If you want to know what is a reach stacker, you should picture a powerful vehicle designed to move and lift heavy shipping containers. You use a reach stacker to handle intermodal cargo containers safely and efficiently. This machine lets you stack containers on top of each other or place them in tight spaces.

With a reach stacker, you gain the ability to transport large containers quickly in busy ports, train yards, or storage areas.

What is a reach stacker

Definition

When you ask, "what is a reach stacker," you discover a specialized vehicle designed for moving and stacking shipping containers in terminals and distribution centers. You see a reach stacker equipped with a hydraulic gantry system. This system allows you to reach containers stacked in several rows, making it possible to load and unload containers from trucks, trains, or storage areas with ease. The telescopic boom stands out as a key feature. You can extend this boom to access containers placed up to five high, which is not possible with most other container handling equipment.

You notice the compact design of a reach stacker. The heavy-duty chassis and large rubber tires give you stability and control, even when you handle heavy containers. This design lets you operate in tight spaces, unlike larger cranes or forklifts. If you work in a busy port or a crowded yard, you rely on a reach stacker to move containers quickly and safely.

Tip: When you need to handle containers in areas with limited space, a reach stacker offers the flexibility and maneuverability you require.

Main Function

If you want to understand what is a reach stacker used for, you should look at its main functions in container terminals. You use a reach stacker to lift, move, and stack intermodal containers. The telescopic boom lets you lift containers vertically and move them horizontally, so you can place them exactly where you need them.

Here is a table that shows the primary functions of a reach stacker:

Function | Description |

|---|---|

Lifting | You can lift intermodal containers efficiently using the telescopic boom. |

Moving | You move containers both horizontally and vertically with precision. |

Stacking | You stack containers at different heights and distances in the yard. |

You find reach stackers essential for handling intermodal containers in shipping ports. Their unique design gives you versatility in container management. Safety features help you operate securely, even when you handle containers of different sizes.

When you use a reach stacker, you help your port handle more containers in less time. You increase efficiency by allowing faster movement and stacking of containers. You optimize yard space by stacking containers higher and deeper. This means you reduce turnaround times for ships and vehicles, which boosts overall productivity. You also prevent congestion and bottlenecks, so other port activities can continue smoothly.

You enable faster movement of containers, keeping operations flowing in busy ports.

You optimize space by stacking containers higher and deeper.

You reduce turnaround times, making your port more profitable and competitive.

You help prevent congestion and bottlenecks, ensuring smooth loading and unloading.

If you want to know what is a reach stacker and why it matters, you should remember its ability to lift, move, and stack containers efficiently. You rely on this machine to keep your cargo operations running smoothly.

Reach stacker operation

Components

When you operate a reach stacker, you rely on several key components that work together to move and stack containers. Each part plays a specific role in the machine’s performance and safety. Here is a table that shows the main components and their functions:

Component | Role in Operation |

|---|---|

Hydraulic system | Enables lifting and positioning of containers; includes cylinders, pumps, valves, etc. |

Engine components | Provides necessary power for heavy lifting; includes fuel injection system, pistons, etc. |

Electrical system | Ensures smooth operation; includes batteries, alternators, wiring harnesses, etc. |

Structure and chassis | Provides strength and stability; includes masts, booms, axles, wheels, etc. |

Brake system | Critical for safety and performance; includes brake shoes, pads, calipers, etc. |

You use the hydraulic system to lift containers with precision. The engine gives you the power to handle heavy loads. The electrical system keeps all controls responsive. The structure and chassis support the weight and keep the reach stacker stable. The brake system helps you stop safely, even when you carry a full load.

How it works

You control the reach stacker from a cab with clear visibility. You use joysticks and pedals to operate the hydraulic lifting mechanism. The telescopic boom extends and retracts, letting you reach containers stacked high or placed deep in the yard. You can move containers both vertically and horizontally, which makes stacking and organizing much easier.

Here is a table that explains how the reach stacker handles containers:

Capability | Description |

|---|---|

Immense Lifting Capacity | Can lift laden containers weighing tens of tons (e.g., 20-45 metric tons). |

High Stacking Ability | Capable of stacking containers multiple high (e.g., 5-6 high) and often multiple deep (e.g., 3-4 deep). |

Mobility | Being wheeled, they can move containers relatively quickly around the yard. |

Telescopic Boom | The extendable boom allows containers to be placed or retrieved from rows not directly adjacent to the machine. |

You use retractable hooks to secure containers before lifting. Rotating forks help you handle different cargo types. Advanced steering systems let you navigate tight spaces, such as between trailers or railway wagons. Safety features like overload protection and stability control keep your operations secure. You can rely on reach stackers to move containers from trailers, railway wagons, or storage yards with speed and accuracy.

Tip: If you want reliable performance and advanced features, consider reach stackers from brands like TONA-TEC. These machines offer strong lifting capacity and excellent maneuverability for busy container terminals.

Reach stacker uses

Container handling

You use a reach stacker to manage containers in busy ports, rail yards, and storage facilities. This machine gives you the ability to lift, move, and stack containers with speed and precision. You can handle both loaded and empty containers, which helps you keep operations running smoothly. When you need to organize containers in tight spaces, you rely on the reach stacker’s telescopic boom and advanced controls.

Note: You increase efficiency and safety when you use a reach stacker for container handling. The operator’s cab provides clear visibility, which helps you avoid accidents and damage.

Here are some ways a reach stacker improves container handling compared to other equipment:

You reach high-stacked containers quickly, which speeds up loading and unloading and reduces downtime.

You benefit from excellent lifting capacity, so you handle heavy and empty containers efficiently.

You experience lower operational costs because of the machine’s durability and reliability.

You achieve faster turnaround times, which leads to higher customer satisfaction and increased throughput.

You find that reach stackers play a key role in material handling at intermodal terminals. You can move containers from trailers, railway wagons, or storage yards without delays. If you want to maximize space and boost productivity, you choose a reach stacker for your container operations.

Other applications

You also use reach stackers for other material handling tasks beyond containers. In some industries, you move large steel coils, timber, or bulky cargo. You adapt the spreader or lifting attachment to suit different loads. This flexibility makes the reach stacker valuable in manufacturing plants and logistics centers.

You can transport oversized items that do not fit standard containers. You use the reach stacker’s strong chassis and hydraulic system to lift heavy goods safely. Some models, such as those from TONA-TEC, offer specialized attachments for unique material handling needs.

Tip: If you want a versatile solution for your yard, consider a reach stacker with customizable features. You handle a wide range of cargo types and improve your workflow.

You rely on the reach stacker for efficient material handling in many settings. You save time and reduce labor costs by using one machine for multiple tasks.

Features and benefits

Lifting capacity

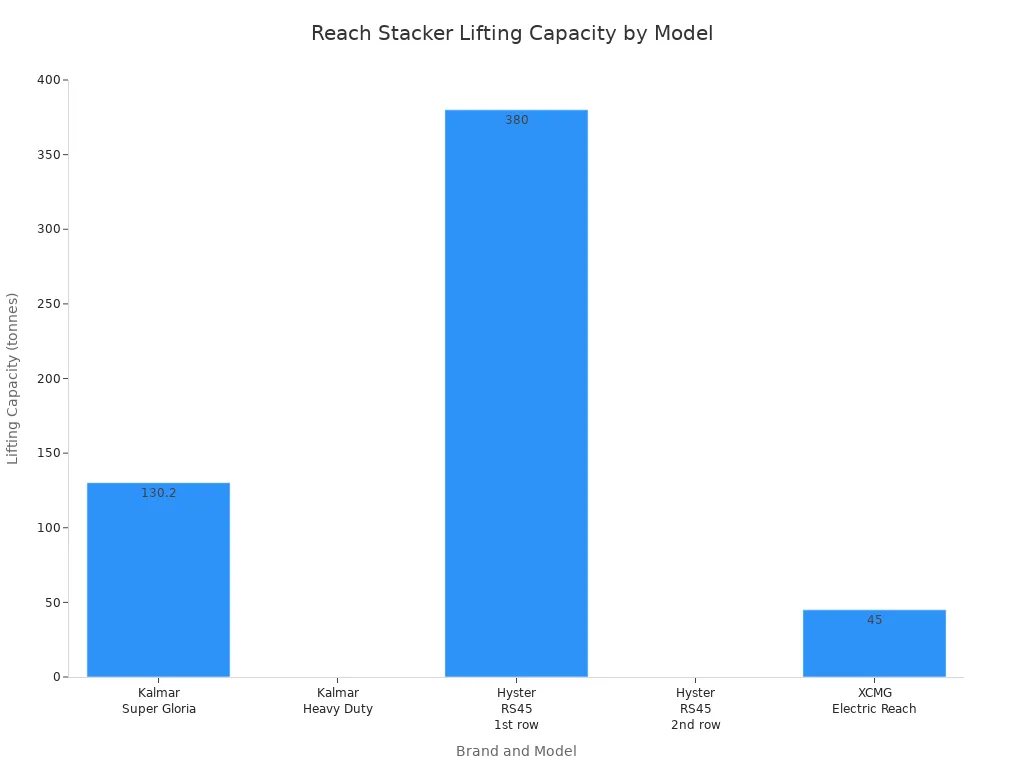

You need a machine that can handle heavy loads with ease. Modern reach stackers offer impressive lifting capacities, making them suitable for a wide range of cargo. For example, some models from Kalmar, Hyster, and XCMG can lift between 45 tons and up to 380 tons. TONA-TEC also provides robust models designed for demanding environments. Here is a comparison of lifting capacities among popular brands:

Brand | Model | Lifting Capacity |

|---|---|---|

Kalmar | Super Gloria | up to 287,000 lbs |

Kalmar | Heavy Duty | up to 380 tons |

Hyster | RS45 | 45 tonnes (1st row) |

Hyster | RS45 | 27 to 31 tonnes (2nd row) |

XCMG | Electric Reach Stacker | up to 45 tons |

Stacking height

You can stack containers higher than ever before with today’s reach stackers. Most modern machines reach over 10 meters (about 33 feet). This ability allows you to create tall stacks, which saves valuable yard space. When you use a reach stacker to build tall stacks, you help your facility move more cargo without expanding the yard. Strategic stacking policies, including careful attention to stack height, play a key role in optimizing space and improving the flow of containers. Real-time data helps you adjust stacking strategies as cargo flow changes.

Maneuverability

You often work in tight spaces, so maneuverability matters. Reach stackers feature a compact design that lets you navigate narrow aisles and sharp corners. This design helps you handle stacked containers even in crowded yards. Features like flexible wheel setups and advanced steering systems allow you to move quickly and safely. Proper load distribution and regular maintenance further improve handling and safety. Increased mobility leads to faster workflows and fewer delays.

Advantages

You gain several advantages when you choose a reach stacker over a forklift for container handling. Here is a summary:

Advantage | Description |

|---|---|

High Reach | Access containers stacked high, reducing the need for extra equipment. |

Heavy Load Capacity | Handle heavy containers efficiently for various cargo tasks. |

Cost-Effectiveness | Use one machine for multiple jobs, lowering equipment and maintenance costs. |

Durability and Reliability | Get consistent performance with proper care, reducing downtime and expenses. |

Maneuverability and Speed | Move quickly in tight spaces, boosting operational efficiency. |

You also benefit from flexibility in multi-modal operations. Some models, such as those from TONA-TEC and Konecranes, can handle different types of cargo, including trailers and swap bodies. Smart hydraulics adjust lifting power based on the load, making your work even more efficient.

Tip: When you need to move heavy or awkward loads in a busy terminal, a reach stacker gives you the power, reach, and flexibility to get the job done right.

Types of reach stackers

Standard models

You find standard reach stackers in most container terminals and industrial yards. These machines offer reliable performance for everyday container handling tasks. You choose from different capacity types, propulsion systems, and fuel options to match your operational needs. The table below shows common types of standard reach stackers available in the market:

Capacity Type | Propulsion Type | Fuel Type | Application Type |

|---|---|---|---|

Below 30 Ton | Internal Combustion Engine | Compressed Natural Gas | Sea Port/Terminal |

30-45 Ton | Electric | Liquified Petroleum Gas | Yards/Landside |

Above 45 Ton | Hybrid | Industrial |

You select a model based on the weight of containers you handle and the environment where you work. Electric models help you reduce emissions in enclosed spaces. Hybrid options give you flexibility and efficiency for heavy-duty tasks. Many brands, such as TONA-TEC, offer a range of standard reach stackers designed for durability and ease of use.

Tip: When you need a dependable machine for routine container stacking, a standard reach stacker gives you the right balance of power and maneuverability.

Specialized models

You encounter specialized reach stackers when you face unique container handling challenges. These machines feature custom designs, advanced technology, and tailored attachments. You use them for oversized cargo, hazardous materials, or intermodal operations. The table below highlights specialized models and their features:

Model Type | Features |

|---|---|

Custom Reach Stackers | Tailored solutions for unique operational needs, specific lifting capacities, specialized dimensions, automated technology. |

Intermodal Handling Stackers | Designed for intermodal container handling, exceptional power, stability, and maneuverability. Can handle containers up to the third row across rail tracks and road lanes. |

Specialized models give you high flexibility and performance.

You lift containers with exceptional power and stability.

You handle heavy-duty tasks with a long wheelbase and large lifting capacities.

You solve problems like limited visibility by using innovative camera and sensor systems. OPTIMA cabin solutions improve your view and safety. TRUCONNECT remote monitoring services help you optimize productivity and reduce downtime. Specialized handling attachments protect containers from damage during lifting and stacking.

If you need to automate your yard operations, you can choose automated reach stackers. These models use advanced controls and sensors to move containers with minimal human intervention. You improve efficiency and safety in busy terminals.

Note: TONA-TEC offers specialized reach stackers with custom features for challenging environments. You can find models designed for hazardous cargo or oversized loads.

You use a reach stacker to lift, move, and stack containers in ports and storage yards. This machine gives you speed, safety, and versatility for cargo management.

You boost productivity and save costs by handling more containers with fewer machines.

Advanced safety features help protect you and your cargo.

Leading brands like Konecranes, Kalmar, and Hyster-Yale offer reliable models with smart technology.

Factor | Why It Matters |

|---|---|

Lifting Capacity | Matches your operational needs |

Maneuverability | Helps in tight spaces |

Safety Features | Protects operators and cargo |

Explore trusted products from TONA-TEC for efficient container handling and long-term support.

FAQ

What is the difference between a reach stacker and a forklift?

You use a reach stacker for lifting and stacking heavy containers. Forklifts handle smaller loads and cannot reach as high. Reach stackers move containers both vertically and horizontally, making them ideal for ports and rail yards.

How much weight can a reach stacker lift?

You can lift containers weighing up to 45 tons with most reach stackers. Some specialized models, like those from TONA-TEC, offer even higher lifting capacities for demanding tasks.

Where can you use a reach stacker?

You operate reach stackers in shipping ports, rail yards, and storage facilities. You also use them in manufacturing plants for moving large or bulky cargo. Their flexibility helps you handle many types of loads.

Tip: Choose a reach stacker with features that match your work environment for best results.

How do you maintain a reach stacker?

You check hydraulic systems, tires, and safety controls regularly. You follow the manufacturer’s maintenance schedule. Proper care helps you extend the life of your reach stacker and keeps operations safe.

Which brands offer reliable reach stackers?

You find reliable reach stackers from brands like TONA-TEC. Their products provide strong lifting capacity, advanced safety features, and easy operation. You can explore more options on their official website.