A Reach Stacker helps you move and stack shipping containers quickly and safely. You find this machine essential for ports, railways, and busy container yards.

You can lift heavy containers, sometimes over 30 tons, with ease.

The boom lets you stack containers high, saving space.

You work in tight spots thanks to great maneuverability.

Fast operation means less waiting and more work done.

You use just one machine for many container sizes, making your job simpler.

Key Takeaways

Reach stackers lift and move heavy shipping containers quickly and safely, making them essential for ports, rail yards, and container yards.

These machines stack containers high and deep, saving space and improving yard organization and productivity.

You can choose between heavy-duty models for large loads and lightweight models for smaller spaces and faster work.

Key features include strong lifting capacity, long boom reach, smart hydraulics, remote monitoring, and advanced safety systems.

Always follow safety rules, get proper training, and perform daily maintenance to keep your reach stacker running smoothly and safely.

Reach Stacker Basics

What Is a Reach Stacker

You use a reach stacker to lift and move shipping containers. This machine helps you handle heavy loads in ports, rail yards, and storage areas. A reach stacker can pick up containers, stack them high, and place them in tight spaces. You find it different from a forklift or a reach truck. A forklift lifts loads from the bottom and works best with pallets. A reach truck moves items in warehouses and has a smaller reach. A reach stacker, on the other hand, handles much heavier loads and reaches farther. You choose a reach stacker when you need to move large containers quickly and safely.

Tip: If you work in a busy port or rail yard, a reach stacker gives you more flexibility and speed than other machines.

How It Works

A reach stacker uses a strong boom to grab and lift containers. The boom extends forward and upward, so you can stack containers several rows deep and high. You control the boom with a hydraulic system. This system lets you move containers smoothly and with great precision. Stabilizers on the sides of the machine keep it steady when you lift heavy loads. You operate the controls from a comfortable cab with good visibility. The machine’s design helps you work safely and efficiently, even in tight spaces.

Here is a simple table showing the main components of a reach stacker:

Component | Function |

|---|---|

Boom | Lifts and extends to reach containers |

Hydraulics | Powers the boom and lifting mechanism |

Stabilizers | Keeps the machine steady during heavy lifts |

You can see that each part plays a key role in making the reach stacker a powerful tool for container handling.

Applications

Ports and Railways

You often see a reach stacker working in busy ports and railway stations. This machine helps you move containers between ships, trucks, and trains. You can stack containers higher and deeper, which saves space in crowded yards. Many ports, like the Port of Shanghai, use reach stackers to handle large numbers of containers every day. In European rail terminals, you use them to transfer containers quickly between trains and trucks.

Here are some common ways you use a reach stacker in ports and railways:

Move containers between different types of transport, such as ships, trains, and trucks.

Stack containers in tall rows to make the best use of yard space.

Load and unload containers from railcars and trailers.

Work in tight spaces where larger cranes cannot fit.

Operate efficiently and safely, thanks to advanced safety features.

You choose a reach stacker for ports and railway stations because it gives you flexibility and speed. You also save money compared to using large cranes or many forklifts.

Container Handling

You rely on a reach stacker for efficient container handling in warehouses and storage yards. This machine lets you lift heavy containers and place them exactly where you need them. You can organize your storage area by stacking containers in several rows and columns. This helps you use every inch of space.

A reach stacker makes your job easier by:

Allowing you to move containers quickly from one spot to another.

Helping you load and unload containers with less effort.

Making it simple to handle containers of different sizes.

Giving you control and precision, even in small or crowded areas.

Tip: When you use a reach stacker for efficient container handling, you finish your work faster and keep your yard organized.

Types of Reach Stacker

Heavy-Duty

You use a heavy-duty reach stacker when you need to lift the heaviest containers. These machines handle large loads, often up to 99,000 pounds. Heavy-duty models work best in busy ports and rail yards where you move many containers every day. You get strong booms, powerful hydraulics, and advanced safety features. Heavy-duty reach stackers can stack containers up to five high and reach three rows deep. You also find options for smart displays and safety cameras, which help you work faster and safer.

Lightweight

You choose a lightweight reach stacker for smaller jobs or tight spaces. These machines weigh less and use less fuel. You can move them easily around warehouses or smaller container yards. Lightweight models still lift heavy loads, but they focus on speed and flexibility. You save money on fuel and maintenance. You also find that lightweight reach stackers are easier to operate in areas with limited space.

Tip: If you work in a small yard or need to move containers quickly, a lightweight reach stacker gives you the best mix of speed and efficiency.

Popular Models

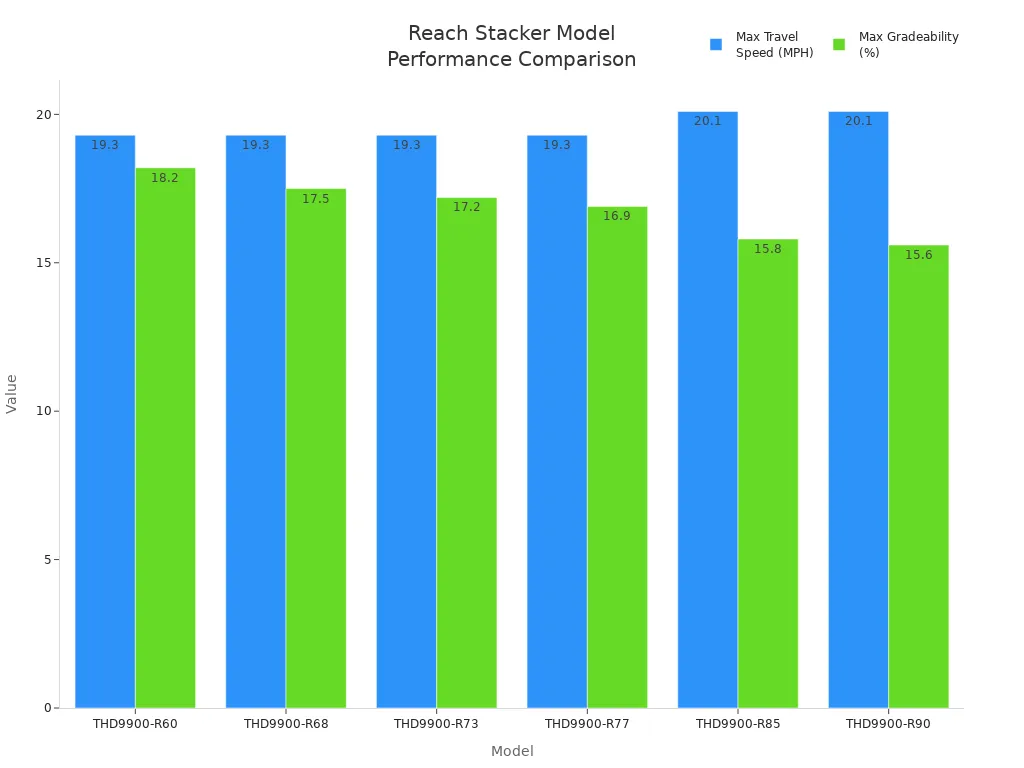

You have many models to choose from, each with unique features. The TR4645, TR45, and TR4535 are popular choices for many operators. These models offer different lifting capacities and reach options. You can compare them with other top models using the table below:

Model | Load Capacity (lbs) (1st/2nd/3rd row) | Max Travel Speed (MPH) | Max Lift Speed (FPM) | Max Gradeability (%) | Basic Right Angle Stack (inches) |

|---|---|---|---|---|---|

THD9900-R60 | 99,000 / 60,000 / 30,000 | 19.3 | 60 | 18.2 | 480 (20') / 565 (40') |

THD9900-R68 | 99,000 / 68,000 / 34,000 | 19.3 | 60 | 17.5 | 480 / 565 |

THD9900-R73 | 99,000 / 72,600 / 38,500 | 19.3 | 60 | 17.2 | 480 / 565 |

THD9900-R77 | 99,000 / 77,000 / 44,000 | 19.3 | 60 | 16.9 | 480 / 565 |

THD9900-R85 | 99,000 / 85,000 / 47,000 | 20.1 | 60 | 15.8 | 508 / 586 |

THD9900-R90 | 99,000 / 90,000 / 68,000 | 20.1 | 60 | 15.6 | 508 / 586 |

You see that each model offers different strengths. Some models focus on higher lifting capacity, while others give you more speed or better gradeability. Many models include features like touchscreen displays, safety cameras, and radar systems.

When you choose the right reach stacker, think about your daily needs. If you handle heavy loads in a large port, pick a heavy-duty model. If you work in a smaller yard, a lightweight model may fit better. Always match the machine to your workload and space.

Features and Benefits

Key Features

You get many important features when you use this equipment. The lifting capacity lets you move very heavy containers with ease. The boom reach helps you stack containers high and deep in your yard. Smart hydraulics give you smooth and precise control. You can lift, lower, and move containers exactly where you want them. Many machines now offer remote monitoring. This feature lets you check the status of your equipment from a distance. You can track performance, spot problems early, and plan maintenance before issues grow.

Here is a quick list of key features you will find:

High lifting capacity for heavy loads

Long boom reach for stacking multiple rows

Smart hydraulic systems for smooth operation

Remote monitoring for easy equipment checks

Comfortable cab with clear visibility

Advanced safety systems to protect you and your team

Tip: Use remote monitoring to keep your machine in top shape and avoid unexpected downtime.

Advantages

You gain many advantages when you choose this equipment over forklifts or other machines. You can handle larger containers and stack them higher. This saves space and makes your yard more organized. You work faster because you move more containers in less time. The machine uses fuel efficiently, so you save money on every job. You also get more versatility. You can use one machine for many container sizes and types.

A table below shows how this equipment compares to a standard forklift:

Feature | This Equipment | Forklift |

|---|---|---|

Lifting Capacity | Very High | Moderate |

Boom Reach | Long | Short |

Fuel Efficiency | High | Moderate |

Versatility | Excellent | Limited |

Stacking Height | Up to 5 containers | Up to 2 containers |

You see that this equipment gives you more power, reach, and flexibility. You finish your work faster and use less fuel.

Safety and Maintenance

Safety Tips

You must always put safety first when you operate a reach stacker. This machine can lift very heavy loads, so you need to follow strict rules. Wear a hard hat, safety vest, and steel-toed boots every time you work. Check your Heavy-Duty Reach Stacker or Lightweight Reach Stacker before you start. Look for leaks, worn tires, or loose parts. Never use a machine that looks damaged.

You need special training to use a reach stacker. In the United States, you must get OSHA certification. Here are the main steps:

Complete an approved training program that covers OSHA rules, safety tips, driving skills, and stacker maintenance.

Pass a written test about safe operation.

Show your skills in a hands-on test with a qualified trainer.

Take a safety test to prove you can use the machine safely.

You can learn through lectures, videos, or online classes.

Tip: Always keep your certification up to date. This helps you stay safe and follow the law.

Maintenance Needs

You keep your Reach Stacker for Efficient Container Handling running well with regular care. Clean the cab and windows so you can see clearly. Check the oil, hydraulic fluid, and coolant every day. Make sure the boom and stabilizers move smoothly. Grease all moving parts to stop rust and wear.

You should follow a simple routine:

Inspect the TR4645 Reach Stacker, TR45 Reach Stacker, or TR4535 Reach Stacker before each shift.

Replace worn-out parts right away.

Test the brakes, lights, and alarms often.

Keep a logbook for all repairs and checks.

A well-maintained machine lasts longer and works better. You avoid costly breakdowns and keep your team safe. Choose the right reach stacker and take care of it every day for the best results.

You have learned that these machines offer many advantages for your logistics operations.

You can handle different container sizes and weights, often lifting up to 45 tons.

You stack containers high, which saves space and boosts yard capacity.

You work quickly and safely in busy areas, improving productivity.

You lower costs by using one machine for many jobs and choosing models that fit your needs.

You support sustainability with energy-efficient options.

Before you choose a Reach Stacker, review your daily tasks and space. Talk to experts for advice. Stay safe and keep your container handling efficient.

FAQ

What is the main use of a reach stacker?

You use a reach stacker to lift, move, and stack shipping containers. This machine works best in ports, rail yards, and warehouses. You can handle heavy loads and organize containers efficiently.

How do you choose the right reach stacker for your needs?

You look at your daily workload, container sizes, and yard space. You compare models like the TR4645 Reach Stacker, TR45 Reach Stacker, and TR4535 Reach Stacker. You pick a Heavy-Duty Reach Stacker for big jobs or a Lightweight Reach Stacker for smaller spaces.

What safety steps should you follow when using a reach stacker?

You always wear safety gear. You inspect your machine before use. You get proper training and certification. You follow all safety rules to protect yourself and your team.

How often should you maintain your reach stacker?

You check your Reach Stacker for Efficient Container Handling every day. You inspect fluids, brakes, and moving parts. You schedule regular maintenance to keep your machine running smoothly and safely.

Related Blogs

-

Have you ever wondered how ports move massive containers so quickly? Reach stackers are the machines behind the magic, combining power and precision to handle heavy loads. Learning how to operate a reach stacker is critical for safety and efficiency. Mistakes can cause accidents, equipment damage, or delays in port operations. This guide is made for port workers, warehouse staff, and logistics personnel. In this post, you’ll learn how to operate a reach stacker safely and step by step, even if you're just starting out.blogs

Have you ever wondered how ports move massive containers so quickly? Reach stackers are the machines behind the magic, combining power and precision to handle heavy loads. Learning how to operate a reach stacker is critical for safety and efficiency. Mistakes can cause accidents, equipment damage, or delays in port operations. This guide is made for port workers, warehouse staff, and logistics personnel. In this post, you’ll learn how to operate a reach stacker safely and step by step, even if you're just starting out.blogs