Choosing the right electric reach stacker for your business can feel overwhelming. You want to match your equipment to your space and daily tasks. Look for these key factors: load capacity, lift height, aisle width, battery life, safety, energy source, and eco-friendliness.

Good advice helps you avoid costly mistakes. Take advice from experts and consider each feature carefully before you decide.

Electric Reach Stacker Features

Load Capacity

Assessing Maximum Load

When you choose an electric reach stacker, start by evaluating the maximum weight your operations require. Each model comes with a specific load capacity, which tells you the heaviest load it can safely lift and move. You should never exceed this limit. Overloading can cause instability, tipping, and equipment failure. Always check the manufacturer's rating before making a decision.

Here is a quick overview of typical load capacities available in the market:

Load Capacity Range | Description |

|---|---|

Less Than 10 Tons | Dominates the market for warehouses and smaller logistics centers handling lighter loads. |

10–15 Tons | Fastest-growing segment for medium-sized terminals and manufacturing units with increased needs. |

More Than 15 Tons | Common in ports and heavy industrial facilities managing large containers and bulk materials. |

If your business handles mostly pallets and boxes, a model like the TONA-TEC 1.5-ton or 2-ton electric reach stacker may fit your needs. For heavier loads, consider models designed for 10 tons or more.

Safety Margin

You should always build in a safety margin when selecting your electric reach stacker. Never push the machine to its absolute limit. Exceeding the recommended load can lead to serious hazards:

Hazard Type | Consequences |

|---|---|

Overloading | - Tipped stackers can severely injure the operator or nearby workers. |

- It can cause damage to the load or equipment. | |

Tip-Over Incidents | - Severe injuries to the operator or nearby workers. |

- Damage to the machine and surroundings. |

Each electric stacker and pallet truck has a specified load capacity.

Never exceed the recommended weight limits.

Overloading can lead to instability, tipping, and equipment failure.

Tip: Choose a stacker with a load capacity at least 10% higher than your heaviest regular load. This extra margin helps protect both your staff and your investment.

Lift Height

Racking System

The lift height of your electric reach stacker determines how high you can store goods. You need to match the stacker’s reach to your warehouse racking system. If your racks go up to 7 meters, your stacker must reach at least that high. TONA-TEC offers models with various lift heights to suit different warehouse layouts.

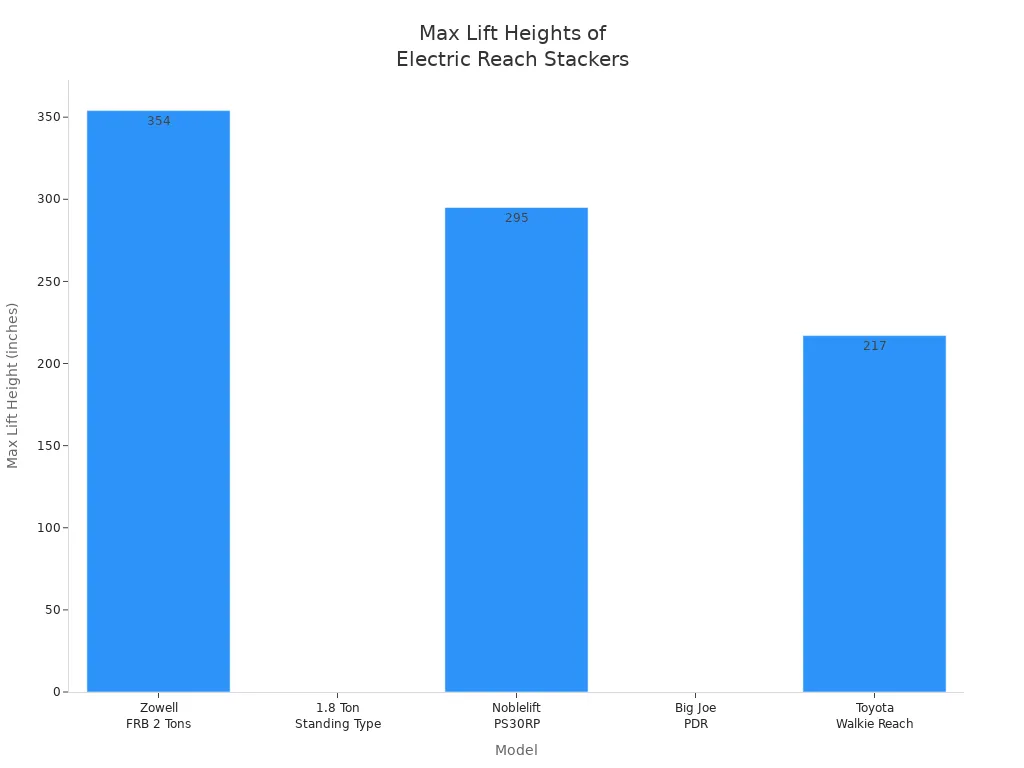

Here are some standard lift heights from leading manufacturers:

Model | Maximum Lift Height |

|---|---|

Zowell FRB 2 Tons Electric Reach Truck | 9m |

1.8 Ton Standing Type Electric Reach Truck | 7.5m |

Noblelift PS30RP | 114"-217" |

Big Joe PDR | 106"-194" |

Toyota Walkie Reach Stacker | Up to 189 in. |

Maximum Reach

Increasing your warehouse’s clear height allows you to install taller racking systems. This means you can store more products without expanding your building. High-density storage systems, such as Vertical Lift Modules (VLMs), help you use vertical space efficiently. You can manage more inventory in the same area, which reduces the need for outside storage. Using vertical space also improves operational efficiency by making picking and packing faster and easier.

Note: When you select a stacker, always check that its maximum lift height matches your tallest rack. This ensures you can access every level safely and efficiently.

Aisle Width

Warehouse Space

Aisle width plays a big role in choosing the right electric reach stacker. The type of forklift you use determines how narrow your aisles can be. Here is a comparison:

Forklift Type | Aisle Width Requirement |

|---|---|

Conventional Forklifts | 12 to 13 feet |

Narrow Aisle Forklifts | 8 to 10 feet |

Very Narrow Aisle Forklifts | 6 feet or less |

If you want to maximize storage, narrow aisle or very narrow aisle stackers are the best choice. TONA-TEC offers models designed for tight spaces, helping you fit more racks and pallets in your warehouse.

Maneuverability

The specifications of your electric reach stacker, such as headlength and turning radius, affect how easily you can move in tight spaces. Narrower aisles mean you can store more pallets, but you need a stacker that can operate safely within those constraints. The difference between a 118-inch and a 127-inch aisle could mean thousands of lost pallet positions over time.

The specifications of reach trucks, including headlength and required aisle widths, affect storage capacity.

Narrower aisles require specific types of reach trucks that can operate effectively within those constraints.

The choice of forklift, rack depth, and pallet length all play a part in defining aisle width. Narrow aisle reach trucks allow for tighter racking layouts, which boosts your storage density and efficiency.

Tip: Measure your warehouse aisles before you buy. Make sure your chosen electric reach stacker can turn and operate safely in your space.

Battery Life

Usage Patterns

Battery life plays a major role in how well your electric reachstacker fits your daily operations. You need to think about how often you use your equipment and how long each shift lasts. If your warehouse runs multiple shifts, you want a battery that can keep up without frequent downtime. Some batteries require long charging periods, which can slow down your workflow.

You can choose between lead-acid and lithium-ion batteries. Each type has strengths and weaknesses:

Battery Type | Lifespan | Charging Time |

|---|---|---|

Lead-Acid | Shorter (dependent on maintenance) | ~8 hours (plus cooling) |

Lithium-Ion | 2-3 times longer | < 2 hours (opportunity charging) |

Lead-acid batteries need about 8 hours to charge and require a cooling period. You may need extra batteries for continuous use.

Lithium-ion batteries charge in less than 2 hours. You can top them up during short breaks, which keeps your electric reachstacker running all day.

Tip: If your business needs fast turnaround and long operating hours, consider models like the TONA-TEC lithium-ion reach stackers. These units support opportunity charging and help you avoid costly downtime.

Charging Options

Charging options affect your workflow and energy costs. Some electric reachstackers use traditional charging stations, while others support rapid or opportunity charging. Lithium-ion batteries allow you to charge during lunch breaks or shift changes, which means you do not need to swap batteries or stop work.

Lead-acid batteries require dedicated charging rooms and careful maintenance.

Lithium-ion batteries offer flexible charging and longer life, which reduces replacement costs.

You should match your battery choice to your usage pattern. If you run single shifts with long breaks, lead-acid batteries may work. For busy warehouses with multiple shifts, lithium-ion batteries provide better efficiency.

Note: Always check the battery specifications before you buy. TONA-TEC offers electric reachstackers with advanced lithium-ion technology, which can help you save time and energy.

Safety

Standard Features

Safety features protect your team and your products. International standards require electric reachstackers to include several key safety systems. You should look for these features when comparing models:

Safety Feature | Description |

|---|---|

Load safety indicator | Shows the weight of the load to prevent overloading. |

Anti-slip traction | Keeps the stacker stable on slick surfaces. |

Emergency stop button | Lets you stop the machine instantly in an emergency. |

Adjustable forks | Secure and stabilize different load sizes. |

Tilt protection | Prevents the stacker from tilting too far, reducing the risk of falling loads. |

Low battery indicator | Warns you when the battery is low, so you can avoid sudden shutdowns. |

Many TONA-TEC electric reachstackers include these standard safety features. You can find models with load safety indicators and emergency stop buttons, which help prevent accidents and keep your warehouse safe.

Advanced Technologies

Advanced safety technologies make your workplace even safer. Automatic braking systems stop the stacker when you release the control handle, which prevents accidental movement. Stability controls help keep the stacker balanced, even in busy aisles or on uneven floors.

Automatic braking reduces accidents in crowded spaces.

Stability controls maintain balance and prevent tipping.

Ergonomic designs improve visibility, lowering the risk of collisions.

Advanced sensors detect obstacles and slow down the stacker in tight areas.

Height-adjustment mechanisms stop the stacker from lifting beyond its safe limit.

Callout: TONA-TEC electric reachstackers offer advanced safety features like automatic braking and stability control. These technologies help you protect your staff and reduce workplace accidents.

You should always choose a stacker with both standard and advanced safety features. This ensures your team can work confidently and efficiently.

Operational Needs

Choosing the right electric reach stacker starts with understanding your operation’s unique needs. You should look at your business size, the types of loads you handle, and how often you use your equipment. These factors help you pick a stacker that fits your workflow today and supports your growth tomorrow.

Business Size

Small Operations

If you run a small operation, you likely work in a space where every square foot counts. You may not move as many pallets each day, so a compact and cost-effective stacker makes sense. Smaller models fit tight aisles and help you save on energy costs. You can focus on basic features that keep your operation simple and safe.

Compact stackers work well in limited spaces.

Lower lifting capacities match lighter daily loads.

Cost-effective models help you stay within budget.

Tip: Think about your future. If you plan to expand, choose a stacker that can handle a bit more than your current needs.

Large Operations

Larger operations often need more powerful equipment. You may move hundreds of pallets daily or work in a facility with high racking systems. In this case, you should look for stackers with higher lifting capacities and advanced safety features. These models help you keep up with demand and protect your team.

High-capacity stackers handle heavy loads and tall racks.

Advanced features improve efficiency and safety.

Durable designs support long-term, intensive use.

Budget also plays a role. Larger businesses may invest more in technology that boosts productivity and reduces downtime.

Load Types

Container Weight

The weight of your typical load affects which stacker you need. If you move heavy containers, you must choose a model with a higher load capacity. Overloading a stacker can lead to accidents and equipment damage. Always check the maximum weight your operation handles before you buy.

Product Dimensions

Product size matters, too. Long or bulky items need stackers with adjustable forks or special attachments. If your operation deals with a variety of product shapes, flexibility becomes important. Some stackers, like those from TONA-TEC, offer customization options to fit different load types.

Load Type | Recommended Feature |

|---|---|

Heavy containers | High load capacity |

Bulky products | Adjustable forks/attachments |

Mixed loads | Flexible, customizable design |

Usage Frequency

Shift Patterns

How often you use your stacker affects your choice. If your operation runs one shift per day, a standard battery may be enough. For multiple shifts, you need a stacker with a long-lasting battery or quick charging options. This keeps your operation moving without delays.

Peak Periods

Some businesses have busy seasons or daily rush hours. If your operation faces peak periods, you need equipment that can handle extra demand. Look for stackers with fast charging and reliable performance. Planning for these times helps you avoid slowdowns and keeps your workflow smooth.

Note: Always consider your future needs. Choosing a flexible stacker now can save you time and money as your operation grows.

Types of Electric Stackers

When you explore the types of electric stackers, you will notice key differences in design, operator comfort, and application. Understanding these differences helps you choose the best fit for your warehouse or distribution center.

Stand-On Stackers

Stand-on stackers let you operate the machine while standing. You control the stacker using a joystick or buttons. These models work well in small warehouses and retail environments. TONA-TEC offers stand-on stackers designed for tight spaces and quick operations.

Pros and Cons

Feature | Stand-on Stackers | Sit-down Stackers |

|---|---|---|

Operating Method | Operator stands and uses joystick/buttons for control | Operator sits while controlling the vehicle |

Application Scenarios | Ideal for small warehouses and retail environments | Suitable for larger warehouses and distribution centers |

Efficiency and Flexibility | High maneuverability in tight spaces, quick operations | Better comfort for long-term use, less flexible in narrow spaces |

Training Requirements | Easier for beginners, quick to learn | Requires more comprehensive training for safety and maintenance |

Stand-on stackers allow you to turn your head easily, which reduces strain during direction changes.

You can dismount quickly, making these stackers ideal for operations with frequent stops.

These models promote better ergonomics in high-frequency tasks.

However, you may feel more fatigue during long shifts compared to sit-down models.

Tip: Choose a stand-on stacker if your warehouse has narrow aisles and you need fast, flexible movement.

Sit-Down Stackers

Sit-down stackers let you operate the machine from a seated position. TONA-TEC sit-down models provide comfort for long shifts and work well in larger facilities.

Pros and Cons

Feature | Stand-Up Stackers | Sit-Down Stackers |

|---|---|---|

Operator Position | Standing, allows for quick dismounts | Sitting, more comfortable for long durations |

Direction Changes | Easier, reduces strain with head movement | More cumbersome due to seatbelt and dismount process |

Productivity | Higher in operations with frequent direction changes | Higher for long travel distances |

Operator Fatigue | Lower in high-frequency operations | Lower in long-distance operations |

Sit-down stackers offer more comfort for extended use.

You benefit from reduced fatigue during long travel distances.

These models suit large warehouses with wide aisles.

You may need more training to operate sit-down stackers safely.

Note: Select a sit-down stacker if your operation involves long travel distances and fewer direction changes.

Electric Reachstacker Models

Electric reachstackers combine advanced technology with high performance. TONA-TEC reachstackers feature lithium-ion batteries, automated steering, and precise lifting controls.

Key Features

Feature | Description |

|---|---|

Advanced Battery Technology | Utilizes lithium-ion batteries for longer lifespan and quick recharging, enhancing productivity. |

Sophisticated Automation | Includes automated steering and precise lifting controls for improved accuracy and reduced manual effort. |

Enhanced Energy Efficiency | Designed to minimize energy consumption, lowering operational costs and carbon footprint. |

You gain longer operating hours and faster charging with lithium-ion batteries. Automated controls help you lift and move loads with greater accuracy. Energy-efficient designs lower your costs and support eco-friendly operations.

Customization

Customization options let you tailor electric reachstackers to your specific needs.

You can add telematics and remote diagnostics for real-time monitoring and predictive maintenance.

Modular designs and adjustable configurations increase flexibility across different industries.

Callout: TONA-TEC electric reachstackers offer modular designs and smart technology. You can customize features to match your workflow and improve long-term value.

By understanding the types of electric stackers and their unique benefits, you can select the right equipment for your business.

Choose the Right Electric Stacker

Decision Criteria

Needs Assessment

You need to start by understanding your business requirements. Look at your daily operations and ask yourself what you expect from your electric stacker. Consider the size of your warehouse, the weight and type of goods you move, and the number of shifts you run. If you want to boost productivity, you must match your equipment to your workflow.

Think about these questions:

What is the heaviest load you need to lift?

How high do you need to stack your goods?

Do you have narrow aisles or wide open spaces?

How often will you use the stacker each day?

A clear needs assessment helps you avoid buying a machine that is too small or too large for your operation. You also protect your investment and keep your team safe.

Feature Comparison

When you compare electric reach stackers, focus on the features that matter most for your business. Use the table below to see which criteria you should prioritize:

Criteria | Description |

|---|---|

Lifting Capacity | The maximum weight the machine can handle safely. This is crucial for operational efficiency in port settings. |

Reach | The horizontal and vertical extension capabilities for stacking and placing containers. |

Safety Features | Includes advanced load sensing systems, operator visibility enhancements, and stability control systems. |

Brand Reputation | The reliability and after-sales support from manufacturers like Kalmar, Konecranes, and Hyster. |

You should always check the lifting capacity and reach first. These features affect how much you can move and how high you can stack. Safety features protect your team and your goods. Brand reputation gives you confidence in long-term support and service.

Tip: Compare models from trusted brands like TONA-TEC. Look for advanced safety systems and strong after-sales support.

Checklist

Step-by-Step Guide

A structured checklist helps you make smart decisions when you choose the right electric stacker. Follow these steps to match your equipment to your needs and maximize productivity:

Identify the physical nature of goods you need to lift and move.

Check the type of pallets you use for palletized goods.

Measure the height of pallet racking beams, shelf heights, and loading vehicle heights.

Estimate how often you will operate the stacker each day.

Calculate the stacker traveling distance and note any gradients.

Inspect the type of floor where the stacker will operate.

Assess exposure to physical perils such as wet surfaces, corrosive elements, or extreme weather.

Evaluate the stacker operating knowledge of your workers.

Note any height and width restrictions, including doorways and overhead obstructions.

Confirm the provision for charging socket points nearby to charge the battery.

Review your budget and set a realistic spending limit.

Callout: A checklist keeps you organized and helps you avoid missing important details. You improve safety and efficiency by following each step.

Final Review

Before you make your final decision, review your checklist and compare your top choices. Ask yourself if each stacker meets your needs for safety, efficiency, and eco-friendliness. Make sure the model supports your current workflow and allows for future growth.

If you want to increase productivity, select a stacker with advanced battery technology and ergonomic controls. Look for models that offer quick charging and easy maintenance. Always choose the right electric stacker for your business size and operational goals.

Note: Consult with your supplier and request a demonstration. Test the stacker in your own warehouse to see how it performs in real conditions.

Electric Reachstacker Efficiency

Ergonomics

Operator Comfort

Operator comfort plays a big role in how well you can use a reachstacker during long shifts. Modern reachstackers include ergonomic features that help reduce fatigue and lower the risk of injury. You should look for models with easy entry steps, supportive seats, and controls that are close to your hands. These features make it easier to get in and out of the machine and help you stay focused on your work.

Ergonomic Feature | Description |

|---|---|

Forklift Operator Steps | Optimized entry/exit steps reduce slip and fall injuries. |

Forklift Cabin Handles | Handles assist with entry/exit, reducing strain on knees and ankles. |

Rear Handle Horn | Reduces strain when driving in reverse and minimizes risk of pinched fingers. |

Forklift Operator Seat | Designed for comfort with side bolsters and armrests, reducing fatigue and distraction. |

Mini Lever and Joystick Controls | Controls positioned closer to the operator to reduce strain from reaching. |

A comfortable reachstacker helps you work longer and safer. You can avoid common injuries and stay productive throughout your shift.

Visibility

Good visibility is key for safe and efficient warehouse operations. When you use a reachstacker, you need to see clearly around racks and through narrow aisles. Improved visibility helps you avoid accidents and makes it easier to move goods quickly.

Improved visibility is crucial for ensuring safety and efficiency in the workplace.

Visibility can be compromised by narrow aisles, tall racks, and poor lighting conditions.

Clear sightlines reduce the risk of collisions and accidents.

You should also make sure you receive proper training and perform pre-operational checks. These habits build a culture of safety and help everyone work more efficiently.

Maintenance

Routine Care

Regular maintenance keeps your reachstacker running smoothly and extends its life. You should follow a schedule for checking and replacing key parts. This helps you catch problems early and avoid costly breakdowns.

Maintenance Task | Recommended Action |

|---|---|

Engine Oil and Oil Filter | Replace periodically to ensure effective lubrication and cooling. |

Hydraulic Oil and Hydraulic Filter | Clean hydraulic fluid is vital; replace contaminated oil to prevent damage. |

Fuel Filter and Air Filter | Keep clean to optimize power and fuel consumption. |

Coolant | Check level and quality; replace to prevent corrosion and overheating. |

Lubrication | Regularly apply grease to moving parts to reduce friction and wear. |

Electrical System | Inspect battery terminals and wiring for corrosion and secure connections. |

Braking System | Check brake pad wear and fluid levels for safe operation. |

Regular inspections help you spot issues before they become serious.

Always follow the manufacturer's guidelines for maintenance.

Routine care reduces downtime and increases the lifespan of your reachstacker.

Spare Parts

The availability of spare parts affects how quickly you can repair your reachstacker. When you can get genuine parts easily, you spend less time waiting for repairs. This keeps your equipment running and lowers your total cost of ownership. Using the right parts also makes your reachstacker more reliable and durable.

Eco-Friendliness

Energy Source

Choosing the right energy source for your reachstacker can lower your environmental impact. Many companies now use electric or hybrid models to meet stricter emission standards. Hybrid reachstackers combine diesel and electric power, which reduces fuel use and carbon emissions. Some models use electric motors and regenerative systems to recover energy during braking and lowering loads.

The hybrid container handler market is expanding due to the need for sustainable equipment in ports and terminals.

Manufacturers are innovating to create hybrid systems that combine diesel and electric power, significantly lowering fuel consumption and carbon emissions.

There is a growing demand for eco-friendly and energy-efficient equipment in logistics, driven by stricter emission standards.

Regulatory bodies are promoting the use of alternative energy sources, such as battery-electric and hydrogen fuel cells, which influences the development of hybrid technologies.

Fuel Efficiency

Energy-efficient reachstackers help you save money and protect the environment. Brands like Crown and Linde offer models with lithium batteries that provide long runtimes and quick charging. These reachstackers use less energy and cost less to operate over time. Hybrid models can use as little as 10 liters of fuel per hour, much less than traditional diesel machines. Regenerative systems also help by capturing energy that would otherwise be lost.

Tip: Choosing an energy-efficient reachstacker supports your sustainability goals and helps you run a more efficient warehouse.

Choosing the right electric reach stacker means looking at your business size, load capacity, safety features, and eco-friendliness. You gain real benefits when you use a checklist and practical advice:

Electric reach stackers can cut fuel costs by up to 40% and help you meet emission rules.

Smart features like automated stacking and load monitoring boost safety and efficiency.

Trusted brands such as TONA-TEC, Konecranes, and Kalmar offer reliable support and innovation.

Most buyers trust expert reviews and supplier guidance. Take time to compare options and choose a stacker that fits your needs today and tomorrow.

FAQ

What is an electric reach stacker used for?

You use an electric reach stacker to lift, move, and stack pallets or containers in warehouses. It helps you organize goods on high racks and in tight spaces. This equipment improves storage efficiency and safety in your facility.

How do I choose the right load capacity?

You should check the weight of your heaviest regular load. Pick a stacker with a capacity at least 10% higher than that. This safety margin protects your team and equipment from overload risks.

Can electric reach stackers work in narrow aisles?

Yes, many models fit narrow aisles. Measure your aisle width before you buy. Choose a stacker with a small turning radius for better maneuverability. This helps you maximize storage space and move goods safely.

What are the main applications of electric stackers?

You use electric stackers for loading, unloading, and stacking pallets in warehouses, retail stores, and manufacturing plants. They also help with order picking and moving goods in distribution centers.

How long does the battery last on a single charge?

Battery life depends on the type and your usage. Lithium-ion batteries can last a full shift or longer with opportunity charging. Lead-acid batteries may need longer charging times and might not last as long during heavy use.

Are electric reach stackers safe for operators?

Manufacturers design electric reach stackers with safety features like emergency stop buttons, load indicators, and stability controls. You should always follow safety guidelines and provide training for your operators to reduce accidents.

What is the difference between electric reach stackers and container handling trucks?

Electric reach stackers work best in warehouses for stacking pallets and smaller containers. Container handling trucks handle much larger containers, often in ports or shipping yards. You should choose based on your load size and work environment.

Do electric reach stackers require much maintenance?

You need to perform regular checks on batteries, brakes, and moving parts. Follow the manufacturer’s maintenance schedule. Quick access to spare parts helps you keep your stacker running smoothly and reduces downtime.