Introduction

Understanding the life expectancy of a reach stacker is crucial for businesses that rely on material handling equipment. A reach stacker’s lifespan impacts operational efficiency, maintenance costs, and equipment planning.

In this article, we will explore the key factors that influence its life expectancy and how businesses can extend its useful life. By the end, you’ll understand how to make informed decisions about maintenance, replacement, and maximizing fleet efficiency.

Key Factors Influencing the Life Expectancy of a Reach Stacker

Frequency of Use

The more frequently a reach stacker is used, the faster its components will wear down. In high-demand operations where the reach stacker is used for multiple shifts daily, the wear and tear on the engine, hydraulic systems, and lifting mechanisms will accelerate. For instance, stackers operating in large ports or busy distribution centers will generally have a shorter lifespan compared to those used in less intense, lower-traffic environments.

Proper maintenance can help extend the life of the reach stacker, but regular and intense use will always place a strain on critical parts, leading to earlier deterioration of these components.

Operating Environment

The environment where the reach stacker operates can significantly impact its lifespan. Machines exposed to extreme conditions, such as intense heat, high humidity, or corrosive environments (e.g., saltwater in coastal areas), may experience faster wear and corrosion of their parts. For example, reach stackers used in cold storage facilities or in outdoor operations with high dust levels may suffer from issues such as battery degradation, compromised engine performance, and hydraulic malfunctions.

Indoor operations in clean, controlled environments generally lead to longer equipment lifespans. Proper storage and cleaning routines can mitigate some of the effects of harsh environments, extending the reach stacker’s useful life.

Factor | Impact on Life Expectancy |

Frequency of Use | Heavy use shortens lifespan; less frequent use extends it. |

Operating Environment | Harsh conditions like extreme temperatures and humidity decrease lifespan. |

Maintenance Practices | Regular servicing and repairs increase lifespan; neglect leads to breakdowns. |

Technological Upgrades | Upgrades like energy-efficient motors can extend life. |

Maintenance Practices

Regular and proactive maintenance is one of the most effective ways to extend the reach stacker’s lifespan. Routine maintenance tasks, such as checking fluid levels, lubricating moving parts, inspecting tires, and replacing worn-out components, help avoid more costly repairs down the line. Neglecting maintenance can lead to component failures, which may shorten the life of the reach stacker and increase downtime.

In contrast, businesses that follow a strict maintenance schedule can maximize the lifespan of their reach stackers, ensuring that each machine performs optimally for as long as possible.

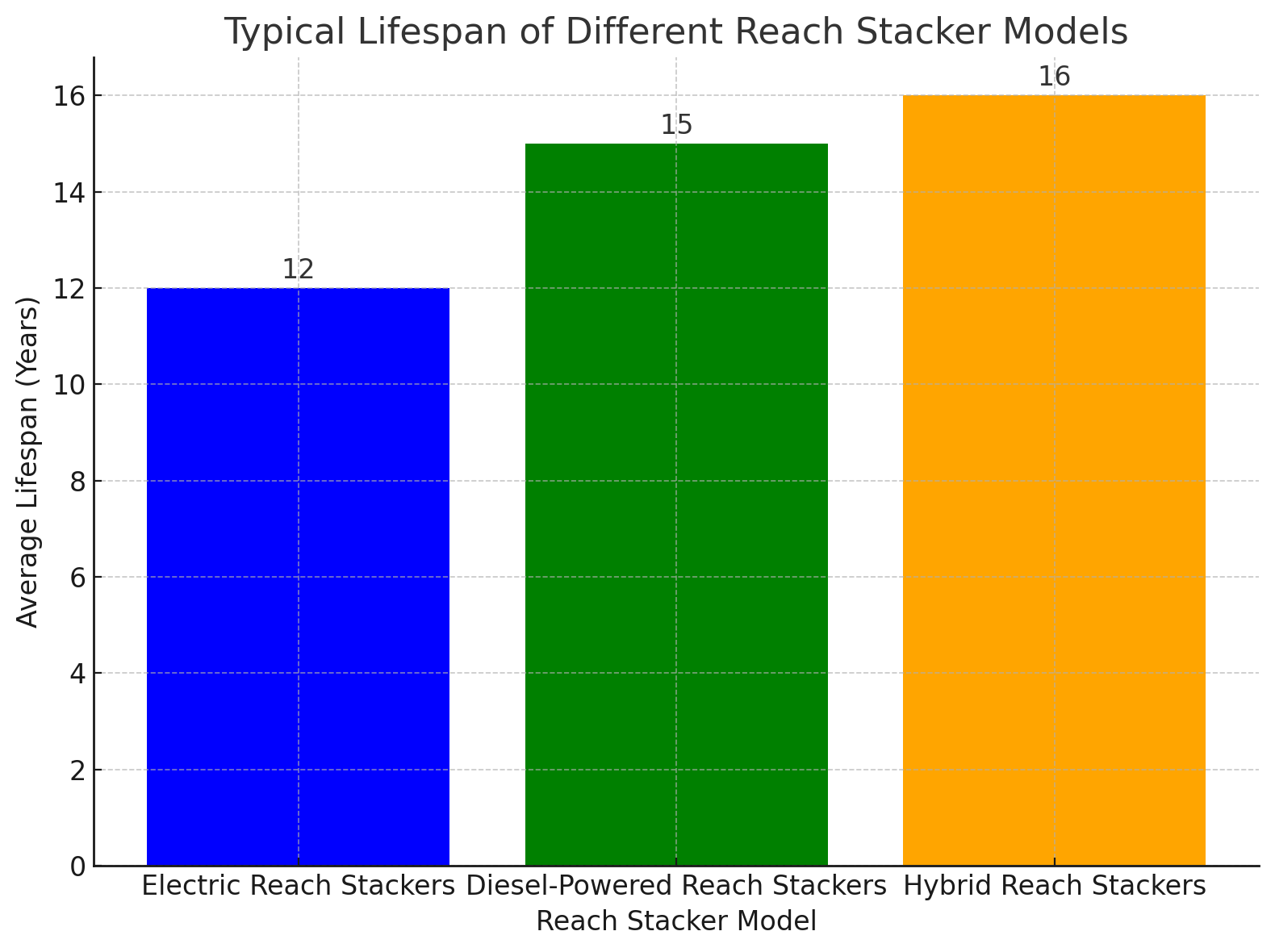

Typical Life Expectancy of Different Reach Stacker Models

Electric Reach Stackers

Electric reach stackers typically have a lifespan of 8-15 years, depending on factors such as battery quality, frequency of use, and operating conditions. One of the advantages of electric models is their reduced fuel consumption and lower maintenance requirements compared to diesel-powered counterparts. However, battery degradation is a challenge, and replacing batteries may become a significant cost as the stacker ages.

To maximize the lifespan of an electric reach stacker, businesses should invest in high-quality batteries and follow the manufacturer’s recommendations for battery maintenance and charging practices.

Diesel-Powered Reach Stackers

Diesel-powered reach stackers are built to last between 10-20 years, especially in demanding outdoor environments. These machines are highly durable and designed to withstand tough conditions, such as rough terrain and heavy lifting. However, diesel engines require more frequent servicing than electric models, particularly regarding fuel systems, exhaust components, and engine maintenance.

Proper care and regular servicing can extend the life of a diesel-powered reach stacker significantly, but businesses should be prepared for higher maintenance costs compared to electric options.

Model Type | Typical Lifespan (Years) | Key Features Impacting Lifespan |

Electric Reach Stackers | 8-15 | Battery quality and management, less maintenance required |

Diesel-Powered Reach Stackers | 10-20 | Robustness for outdoor conditions, requires more frequent maintenance |

Hybrid Reach Stackers | 12-18 | Balance between fuel efficiency and performance, mixed maintenance needs |

Hybrid Reach Stackers

Hybrid reach stackers combine the best of both electric and diesel power, offering fuel efficiency with robust lifting capacity. These models typically last between 12-18 years. Hybrid machines are ideal for businesses looking to balance power with fuel savings. They have the advantage of offering lower emissions and better fuel consumption rates, but maintaining both engine types can require more attention to detail.

Hybrid reach stackers offer a great solution for businesses aiming to reduce their environmental impact while still benefiting from high performance in heavy-duty tasks.

How to Extend the Life of Your Reach Stacker

Preventive Maintenance Practices

Maintaining your reach stacker through regular inspections is crucial for its longevity. Routine checks on hydraulic systems, fluid levels, and tires can prevent minor issues from escalating into major repairs. Following the manufacturer’s recommended maintenance schedule ensures that all parts are functioning properly, extending the stacker’s useful life.

It’s important to address potential issues before they become significant problems. For example, checking for leaks in the hydraulic system can prevent a major breakdown.

Operator Training

Proper training of reach stacker operators can reduce the chances of wear and tear caused by improper use. Operators should be trained to follow best practices, including smooth operation, safe handling of loads, and avoidance of overloading. Misuse, such as over-acceleration, heavy braking, and rough handling, can drastically reduce the stacker’s lifespan.

A well-trained operator ensures the stacker operates efficiently and with minimal strain on its components.

Upgrading Components

Replacing worn-out parts before they fail is another way to extend the life of a reach stacker. For example, proactively upgrading the hydraulic system, batteries, or lifting masts can prevent unexpected failures and improve overall performance. Additionally, staying updated with new technologies and upgrading components to more energy-efficient versions can help reduce wear on the machine while also improving operational efficiency.

Common Signs that Your Reach Stacker is Reaching the End of Its Useful Life

Declining Performance

If a reach stacker begins to show signs of sluggish performance, such as slow lifting speeds or difficulty handling loads, it may indicate that the machine is nearing the end of its useful life. Other signs include a drop in fuel efficiency, which could suggest that the engine or power system is no longer operating at peak efficiency.

Rising Maintenance Costs

As a reach stacker ages, the frequency and cost of repairs may increase. If maintenance costs begin to outweigh the value of keeping the machine in service, it may be time to consider replacement. Business owners should perform a cost-benefit analysis to determine when it’s no longer cost-effective to continue maintaining the machine.

Excessive Wear on Key Components

Over time, key components of a reach stacker such as the engine, hydraulics, and lifting masts will wear out. If cracks, leaks, or other forms of excessive wear become apparent, it may indicate that the machine’s lifespan is coming to an end. Monitoring the condition of these critical components will help businesses make informed decisions about whether to repair or replace the machine.

Technological Innovations and Their Impact on Reach Stacker Longevity

Telematics and Fleet Management

Modern reach stackers often come equipped with telematics and fleet management systems that monitor performance, engine hours, and component health. These systems allow businesses to track the health of their machines in real-time, ensuring timely maintenance and reducing downtime. Predictive maintenance capabilities can help businesses identify potential issues before they cause major failures, extending the life of the machine.

Automation and Smart Features

Automation features such as auto-positioning, collision avoidance, and auto-leveling help improve the operational efficiency of reach stackers. These systems not only enhance safety but also reduce wear and tear on the machine, prolonging its useful life. By automating repetitive tasks, these features help minimize the strain on operators and the equipment, contributing to a longer lifespan.

Diagnostic Tools

Integrated diagnostic tools in reach stackers can monitor key systems and alert operators and maintenance teams to potential issues. These tools provide valuable insights into the machine’s performance, enabling proactive repairs and maintenance. Customizable alerts for each machine based on its unique usage patterns help businesses stay ahead of maintenance needs, further extending the reach stacker’s life.

Evaluating When to Replace Your Reach Stacker

Economic Life vs. Useful Life

Understanding the difference between economic life and useful life is key when evaluating whether to replace a reach stacker. The useful life refers to the period when the stacker is still functional, while the economic life is when repairs and maintenance become more expensive than the value derived from the machine. Businesses should replace the stacker when the cost of repairs exceeds the benefits.

Return on Investment (ROI)

Businesses should also assess the ROI of replacing an aging reach stacker. Continuing to use an older machine may result in more frequent repairs and downtime, affecting productivity. Investing in a new stacker can improve operational efficiency and ultimately lead to higher profitability in the long run.

Factors to Consider in the Decision-Making Process

When deciding to replace a reach stacker, consider the cost of downtime, repair costs, and the impact on overall operations. If a stacker frequently breaks down or requires costly repairs, replacing it may be more economical than continuing to maintain it.

Conclusion

The life expectancy of a reach stacker is influenced by factors such as frequency of use, operating environment, maintenance practices, and technological advancements. Understanding these factors helps businesses maximize the lifespan of their reach stackers, optimize performance, and make informed decisions about maintenance and replacement. Regular maintenance, operator training, and technological upgrades are key strategies to extend the life of a reach stacker. Hunan Tona Machinery Technology Co., Ltd. offers reliable, high-performance reach stackers that provide businesses with long-term value through enhanced durability and efficiency.

FAQ

Q: What factors affect the life expectancy of a reach stacker?

A: The life expectancy of a reach stacker is influenced by factors like frequency of use, operating environment, maintenance practices, and technological upgrades.

Q: How long does a reach stacker typically last?

A: A reach stacker can last between 8-20 years, depending on usage, environment, and maintenance. Electric models tend to last 8-15 years, while diesel models can last up to 20 years.

Q: How can I extend the life of my reach stacker?

A: Regular maintenance, proper operator training, and timely upgrades to components like hydraulics and batteries can significantly extend a reach stacker's life.

Q: What is the average cost of maintaining a reach stacker?

A: The annual maintenance cost of a reach stacker typically ranges from 3% to 5% of the machine’s original purchase price.

Q: When should I replace my reach stacker?

A: Consider replacing your reach stacker when repair costs outweigh the benefits, or when it consistently experiences performance issues despite maintenance.

Related Blogs

-

Reach stackers, also known as container handlers or intermodal handlers, are essential machines in material handling and logistics. They are equipped with a telescopic boom that allows for efficient lifting and stacking of containers at various heights. While reach stacker is the most common term, alternatives like container stacker and stacking crane emphasize different functionalities. The choice of terminology often depends on regional preferences, specific applications, or the machine's capabilities. Understanding these terms helps businesses select the right equipment for their operations. Whether lifting or stacking, reach stackers optimize container handling in ports, warehouses, and rail yards.

Reach stackers, also known as container handlers or intermodal handlers, are essential machines in material handling and logistics. They are equipped with a telescopic boom that allows for efficient lifting and stacking of containers at various heights. While reach stacker is the most common term, alternatives like container stacker and stacking crane emphasize different functionalities. The choice of terminology often depends on regional preferences, specific applications, or the machine's capabilities. Understanding these terms helps businesses select the right equipment for their operations. Whether lifting or stacking, reach stackers optimize container handling in ports, warehouses, and rail yards. -

This article compares container handlers and reach stackers, two essential machines for container handling. It outlines their differences, including storage capacity, selectivity, and manoeuvrability. Container handlers excel in speed and efficiency for quick access to containers in narrow spaces, while reach stackers are ideal for maximizing storage density by stacking containers in multiple rows. The article discusses lifting capacities, cost considerations, and ROI for both machines, helping businesses choose the best option based on their specific needs. Reach stackers are recommended for operations focused on optimizing space, whereas container handlers are better for quick and efficient container movement.

This article compares container handlers and reach stackers, two essential machines for container handling. It outlines their differences, including storage capacity, selectivity, and manoeuvrability. Container handlers excel in speed and efficiency for quick access to containers in narrow spaces, while reach stackers are ideal for maximizing storage density by stacking containers in multiple rows. The article discusses lifting capacities, cost considerations, and ROI for both machines, helping businesses choose the best option based on their specific needs. Reach stackers are recommended for operations focused on optimizing space, whereas container handlers are better for quick and efficient container movement. -

Reach stackers are essential machines for handling and stacking heavy containers in ports, rail yards, warehouses, and construction sites. They improve efficiency by quickly loading, unloading, and organizing containers in tight spaces. In ports, they optimize space by stacking containers up to six high and facilitate fast transfers between ships, trucks, and railcars. In rail yards, they reduce turnaround times, while in warehouses, they handle heavy loads and work in rough terrains. Reach stackers enhance supply chain productivity, reduce downtime, and improve cargo handling. Regular maintenance and operator training are key to maximizing their benefits in logistics operations.blogs

Reach stackers are essential machines for handling and stacking heavy containers in ports, rail yards, warehouses, and construction sites. They improve efficiency by quickly loading, unloading, and organizing containers in tight spaces. In ports, they optimize space by stacking containers up to six high and facilitate fast transfers between ships, trucks, and railcars. In rail yards, they reduce turnaround times, while in warehouses, they handle heavy loads and work in rough terrains. Reach stackers enhance supply chain productivity, reduce downtime, and improve cargo handling. Regular maintenance and operator training are key to maximizing their benefits in logistics operations.blogs