A walkie reach stacker helps you move and lift pallets in your warehouse with ease. This electric machine combines the lifting ability of a forklift and the compact control of a pallet truck. You use a walk behind stacker in tight spaces, where its scissor fork extension lets you reach higher shelves. Many models, like the Clark WSRX Series, lift up to 3,000 lbs and can reach heights of nearly 16 feet. In 2025, warehouses favor these stackers for their compact design and advanced maneuverability.

Key Takeaways

Walkie reach stackers combine the features of forklifts and pallet trucks, making them ideal for tight spaces.

These machines can lift up to 4,000 lbs and reach heights of nearly 16 feet, enhancing warehouse efficiency.

Electric walkie stackers operate quietly and require less maintenance than traditional forklifts, saving time and costs.

Safety features like emergency stop buttons and overload protection help prevent accidents during operation.

Proper training is essential for safe use; operators should complete a training program and follow safety guidelines.

Choosing the right walkie stacker involves assessing your warehouse needs, including lift capacity and maneuverability.

Specialized models are available for unique environments, such as cold storage or e-commerce fulfillment, ensuring optimal performance.

Brands like TONA-TEC offer reliable walkie stackers with advanced features and strong customer support.

Walkie Reach Stacker Basics

What Is a Walkie Reach Stacker

You use a walkie reach stacker to move and lift pallets in your warehouse. This machine combines the features of a forklift and a pallet truck. You operate it by walking behind and using electric controls. The compact design allows you to navigate narrow aisles and confined spaces with ease. Walkie stackers are electrically powered, making them ideal for indoor use. You do not need complex battery management systems, unlike with some electric forklifts. The electric walkie stacker helps you handle lighter loads efficiently, especially in small warehouses.

Tip: If you need a reliable walkie reach stacker, consider brands like TONA-TEC for advanced models and support.

Key Features

Walkie stackers offer several important features that improve your material handling tasks. You find a sturdy mast that uses hydraulic cylinders to extend and retract the forks. This mechanism lets you reach both vertically and horizontally. The scissor fork extension provides extra height and stability, so you can stack pallets on higher shelves without losing control.

Here is a quick overview of the main mechanisms:

Mechanism | Function |

|---|---|

Mast Mechanism | Uses hydraulic cylinders for vertical and horizontal reach |

Scissor Forks | Adds height and stability, ideal for tight spaces |

Most electric walkie stackers lift up to 4,000 lbs and reach heights up to 189 inches. You benefit from quiet operation and simple controls. The compact size means you can move through narrow aisles and tight corners. You also spend less time on maintenance because walkie stackers have fewer complex parts than forklifts.

Walkie Stackers vs. Forklifts

You may wonder how walkie stackers compare to forklifts. The main differences involve size, maneuverability, and load capacity. Walkie stackers are smaller and easier to handle in tight spaces. Forklifts are larger and better for heavy loads in big facilities.

Here is a comparison table to help you understand the differences:

Characteristic | Walkie Reach Stackers | Forklifts |

|---|---|---|

Size | Smaller | Larger |

Maneuverability | High | Moderate |

Lifting Capacity | Up to a ton | More than a ton |

Noise Levels | Lower | Higher |

Suitability | Confined spaces | Larger facilities |

You use walkie stackers for lighter loads, usually up to 3,000 lbs, and for short distances. Forklifts handle heavier loads and travel longer distances. Walkie stackers excel in stability because of their lower center of gravity. You face less risk of tipping compared to forklifts, which require more training and careful operation.

Walkie stackers are compact, so you can easily navigate narrow aisles and confined spaces.

You find them easier to operate and need less training than forklifts.

Forklifts are less maneuverable in tight spaces, making them less suitable for small warehouses.

If you work in a small warehouse or need to move pallets in tight areas, walkie stackers provide a safer and more efficient solution. Electric walkie stackers also offer quieter operation and lower maintenance costs. You can choose models from trusted brands like TONA-TEC to ensure quality and support.

How Walkie Stackers Work

Operation and Controls

You operate a walkie stacker by walking behind it and using simple electric controls. The handle lets you steer, accelerate, and brake with just your hands. Most models use push-button controls for lifting and lowering the forks. You move the machine easily on flat concrete floors, which makes it perfect for indoor warehouse use. The electric walkie stacker runs quietly and does not produce emissions, so you work in a cleaner environment.

You do not need a special license to use most walkie stackers, but you should always follow safety guidelines. The control panel often includes emergency stop buttons and speed settings. You can adjust the speed for precise movements when stacking or retrieving pallets. The compact design helps you avoid obstacles and reduces the risk of accidents in busy aisles.

Tip: Always check the battery level before starting your shift. A fully charged walkie stacker ensures smooth operation throughout the day.

Scissor Fork Extension

The scissor fork extension is a key feature that sets the walkie reach stacker apart from other equipment. This mechanism allows you to extend the forks both vertically and horizontally, so you can reach pallets stored on higher shelves or deeper racks. The extension uses a hydraulic system for smooth and stable movement.

Here is a table showing the main technical specifications of the scissor fork extension:

Specification | Detail |

|---|---|

Maximum Extension Distance | 585mm / 23” |

Load Capacity | 1.6 tons |

Maximum Lifting Height | 5m / 197” |

Fork Design | Single scissor fork |

Tilt Functions | Forward & backward tilt |

You benefit from the forward and backward tilt functions, which help you position pallets accurately. The single scissor fork design gives you stability, even when you extend the forks to their maximum reach. This feature makes the walkie reach stacker ideal for stacking in tight spaces where other machines cannot reach.

Maneuverability

Walkie stackers stand out for their excellent maneuverability. You can turn and move the machine in narrow aisles and small warehouse spaces. The compact size and pedestrian operation let you work in areas where larger forklifts or reach trucks cannot fit.

Walkie stackers are designed for pedestrian use, so you have more control in tight spaces.

The compact design makes them perfect for small warehouses with limited space.

You can use walkie stackers for low to medium-height stacking and short-distance transport.

Other equipment, such as reach trucks and stand-up rider forklifts, can also work in narrow aisles and handle heavier loads. These machines often reach greater heights and offer more versatility for different warehouse tasks. However, walkie stackers are best for lighter duties and may not handle heavy loads as well as larger forklifts.

You will find that walkie stackers help you move pallets quickly and safely in environments where space is at a premium. Their design reduces the risk of collisions and makes them easy to operate, even for new users.

Note: If you need a walkie stacker for a small warehouse, consider models from TONA-TEC. Their products offer advanced maneuverability and reliable performance.

Types of Walkie Stackers

Standard Walkie Stackers

You find standard walkie stackers in many warehouses. These machines help you transport and stack pallets quickly. You operate them by walking behind and using simple controls. Standard walkie stackers work best for moving two pallets at once and stacking them at low to mid-level heights. You use them in small storage rooms and tight aisles where larger forklifts cannot fit.

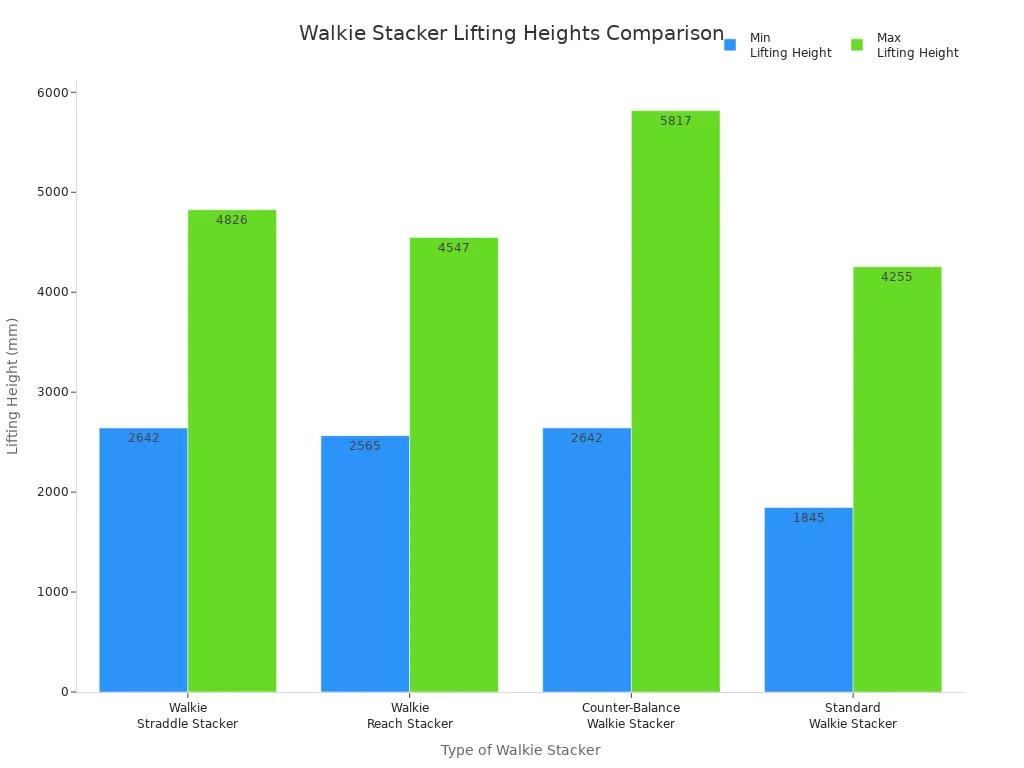

Here is a table showing common types and their primary use cases:

Type of Walkie Stacker | Primary Use Cases | Lifting Heights (mm) |

|---|---|---|

Standard Walkie Stacker | Transporting and stacking two pallets at once | 1,845 - 4,255 |

Walkie Straddle Stacker | Selective racking in small warehouses | 2,642 - 4,826 |

Loading trailers and mid-level racking | 2,565 - 4,547 | |

Counter-Balance Walkie Stacker | Lifting standard pallets in narrow aisles | 2,642 - 5,817 |

You see standard walkie stackers from brands like TONA-TEC, which offer reliable performance and easy maintenance. These stackers suit short runs and quick stacking jobs. You do not need a forklift license to operate most models, making them accessible for many warehouse workers.

Tip: Choose a standard walkie stacker if you need a simple solution for frequent pallet moves in tight spaces.

Electric Walkie Stacker

You use an electric walkie stacker for longer runs and higher lifts. These machines run on battery power, so you work in a quieter and cleaner environment. Electric walkie stackers move faster than manual models and handle both indoor and outdoor tasks. You benefit from zero emissions, which keeps your warehouse air fresh.

Here is a comparison of standard and electric walkie stackers:

Factor | Standard Walkie Stacker | Electric Walkie Stacker |

|---|---|---|

Best fit | Short runs, tight aisles, indoor | Longer runs, higher lifts, indoor/outdoor |

Noise & emissions | Can be louder; ICE units emit exhaust | Quiet, zero tailpipe (electric) |

Speed / productivity | Lower travel speed; good for short distances | Higher travel speed; better for long hauls |

You find electric walkie stackers from TONA-TEC with advanced battery systems and ergonomic controls. These models suit busy warehouses where you need to move pallets over longer distances. You also use them for stacking at greater heights, which increases your productivity.

Note: Electric walkie stackers help you reduce noise and improve air quality in your warehouse.

Straddle and Counterbalance

You choose straddle and counterbalance walkie stackers for special warehouse layouts. Straddle stackers use legs that extend around the pallet, so you handle closed-bottom and mixed pallet sizes. You maneuver these machines in tight spaces and confined areas with different pallet types.

Counterbalance walkie stackers use a weight system to balance loads. You operate them without straddle legs, which lets you lift standard pallets and odd-sized loads. These machines work well in environments with low beams or fixtures. You find them safe and reliable for handling uneven or heavy items.

Here is a table showing their advantages and suitable layouts:

Stacker Type | Advantages | Suitable Warehouse Layouts |

|---|---|---|

Straddle Stacker | Maneuvers in tight spaces, handles mixed pallet sizes | Confined areas with various pallet types |

Counterbalance Stacker | No straddle leg interference, ideal for odd-sized loads | Areas with low beams or fixtures |

Counterbalance stackers manage loads with precision, similar to forklifts.

You use them in warehouses where space is limited and pallet sizes vary.

You see TONA-TEC offering both straddle and counterbalance models designed for modern warehouse needs. These stackers help you optimize space and improve safety during daily operations.

Tip: Select a counterbalance walkie stacker if you need to lift odd-sized pallets in areas with obstacles.

Specialized Models

You may face unique challenges in your warehouse that standard walkie stackers cannot solve. Specialized models help you handle these situations with greater efficiency and safety. These walkie stacker types include features designed for specific industries, environments, or tasks. You can find models built for cold storage, high-speed operations, or tight retail backrooms.

Specialized walkie stackers often come with advanced controls, reinforced frames, or custom fork designs. Some models work best in cold storage, where low temperatures can affect battery life and machine performance. Others focus on speed and support for busy loading docks or e-commerce fulfillment centers. You can choose a walkie stacker with features like corrosion-resistant coatings, rapid charging batteries, or ergonomic handles for long shifts.

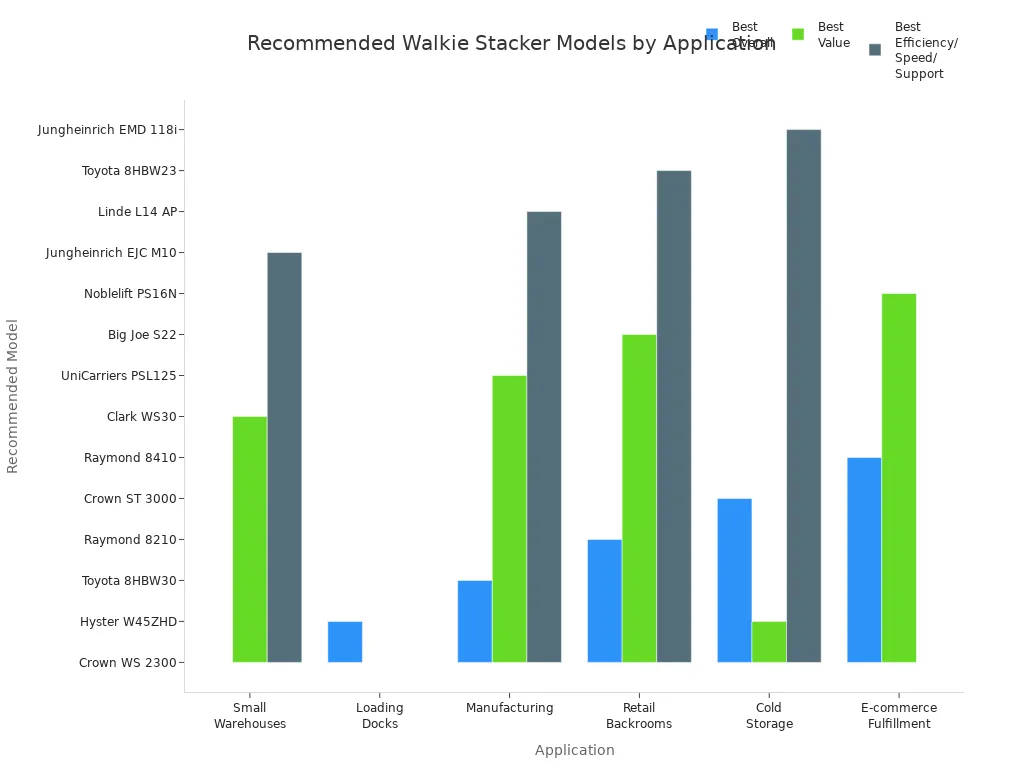

Here is a table that highlights the best specialized walkie stacker models for different applications:

Application | Best Overall | Best Value | Best Efficiency/Speed/Support |

|---|---|---|---|

Small Warehouses | Crown WS 2300 | Clark WS30 | Jungheinrich EJC M10 |

Loading Docks | Hyster W45ZHD | N/A | Crown WS 2300 |

Manufacturing | Toyota 8HBW30 | UniCarriers PSL125 | Linde L14 AP |

Retail Backrooms | Raymond 8210 | Big Joe S22 | Toyota 8HBW23 |

Cold Storage | Crown ST 3000 | Hyster W45ZHD | Jungheinrich EMD 118i |

E-commerce Fulfillment | Raymond 8410 | Noblelift PS16N | Crown WS 2300 |

You can see that each application has a model that stands out for overall performance, value, or efficiency. For example, the Crown WS 2300 works well in both small warehouses and loading docks. The Jungheinrich EJC M10 offers excellent support in small spaces. If you work in cold storage, the Crown ST 3000 and Jungheinrich EMD 118i provide reliable operation in freezing conditions.

You should consider your warehouse environment and daily tasks before choosing a specialized walkie stacker. If you need a model for e-commerce fulfillment, the Raymond 8410 and Crown WS 2300 deliver high speed and support. For retail backrooms, the Big Joe S22 gives you great value, while the Toyota 8HBW23 focuses on efficiency.

Note: TONA-TEC offers a range of specialized walkie stackers designed for modern warehouses. You can explore their products to find models that match your unique needs and benefit from expert support.

Specialized walkie stackers help you solve problems that standard forklifts or basic walkie stackers cannot address. You gain better performance, safety, and productivity by choosing the right model for your application.

Pros and Cons

Advantages

When you use a walkie stacker in your warehouse, you gain several important benefits. The compact size lets you move easily through narrow aisles and tight corners. You can operate the machine with simple electric controls, which means you do not need advanced training. The electric power system keeps your workspace quiet and free from emissions. You also spend less on maintenance because there are fewer moving parts than in larger forklifts.

Here are some key advantages you will notice:

Efficiency: You can handle more pallets in less time, which boosts your productivity.

Flexibility: You can move different sizes and weights of pallets, making your warehouse operations more versatile.

Cost-effectiveness: You save money by reducing labor needs and making better use of your storage space.

High lift: You can reach shelves that are much higher than what a manual pallet jack can handle.

Easy maneuverability: You can turn and move the walkie stacker in spaces where larger machines cannot fit.

Tip: If you want a reliable and efficient walkie stacker, TONA-TEC offers models designed for modern warehouse needs.

Limitations

While walkie stackers offer many benefits, you should also consider their limitations. These machines work best on flat, smooth floors. If your warehouse has uneven surfaces or outdoor areas, you may face challenges. Walkie stackers have a lower lifting capacity than large forklifts, so you should not use them for very heavy loads.

Keep these points in mind:

You need clear pathways to avoid accidents, especially in busy warehouses.

You must watch the load height to prevent instability when stacking.

Proper training is important for safe operation and load management.

Walkie stackers are not ideal for rough terrain or outdoor use.

Note: Always check your warehouse layout and load requirements before choosing a walkie stacker.

Walkie Stacker Forklifts vs. Others

When you compare walkie stacker forklifts to other material handling equipment, you see clear differences in cost, capacity, and space efficiency. The table below highlights how walkie stacker forklifts stack up against traditional sit-down forklifts:

Feature | Walkie Stacker Forklifts | Traditional Sit-Down Forklifts |

|---|---|---|

Upfront Cost | Lower | Higher |

Operating Cost | Cheaper | More Expensive |

Maintenance Cost | Lower | Higher |

Ideal Load Capacity | Light-to-Medium | Heavy |

Space Efficiency | High | Low |

Operator Certification Requirement | None | Required |

Battery Type | Lithium-Ion | Conventional |

Productivity | Higher due to less downtime | Lower due to maintenance needs |

You will find that walkie stacker forklifts are a smart choice for small warehouses and businesses that want to save money and space. Forklifts handle heavier loads and work better in large facilities, but they cost more and need special operator certification. Walkie stackers give you more flexibility and lower costs, making them ideal for many modern warehouse operations.

Applications in 2025

Industries and Environments

You will see walkie stackers used in many industries in 2025. These machines help you move goods in small warehouses, retail stores, logistics centers, and manufacturing plants. The reach stacker market is growing fast, especially in logistics and container handling. Ports and terminals now rely on these machines to speed up loading and unloading. The expansion of port infrastructure and the modernization of logistics operations drive this growth. As international trade increases, you need better equipment to handle more imports and exports. The global market for reach stackers is expected to rise from $3.4 billion in 2025 to $5.2 billion by 2035. This shows strong demand in industrial applications, especially in logistics.

Small warehouses use walkie stackers for quick pallet moves.

Retail stores rely on them for stocking shelves and backroom organization.

Logistics centers need them for fast order picking and shipping.

Manufacturing plants use them to move materials between workstations.

Note: You can find advanced walkie stacker forklifts from TONA-TEC that fit many of these environments.

Trends in Warehousing

Warehousing is changing quickly. The growth of e-commerce means you need to move goods faster and more efficiently. You see more warehouses using automation and electric machines. Walkie stackers now come with better batteries, smart sensors, and telemetry systems. These features help you lift, stack, and transport goods safely and efficiently. Many companies now choose electric walkie stackers with lithium-ion batteries. These models are eco-friendly and cost less to operate. You also see more warehouses using technology to track and manage inventory. This helps you save time and reduce mistakes.

Recent trends include:

Expansion of e-commerce and new distribution centers

Shift to electric models for lower emissions and costs

Use of smart sensors and telemetry for safety and efficiency

Focus on sustainability and meeting new regulations

Tip: Choosing a walkie stacker with advanced features can help you keep up with these trends.

Real-World Uses

You can see the impact of walkie stackers in real workplaces. In logistics, ports and terminals use these machines to speed up loading and unloading. One major port reported a 20% increase in container throughput after adding advanced heavy stackers. Distribution centers use walkie stacker forklifts to boost efficiency and cut labor costs. For example, a center that switched to walkie rider pallet jacks saw higher throughput and smoother operations. In manufacturing, you use walkie stackers to move materials quickly between production lines, which keeps your workflow steady.

Here are some practical examples:

Ports use walkie stackers to handle more containers in less time.

Distribution centers improve order picking and shipping speed.

Manufacturing plants keep production lines moving with fast material transport.

You can choose models from TONA-TEC to match your specific needs and get expert support for your warehouse.

Safety and Training

Safety Features

You need to know the safety features that protect you when using walkie stackers. Modern walkie reach stackers in 2025 come with advanced systems to keep you safe during every shift. Here is a table showing the most common safety features and what they do:

Safety Feature | Description |

|---|---|

Emergency Stop Button | Lets you stop the machine quickly in an emergency to prevent accidents. |

Overload Protection | Stops you from lifting loads that are too heavy, which helps avoid damage and injuries. |

Automatic Braking System | Applies brakes when you are not using the stacker, so it does not roll away, even on slopes. |

Visibility Enhancements | Uses LED lights, mirrors, and cameras to help you see better and avoid blind spots. |

Operator Training and Certification | Makes sure you know how to use the stacker safely and what to do in emergencies. |

You should always check these features before you start your shift. If you notice a problem, report it right away. These systems work together to reduce risks and help you stay safe.

Tip: Choose walkie stacker forklifts with strong safety features from trusted brands like TONA-TEC for extra peace of mind.

Operator Training

Proper training helps you use walkie stackers safely and confidently. You must complete a training program that covers both classroom learning and hands-on practice. This training teaches you how to operate the machine, spot hazards, and follow safe procedures.

Here is a simple step-by-step guide to becoming a certified operator:

Enroll in a training program that meets OSHA standards.

Complete self-paced lessons and evaluations.

Practice using the stacker under supervision until you show safe handling.

Pass a written test and a hands-on skills assessment.

You also need to keep your certification up to date. Certification must be renewed every three years. Your employer should keep records of your training and check your skills regularly. You may need refresher courses or retesting to stay current.

Note: Training records must include details about your training, assessment, and identification. Regular monitoring keeps everyone safe.

Maintenance Tips

Good maintenance keeps your walkie stacker running smoothly and safely. You should inspect the battery often for damage, corrosion, or leaks. Clean the stacker to stop dirt from building up. Lubricate moving parts to cut down on friction and wear. Always store the stacker in a dry, clean place to prevent rust.

You should also:

Check brake pads, cables, and the automatic braking system for wear.

Inspect tires for damage and make sure they are properly inflated.

Test the control system and all safety features before each use.

Following these steps helps you avoid breakdowns and accidents. If you spot any issues, fix them before using the stacker again.

Tip: Regular maintenance and inspections help you get the most out of your equipment and keep your workplace safe.

Choosing a Walkie Stacker

Assessing Needs

You need to start by understanding your warehouse requirements before choosing a walkie stacker. Look at your daily operations and ask yourself what tasks you perform most often. Do you move heavy pallets or stack items on high shelves? Do you work in narrow aisles or open spaces? These questions help you decide which features matter most.

Here is a table that shows important factors to consider:

Factor | Description |

|---|---|

Lift Capacity | Choose a model with a capacity that comfortably exceeds your heaviest pallet loads. |

Lifting Height | Consider the heights of your racking systems to ensure the stacker can reach all storage locations. |

Maneuverability | Evaluate your aisle widths and how much space you have for maneuvering the stacker. |

Battery Life | Opt for a battery capacity that can last a full work shift, as battery life can vary depending on usage. |

You should measure your aisle widths and check the height of your racks. If you have long shifts, pick a stacker with a battery that lasts all day. Think about how often you need to move pallets and how high you need to lift them.

Tip: Write down your warehouse’s key measurements and daily tasks. This list will help you match your needs to the right stacker model.

Selection Criteria

Once you know your needs, you can focus on the most important criteria for choosing a walkie reach stacker. Use this checklist to guide your decision:

Capacity and Lift Height: Check the maximum weight and stacking height you need.

Application and Industry Requirements: Match the stacker to your specific cargo and industry.

Fuel Type and Emissions: Decide between electric or diesel based on your environment.

Maneuverability and Turning Radius: Make sure the stacker can turn easily in your space.

Maintenance and Serviceability: Pick models that are easy to maintain and have good spare parts support.

Safety Features: Look for strong safety systems to protect you and your goods.

Cost and Budget Considerations: Compare upfront costs and long-term savings.

Availability of Spare Parts: Ensure you can get replacement parts quickly.

Operator Comfort and Ergonomics: Choose a stacker with comfortable controls and design.

You should prioritize safety and comfort. A stacker with good ergonomics helps you work longer without fatigue. Electric models offer quiet operation and lower emissions, which improve your work environment.

Note: Always check if the stacker meets your industry’s safety standards and regulations.

Brand Comparison

You want a walkie stacker that delivers reliability and support. TONA-TEC offers a wide range of models designed for different warehouse needs. Their products feature advanced safety systems, strong battery life, and easy maintenance. You can find stackers with high lift capacities and compact designs for tight spaces.

Compare brands by looking at:

Product range and model options

Warranty and after-sales support

Availability of spare parts

Customer reviews and reputation

TONA-TEC stands out for its quality and customer service. You can explore their products at TONA-TEC’s official site to find models that fit your requirements.

�� If you want expert advice and reliable equipment, consider TONA-TEC for your next walkie stacker purchase. Their team can help you choose the best model for your warehouse and budget.

Budget matters too. Look at the total cost of ownership, including maintenance, energy use, and spare parts. A higher upfront investment in a quality stacker often saves you money over time.

Walkie reach stackers help you improve efficiency and safety in your warehouse. You should match equipment to your needs by considering lifting capacity, power source, and ergonomic features:

Consideration | Description |

|---|---|

Lifting Capacity | Choose a model that can handle the typical loads and heights required in your warehouse. |

Power Source | Electric models are preferred for maintenance and environmental reasons; check battery life. |

Ergonomic Features | Look for adjustable handles and easy-to-reach controls to enhance operator comfort and safety. |

Safety matters every day.

Proper training for operators is essential.

Regular refresher training prevents complacency.

Operators must stay aware and follow speed limits.

Pre-operational checks keep equipment safe.

Correct load handling prevents accidents.

Safety reminder: Make training a priority for every new operator. It’s the best way to protect your team and your investment.

You can explore reliable models and expert support at TONA-TEC. Research your options or contact suppliers to find the best fit for your warehouse.

FAQ

What is the main difference between a walkie reach stacker and a forklift?

You use a walkie reach stacker for lighter loads and tight spaces. Forklifts handle heavier loads and work better in large areas. Walkie reach stackers offer easier controls and lower maintenance.

Can you operate a walkie reach stacker without a forklift license?

You do not need a forklift license for most walkie reach stackers. You should complete safety training before using one. Always follow your workplace rules and local regulations.

How long does the battery last on a walkie reach stacker?

You get up to 8 hours of use on a full charge with most electric models. Battery life depends on usage and model. TONA-TEC offers stackers with advanced lithium-ion batteries for longer shifts.

What types of pallets can you move with a walkie reach stacker?

You move standard and mixed-size pallets. Straddle models handle closed-bottom pallets. Counterbalance stackers lift odd-sized loads. Check your stacker’s specifications for pallet compatibility.

Is a walkie reach stacker safe for use in cold storage?

You can use specialized walkie reach stackers in cold storage. Choose models with reinforced frames and batteries designed for low temperatures. TONA-TEC provides options for cold environments.

How often should you inspect and maintain your walkie reach stacker?

You should inspect your stacker daily before each shift. Schedule regular maintenance every month. Clean and lubricate moving parts often. Follow the manufacturer’s guidelines for best results.

What is the typical lifting capacity of a walkie reach stacker?

You can lift up to 4,000 lbs with most models. Always check your stacker’s rating before moving heavy loads. TONA-TEC offers models with various capacities to fit your needs.

Where can you buy reliable walkie reach stackers?

You find reliable walkie reach stackers at TONA-TEC. Their products offer strong safety features, long battery life, and expert support for your warehouse.