Modern container terminals rely on the power and precision of the Reach Stacker. This machine can lift heavy containers, sometimes weighing up to 45 tons, and stack them several rows high. Operators use Reach Stackers to move containers quickly, even in tight and crowded spaces. These machines work faster than many other types of equipment and help reduce congestion at busy ports. Advanced features, such as energy-efficient engines and user-friendly controls, also support safety and environmental goals.

Key Takeaways

Reach stackers lift heavy containers and stack them high, saving space and speeding up container handling in busy terminals.

Their compact design and strong steering let operators move containers easily in tight spaces, reducing congestion and wait times.

Using reach stackers lowers costs by replacing multiple machines, improving yard space use, and cutting labor and maintenance expenses.

Modern reach stackers include safety features like sensors and stability controls that protect workers and prevent accidents.

New technologies and eco-friendly engines make reach stackers more efficient and help terminals reduce emissions and operate sustainably.

Reach Stacker Basics

What Is a Reach Stacker?

A Reach Stacker is a powerful machine used in ports, railway stations, and container yards. It helps move, lift, and stack shipping containers quickly and safely. Operators use this equipment to load and unload containers from ships, trucks, and trains. The machine can handle heavy loads, sometimes up to 45 tons, and can stack containers several rows high and deep. This ability makes it essential for busy terminals where space is limited.

Tip: Reach stackers combine the functions of a crane and a forklift, making them very versatile for different cargo handling tasks.

There are different types of reach stackers. Heavy-duty reach stackers can lift the heaviest containers, while lightweight models are better for smaller loads or tight spaces. Popular models include the TR4645 Reach Stacker, TR45 Reach Stacker, and TR4535 Reach Stacker. Each model offers unique features to meet the needs of various operations.

Key Features

Reach stackers have several features that set them apart from other container handling equipment:

High lifting capacity for heavy containers

Telescoping boom for stacking containers multiple rows deep and up to five high

Flexible operation in tight spaces due to a compact design and strong steering system

Advanced safety features like load sensors, stability controls, and ergonomic cabins

Attachments such as spreaders and lifting beams for secure container handling

Powerful engines that balance strength and fuel efficiency

Automation options, including remote control and smart technology, for improved safety and productivity

These features allow reach stackers to move containers efficiently across a terminal, optimize storage space, and speed up loading and unloading. Their design helps reduce turnaround times for ships, trucks, and trains, making them a key part of modern logistics.

Advantages

Flexibility

A Reach Stacker gives operators the ability to move containers in many directions. It can lift containers from the top, stack them in several rows, and reach over other containers. This flexibility helps workers handle containers in tight spaces where other machines cannot fit. Operators can use a Reach Stacker to pick up containers from different heights and angles. This makes it easier to organize the yard and keep operations running smoothly. Compared to forklifts or traditional container stackers, a Reach Stacker can access containers in the middle or back rows without moving others first. This saves time and reduces extra work.

Efficiency

Terminals need to move containers quickly to keep up with busy schedules. A Reach Stacker helps speed up these operations. It can load and unload containers from ships, trucks, and trains faster than many other machines. Operators use its strong lifting power and advanced controls to reduce waiting times for vehicles. The machine’s ability to stack containers higher and deeper also helps maximize yard space.

Reach stackers offer exceptional maneuverability, allowing operation in confined spaces and navigation of tight corners, which reduces waiting times for ships, trucks, and trains.

Their speed and ability to quickly load and unload containers minimize operational downtime and increase productivity.

They can handle heavy containers efficiently and stack them higher, optimizing yard space and reducing congestion.

These capabilities collectively lead to faster container movements, minimized downtime, increased throughput, and thus faster turnaround times and improved port productivity.

Data from industry reports shows that new technologies, such as AI-driven maintenance and automation, make reach stackers even more efficient. These features help reduce unplanned downtime and improve the life of the equipment. As a result, terminals can handle more containers in less time, even when space and labor are limited.

Cost-Effectiveness

A Reach Stacker can help terminals save money in several ways. It can do the work of several machines, so companies do not need to buy as many different types of equipment. Its ability to stack containers in multiple rows and heights means terminals use their space better, which can delay or avoid the need for expansion.

Reach stackers reduce handling times, lowering labor costs and increasing cargo throughput.

Their flexibility allows handling various cargo types, reducing the need for multiple specialized machines and associated maintenance costs.

They optimize space by stacking containers efficiently, maximizing terminal yard usage.

Reach stackers reduce manual labor requirements, enhancing safety and further cutting labor expenses.

Their reliability and durability minimize downtime and maintenance costs, contributing to overall cost efficiency.

The design of a Reach Stacker also makes maintenance easier and less expensive than some other machines. With proper care, these machines last a long time and keep working well. This leads to lower operating costs and a better return on investment for terminal operators.

Safety & Environment

Modern reach stackers include many safety features to protect workers and equipment. These features help prevent accidents and make the workplace safer for everyone.

Safety Feature | Description and Role in Accident Reduction |

|---|---|

Proximity Sensors and Alarms | Detect nearby objects and pedestrians; alert operators to prevent collisions. |

Collision Avoidance Systems | Use sensors and cameras to detect obstacles and automatically brake or adjust path to avoid collisions. |

Stability Control Systems | Monitor balance and load distribution; adjust movement to maintain stability and prevent tip-overs. |

Operator Assistance Systems | Provide real-time guidance and feedback for precise handling and maneuvering, reducing operator errors. |

Ergonomic Design | Features like adjustable seats and controls reduce operator fatigue, enhancing safety. |

Overload Protection Systems | Prevent operation beyond safe load limits, protecting equipment and operators. |

Anti-tip Devices | Mechanisms to prevent tipping accidents during operation. |

Automatic Speed Control | Adjusts speed based on load and terrain to prevent over-speeding and maintain control. |

Enhanced Visibility | Includes 360-degree cameras, mirrors, and LED lighting to improve operator awareness of surroundings. |

Emergency Stop Functions | Allow immediate shutdown of equipment in emergencies to prevent accidents. |

Many reach stackers now use electric or hybrid engines. These engines use less fuel and produce fewer emissions. This helps terminals meet environmental rules and reduce air pollution. By stacking containers higher, reach stackers also help terminals use less land, which supports sustainability. Automation and digital controls further improve efficiency and reduce the impact on the environment. As technology advances, future reach stackers will likely use even cleaner energy sources, making container handling greener.

Applications

Ports & Railway Stations

Busy ports and railway stations rely on the Reach Stacker to move containers quickly and safely. Workers use these machines to lift containers from ships, trains, and trucks. The Reach Stacker can stack containers several rows high, which helps save space in crowded yards. Operators often choose models like the TR4645 Reach Stacker for heavy loads or the TR4535 Reach Stacker for tight spaces. These machines help keep goods moving, even when space is limited.

Intermodal Operations

Intermodal operations involve moving containers between ships, trains, and trucks. The Reach Stacker plays a key role in these activities. Operators can switch between different tasks using toolchanger attachments. This reduces the need for many machines. The strong steel frame and heavy-duty axle give the Reach Stacker a long life and make it easy to steer. Patented stabilizer technology keeps the machine steady and helps tires last longer. Operator cabins have large windows, comfortable seats, and controls that reduce noise and vibration. These features help workers stay alert and safe. Advanced hydraulic systems and ECO modes save fuel and keep the machine running smoothly. Operators can use remote controls to pick up containers without extra help. Electronic weight scales prevent overloads and keep the work safe.

Operators can handle containers up to the third row across rail tracks and road lanes.

High lifting capacity and stability allow for safe movement of heavy containers.

Remote control operation lets one person do the job without extra helpers.

Adjustable cabins and electronic scales improve comfort and safety.

Case Studies

Many ports and logistics hubs have improved their operations by using reach stackers. For example, a large port in Asia uses the TR45 Reach Stacker to move containers between ships and trains. This model helps the port handle more containers each day. A railway station in Europe uses the TR4645 Reach Stacker to stack containers higher and save yard space. Operators report that these machines are sturdy and easy to use. They also say that the machines help reduce waiting times and improve safety. These real-world examples show how reach stackers support busy terminals and help them grow.

Choosing the Right Reach Stacker

Selecting the right reach stacker is important for any container terminal. Operators must consider several factors to ensure efficient and safe operations.

Capacity & Performance

Capacity and performance are the first things to check. Each terminal handles different container weights and stacking heights. Some terminals need to lift containers up to 45 tons and stack them several rows high. The size of the hydraulic cylinder affects how much weight the machine can lift. Larger cylinders help lift heavier containers and improve stability. Smaller cylinders work well for lighter loads and allow faster, more precise movements. Operators should also look at the type of cargo, stacking height limits, and the layout of the terminal. Many modern reach stackers offer advanced control systems, safety features, and attachments for different cargo types. These features help terminals handle more containers and improve productivity.

Maneuverability

Maneuverability is key in crowded terminals. A reach stacker with a compact design and 360-degree rotation can move easily in tight spaces. This ability helps operators navigate narrow aisles and stack containers in high-density areas. Features like ergonomic steering, advanced hydraulic systems, and telescopic arms make it easier to handle containers safely and quickly. Good maneuverability reduces congestion and waiting times, which increases overall efficiency. Electric models also offer smooth and quiet operation, making them suitable for busy environments.

Tip: Always match the maneuverability of the reach stacker to the space and layout of your terminal for best results.

Purchase vs. Rental

Terminals must decide whether to purchase or rent a reach stacker. Buying offers long-term savings and full control over the equipment. It works best for terminals with steady, high-volume needs. Renting provides flexibility and lower upfront costs. It suits terminals with changing demands or short-term projects. Rental agreements often include maintenance, which reduces downtime and unexpected expenses. Operators should weigh their budget, operational needs, and future growth before making a decision.

Option | Best For | Key Benefits |

|---|---|---|

Purchase | Long-term, steady use | Cost savings, asset control |

Rental | Short-term, flexible use | Flexibility, lower upfront cost |

Future Trends

Technology

Modern Reach Stacker technology continues to advance at a rapid pace. Manufacturers now use automation and robotics to create machines that can drive themselves. These autonomous systems help reduce manual labor and improve efficiency. Many terminals use the Internet of Things (IoT) to monitor equipment in real time. This technology allows operators to track machine health, predict maintenance needs, and optimize usage. Artificial intelligence (AI) helps with smart route planning and navigation. AI also processes data from sensors to improve safety and reduce accidents.

Operators benefit from new features like GPS, load sensors, and fleet management software. These tools provide real-time data and analytics. They help terminals handle containers faster and use less fuel. Materials and automation improvements make each Heavy-Duty Reach Stacker and Lightweight Reach Stacker more reliable and capable. Electric and hybrid models are becoming more common, especially in areas with strict environmental rules. These machines help reduce carbon footprints and lower operating costs.

Note: Automation and digitalization make container handling safer and more efficient. Remote control and autonomous operation allow for better fleet management and less downtime.

Sustainability

Sustainability is a top priority for container terminals. Many companies now use electric-powered and hydrogen fuel cell Reach Stacker models. These machines produce fewer emissions and help meet environmental regulations. Some terminals, like MSC Terminal Valencia, have tested hydrogen and electric reach stackers. Others, such as Asyaport in Turkey, use solar panels to generate renewable energy for their equipment.

Use of green steel in manufacturing reduces carbon in each TR4645 Reach Stacker and TR45 Reach Stacker.

Operators replace cast-iron counterweights with natural materials to lower embedded carbon.

Eco Driving Training and Tyre Pressure Monitoring Systems help save energy and extend equipment life.

Long-lifetime hydraulic oil and electric models further cut emissions.

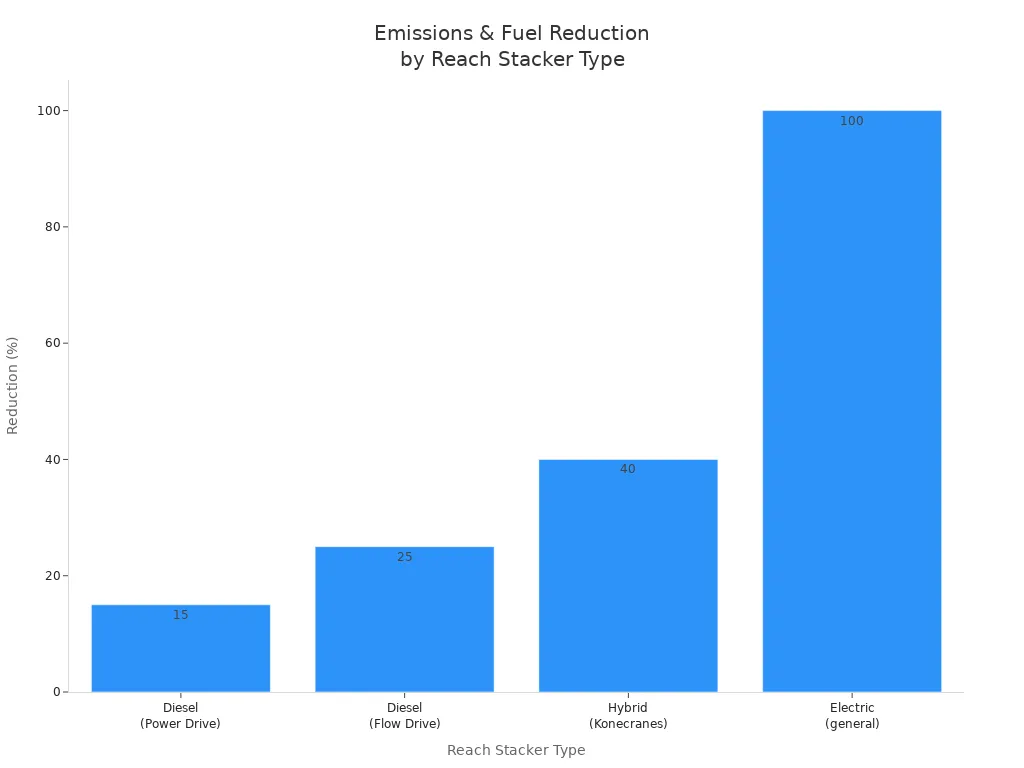

Reach Stacker Type | Emissions & Fuel Consumption Reduction | Key Technical Features | Cost Savings & Efficiency |

|---|---|---|---|

Diesel (Power Drive) | ~15% fuel reduction | Engine speed limited, modified hydraulics | Small initial cost, recovered in 1 year |

Diesel (Flow Drive) | Up to 25% fuel reduction | Hydromechanical Variable Transmission (HVT) | Higher initial cost, payback in 2 years |

Hybrid (Konecranes) | Up to 40% reduction in fuel and emissions | Energy recovery, 'silent mode', electric motors for propulsion and lifting | 70% cost savings over 8 years, lower servicing costs |

Electric (general) | Zero emissions during operation | Battery powered, regenerative braking | Lower energy costs, no diesel fuel consumption |

These trends show that the future of Reach Stacker for Efficient Container Handling will focus on cleaner energy, smarter technology, and better resource use. Terminals that adopt these innovations will lead the way in green logistics.

A Reach Stacker plays a vital role in modern container terminals. Operators see many benefits:

They speed up loading and unloading, reducing downtime.

Their strong lifting power allows higher stacking and better use of space.

They move easily in tight areas, preventing congestion.

They help lower costs by reducing the need for extra machines.

Modern models support eco-friendly operations.

Decision-makers can future-proof their terminals by choosing advanced reach stackers with smart sensors and digital systems. These tools help track containers, improve planning, and keep operations efficient.

FAQ

What is the main job of a Reach Stacker?

A Reach Stacker moves and stacks shipping containers in ports, railway stations, and container yards. It lifts heavy loads, saves space, and helps workers organize containers quickly and safely.

How does a Heavy-Duty Reach Stacker differ from a Lightweight Reach Stacker?

A Heavy-Duty Reach Stacker lifts heavier containers and works best in large terminals. A Lightweight Reach Stacker handles smaller loads and fits better in tight spaces or smaller yards.

Why choose the TR4645 Reach Stacker or TR45 Reach Stacker?

Operators pick the TR4645 Reach Stacker or TR45 Reach Stacker for their strong lifting power, advanced safety features, and easy controls. These models help terminals move more containers with less effort.

Can a terminal rent a Reach Stacker instead of buying one?

Yes, terminals can rent a Reach Stacker. Renting offers flexibility and lower upfront costs. It works well for short-term projects or changing needs. Buying suits long-term, steady use.