendly engines or hybrid options to help you save fuel and meet emission standards. Advanced cabins and safety technology improve maneuverability and operator comfort. Maintenance features like overload protection and easy access to service points help you keep downtime low.

Tip: Use this table to compare top reach stacker models before you make a decision. Look for the features that match your yard’s needs and budget.

You should also check the availability of these models at trusted suppliers like tona-tec.com. Reliable support and service can make a big difference in your daily operations.

Choosing the right container reach stacker depends on five key stats: load capacity, stacking height, fuel efficiency, maneuverability, and maintenance reliability. You should use these stats as a checklist to compare models and make smart decisions. Manufacturers update container reach stacker models often, adding new technology like telematics and automation. Real-world data shows that high-speed container reach stacker units improve throughput and reduce turnaround times. The latest trends include electric and hybrid container reach stacker models, IoT integration, and stricter safety standards.

Trend/Technology | Description |

|---|---|

Automation and Sustainability | Electric and hybrid container reach stacker models lower emissions and costs. |

IoT and AI Integration | Smart container reach stacker units use sensors for predictive maintenance. |

You should always consult suppliers and review real-world performance before buying a container reach stacker. Stay updated on market changes and new features to maximize your long-term investment.

FAQ

What is the main difference between reach stackers and forklifts in container handling?

You use reach stackers for heavy container handling and high stacking. Forklifts work best for lighter loads and lower stacking heights. Reach stackers offer greater capacity and performance for efficient port operations, while forklifts provide flexibility for warehouse operations and smaller material handling tasks.

How do I choose the right capacity for my container handling needs?

You should match the capacity of your equipment to the weight and size of containers you move most often. Check the specs for each model. Higher capacity improves performance and safety in container handling, especially for popular use cases in ports and warehouses.

Why is technology integration important in modern forklifts and reach stackers?

Technology integration boosts performance, safety, and eco-efficiency features. You benefit from telematics, load sensors, and automation. These upgrades help you track capacity, reduce downtime, and support efficient port operations. Many popular forklift models now include advanced technology for better material handling.

What are the most popular forklift models for warehouse operations?

Popular forklift models include Toyota, Hyster, and Konecranes. These brands offer strong capacity, reliable performance, and advanced technology integration. You can find detailed specs and options for container handling and warehouse operations at trusted suppliers like tona-tec.com.

How do eco-efficiency features impact container handling performance?

Eco-efficiency features lower fuel use and emissions. You save money and support green goals. These features improve performance and capacity for container handling. Electric and hybrid forklifts and reach stackers now lead the market in eco-friendly material handling.