Containerized Bulk Handling uses specialized containers to move bulk cargo efficiently and safely. This method relies on open-top containers and equipment like rotating spreaders to load and unload materials. Companies choose this process because it reduces dust, keeps products clean, and improves safety.

The global market for containerized bulk handling continues to grow.

Metric

Value (2024)

CAGR (2025-2032)

ISO Container Units

869.5 thousand

9.9%

Containerized Bulk Handling increases cost savings.

It shortens transit times.

It improves supply quality and supports cleaner operations.

Key Takeaways

Containerized Bulk Handling uses sealed containers to move bulk cargo safely, reducing dust, spills, and contamination.

This method speeds up loading and unloading, saving time and cutting costs for companies and ports.

Special equipment like rotating spreaders helps unload cargo quickly and with almost no product loss.

Sealed containers protect product quality by keeping goods clean, fresh, and secure during transport.

Containerized Bulk Handling lowers environmental impact by reducing waste, emissions, and pollution.

What Is Containerized Bulk Handling

Definition

Efficient Containerized Bulk Handling is a logistics process that uses sealed containers to move bulk and break bulk cargo. Companies load materials like grains, minerals, chemicals, or liquids into special containers. These containers often have open tops or removable lids. Workers seal the containers to keep the cargo safe from dust, moisture, and contamination. This method prevents product loss and keeps the environment cleaner.

Containerized Bulk Handling also includes the use of ISO Tanks or Flexitanks for liquids. ISO Tanks carry hazardous liquids, while Flexitanks suit non-hazardous products. The choice depends on the type of cargo and safety requirements. Each container has a unique code for tracking and management. This system allows companies to move goods by truck, train, or ship without opening the container until it reaches its destination.

Note: Related terms include Containerized Bulk Cargo Handling, which refers to the same process of using containers for bulk goods.

Key Features

Sealed containers protect cargo from dust, weather, and theft.

Open-top ISO containers and removable lids allow easy loading and unloading.

Specialized equipment, such as rotating spreaders and tipplers, handle containers without exposing the cargo.

The process supports dust-free transport, which helps keep the environment clean.

Containers can stack efficiently at ports, saving space and reducing the need for large storage buildings.

The system works for many types of cargo, including dry goods, liquids, and even refrigerated items.

Containerized Bulk Handling uses equipment like Rotainers, front-end loaders, and conveyors to move and unload containers quickly.

Companies can track each container with a unique identifier, improving supply chain reliability.

The method meets international safety standards, such as the International Maritime Dangerous Goods (IMDG) Code and the International Convention for the Safety of Life at Sea (SOLAS).

Industry | Usage of Containerized Bulk Handling (IBCs) | Reported Outcomes |

|---|---|---|

Chemicals | Safe transport of hazardous liquids; use of metal IBCs for durability | Compliance with safety regulations; enhanced product safety; cost-effective and eco-friendly packaging |

Food & Beverage | Bulk storage and transport with food-grade plastic and stainless steel IBCs | Largest revenue share; hygienic packaging; contamination prevention; compliance with food safety standards |

Pharmaceuticals | Hygienic and compliant packaging solutions | Support for safety regulations; improved product safety; market growth driven by packaging needs |

Manufacturing | Bulk goods transport; integration of smart technologies (RFID, monitoring) | Improved logistics efficiency; cost reduction; enhanced operational efficiency |

Petrochemicals | Transport of chemicals and oils using metal IBCs | Fastest growth segment; durability; safety compliance; environmental benefits through reusable packaging |

Containerized Bulk Handling stands out because it protects product quality, saves space, and supports fast, safe, and flexible transport. Many industries, such as chemicals, food, and manufacturing, use this method to improve efficiency and meet strict safety standards.

Traditional vs. Containerized Methods

Traditional Bulk Handling

Traditional bulk handling moves large amounts of materials like grains, minerals, or chemicals using open systems. Workers often use bulk bags, conveyors, and storage silos. The process usually follows these steps:

Workers fill bulk bags at a filling station, which controls dust and supports the bag.

They transport the filled bags using hoists or trolleys.

At the discharge station, workers remove the product while trying to control dust.

Equipment such as vibration motors or agitation devices helps empty the bags.

Safety rules require supporting bags from below to prevent accidents.

Another common method involves unloading raw materials from trucks, ships, or trains. Workers move these materials to storage yards or silos using conveyor belts. Automatic reclaimers or gravity systems help retrieve the materials for processing. Throughout the process, teams must maintain equipment and control dust to keep the operation safe.

Traditional systems face several challenges:

Spillage and blockages at transfer points.

Dust pollution and environmental contamination.

High maintenance needs for conveyors and other equipment.

Noise pollution and safety risks from heavy machinery.

Limited flexibility for handling different materials.

CBH Advantages

Containerized Bulk Handling changes the process by sealing materials in containers from the start. This method keeps cargo safe from dust, moisture, and theft. The sealed containers move easily between ships, trucks, and trains, reducing the number of transfer points. This system lowers the risk of spillage and contamination.

Key advantages include:

Sealed containers prevent dust and material loss during transport and storage.

Fewer transfer points mean less chance for spills or blockages.

Standardized containers allow for easy stacking and efficient use of space.

Specialized equipment, such as rotating spreaders and automated cranes, increases speed and safety.

Lower operational costs come from reduced handling fees and less cargo damage.

The system supports intermodal transport, making logistics more flexible.

Aspect | Containerized Shipping | Traditional Bulk Handling |

|---|---|---|

Risk and Security | Lower risk of damage and theft, more secure | Higher risk of cargo damage, contamination |

Flexibility | High, supports intermodal transport | Limited, requires dedicated bulk facilities |

Environmental Impact | Less dust and contamination | More dust, spills, and pollution |

How Containerized Bulk Handling Works

Process Steps

Containerized Bulk Handling follows a clear four-stage process. Each stage helps companies move bulk cargo safely and efficiently.

Assessment and Planning

Teams start by reviewing their current logistics. They look at transportation routes, infrastructure, and rules. This step helps them decide if containerization fits their needs and meets safety standards.Technology Integration

Companies add digital tools to their operations. They use IoT tracking, AI analytics, and cloud data systems. These tools give real-time updates on container locations and cargo conditions.Execution and Monitoring

The process begins with small pilot programs. Teams watch key numbers like transit times and cargo quality. They make changes based on the data to improve results.Training and Collaboration

Workers receive training on safe handling, loading, and unloading. Companies work closely with partners, such as suppliers and carriers, to keep the process smooth and transparent.

Teams that follow these steps see better control, higher efficiency, and safer operations in Containerized Bulk Handling.

Equipment Used

Specialized equipment makes Containerized Bulk Handling fast and reliable. Each tool plays a key role in moving and protecting bulk cargo.

Equipment Type | Function and Benefit |

|---|---|

Front-End Loaders | Scoop and load bulk materials into containers quickly. |

Conveyors | Move materials from storage areas to containers with minimal spillage. |

Rotating Spreaders | Pick up sealed containers, remove lids, and rotate containers 360° to empty cargo completely. |

Tipplers | Tilt containers to discharge materials, useful for sticky or wet cargo. |

Container Cranes | Lift and move containers between trucks, trains, and ships. |

Rotating spreaders, such as the RAM Revolver or CRS Rotainer, stand out for their speed and efficiency. These devices pick up sealed containers, remove the lids, and rotate the containers to empty all cargo. This method ensures almost no product loss, even with sticky or wet materials. For example, Eti Bakir, a mining company, switched to a rotating spreader system and cut unloading times from 15-20 minutes to under 3 minutes. This change increased their product flow and reduced costs.

Systems like TR350R Containerized Bulk Handling and TCZ400R Containerized Bulk Handling offer high-speed, efficient, and stainless steel options. These systems work with standard equipment, such as forklifts and reach-stackers, making them easy to add to existing operations. Companies can also move these systems between sites, which saves money and adds flexibility.

Loading and Unloading

Loading and unloading are critical steps in Containerized Bulk Handling. Teams follow strict safety protocols to protect workers and cargo.

Teams prepare a detailed loading plan and share it with port authorities.

They collect information about the cargo, equipment, and port conditions.

Workers follow international safety codes, such as the IMO Code of Safe Practice and SOLAS.

Cargo is trimmed to prevent shifting during transport.

Teams check the weight and balance of each container to avoid overloading.

Continuous monitoring ensures that the ship and equipment stay within safe limits.

All parties, including ship officers and stevedores, work together to handle special cargo needs.

Proper loading and unloading also require secure stowage. Workers use dunnage, nets, and chocks to keep cargo from moving. They inspect and maintain securing equipment, such as twist-locks, to prevent accidents. For refrigerated containers, teams monitor temperature and humidity at all times.

Containerized Bulk Handling speeds up loading and unloading compared to traditional methods. Container cranes can move about 30 containers per hour. This means a ship carrying 1,000 containers can be unloaded in 10 to 20 hours. In contrast, traditional bulk handling can take 70 to 100 hours for the same amount of cargo. The use of containers allows cranes to lift and move cargo as single units, making the process much faster and safer.

Benefits

Efficiency

Containerized Bulk Handling increases efficiency in many ways. Standardized containers allow for quick loading and unloading. Ports can move more cargo in less time. Companies see fewer delays and faster transit times. The use of specialized systems, such as Efficient Containerized Bulk Handling and High-Speed Containerized Bulk Handling, helps speed up operations.

Ports track performance using metrics like throughput at the quay, yard movements, and port gate activity.

Larger vessels can carry more containers, reducing the number of trips needed.

Standardized containers make stacking and storage easier, saving space and time.

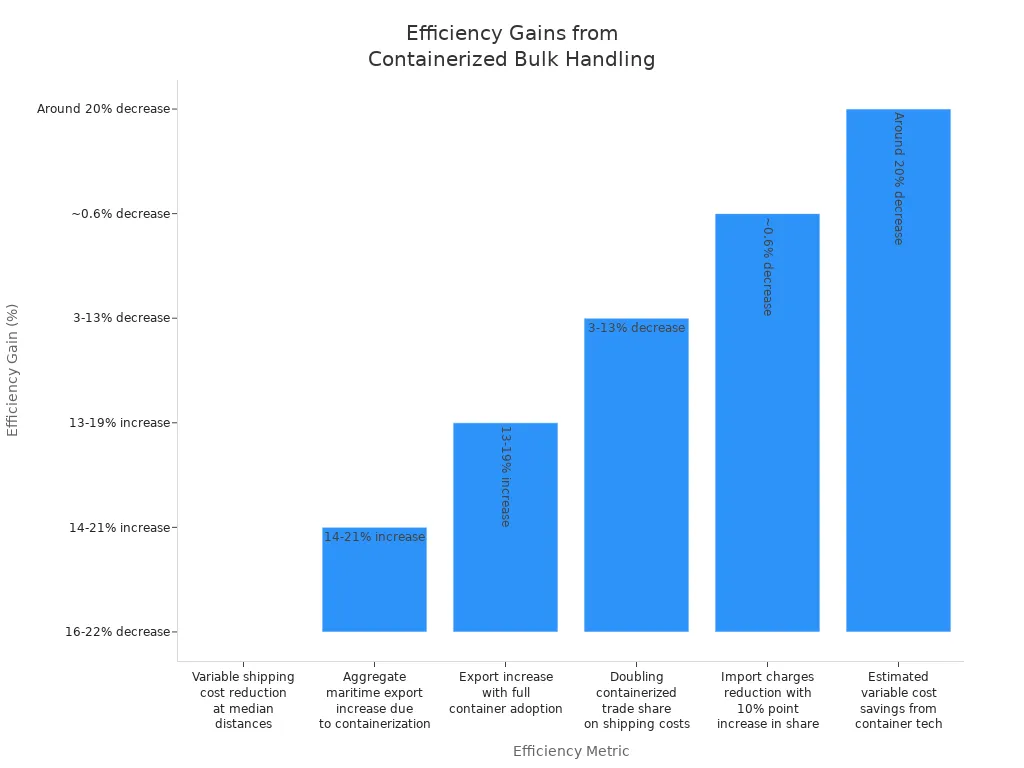

Metric | Quantitative Finding |

|---|---|

Variable shipping cost reduction at median distances (~10,400 km) | 16-22% decrease |

Aggregate maritime export increase due to containerization | 14-21% increase |

Export increase with full container adoption (Turkey and U.S.) | 13-19% increase |

Effect of doubling containerized trade share on shipping costs | 3-13% decrease |

Import charges reduction with 10% increase in containerized trade share | ~0.6% decrease |

Estimated variable cost savings from container technology | Around 20% |

Companies also save money by reducing labor and handling costs. Fewer errors and less damage mean lower insurance and replacement expenses. Optimized space use and better inventory management further cut costs.

Environmental Impact

High-Speed Containerized Bulk Handling helps protect the environment. Sealed containers prevent dust and spills during transport. This reduces contamination of air, soil, and water. Reusable containers lower packaging waste. Fewer trips are needed because containers hold more cargo, which means less fuel use and fewer emissions. Efficient handling at ports and warehouses also reduces the risk of spills and accidents.

Sealed containers keep cargo from leaking or spilling.

Reusable containers cut down on waste.

Fewer trips mean lower CO2 emissions.

Less exposure to weather protects both cargo and the environment.

Product Quality

This system keeps products safe and high in quality. Containers use liners made from materials like polyethylene to protect dry goods. Thermal liners shield cargo from temperature changes. Refrigerated containers, or reefers, keep food and other perishables fresh. Companies use blockchain and tracking tools to monitor cargo conditions. These steps help prevent spoilage and maintain product value.

Liners and thermal protection keep goods safe from contamination and temperature swings.

Specialized containers, such as Stainless Steel Containerized Bulk Handling, protect sensitive or high-value cargo.

Real-time tracking ensures the chain of integrity from origin to destination.

Security

Security improves with containerized systems. Tamper-evident seals show if someone tries to open a container. Real-time tracking with GPS and RFID helps companies know where their cargo is at all times. Ports use cameras and strict access controls to keep containers safe. Smart locks and remote monitoring add extra layers of protection. Regular inspections and compliance with international codes help prevent theft and smuggling.

Tamper-evident seals and smart locks protect cargo.

Real-time tracking and surveillance detect suspicious activity.

Strict access controls and regular inspections keep cargo secure.

Blockchain records create a tamper-proof history of each shipment.

Containerized solutions offer many advantages for bulk cargo.

Standardized containers support global transport and protect cargo from damage.

Flexible designs carry many types of goods and reduce costs.

Rapid handling speeds up shipping and improves warehouse use.

Reusable containers help the environment by cutting waste.

Smart ports now use automation, AI, and digital twins to boost safety and efficiency. The market will keep growing as ports adopt new technology and cleaner energy.

Trend | Impact |

|---|---|

Automation | Faster, safer operations |

Digitalization | Better tracking and planning |

Sustainability | Lower emissions, less waste |

FAQ

What is the main difference between traditional bulk handling and Containerized Bulk Handling?

Containerized Bulk Handling uses sealed containers to move cargo. This method keeps materials safe from dust and weather. Traditional bulk handling often leaves cargo exposed, which can lead to spills and contamination.

Which industries benefit most from Containerized Bulk Cargo Handling?

Many industries use Containerized Bulk Cargo Handling. Food, chemicals, mining, and manufacturing companies see the most benefits. They choose this method for better safety, cleaner transport, and higher product quality.

What equipment supports high-speed operations in CBH?

Systems like TR350R Containerized Bulk Handling and TCZ400R Containerized Bulk Handling use rotating spreaders and tipplers. These tools help load and unload containers quickly. Ports can move more cargo in less time.

How does CBH improve environmental safety?

Sealed containers prevent dust and spills. This keeps air and water clean. Efficient Containerized Bulk Handling and Stainless Steel Containerized Bulk Handling also reduce waste by using reusable containers.

Is CBH secure for valuable or sensitive cargo?

Yes. CBH uses tamper-evident seals and real-time tracking. These features protect cargo from theft or damage. Companies trust High-Speed Containerized Bulk Handling for safe and secure transport.

Related Blogs

-

You use a Container Rotating Spreader to lift sealed bulk containers, rotate them to the desired angle, and unload materials efficiently with minimal spillage. After unloading, you re-seal the containers for transport.Common benefits include:Improved efficiency and cost-effectivenessZero loss materi

You use a Container Rotating Spreader to lift sealed bulk containers, rotate them to the desired angle, and unload materials efficiently with minimal spillage. After unloading, you re-seal the containers for transport.Common benefits include:Improved efficiency and cost-effectivenessZero loss materi