You can boost efficiency, save money, and make your port operations more reliable by optimizing containerized bulk handling. Innovations like efficient containerized bulk handling, high-speed containerized bulk handling, and stainless steel containerized bulk handling have changed how you move bulk cargo. Many ports now use containerized bulk handling instead of older methods. This shift helps you handle cargo faster and with less damage.

Key Takeaways

Containerized bulk handling speeds up port operations by using sealed containers and machines, reducing wait times and manual work.

This method lowers costs by cutting labor, equipment use, cargo damage, and port turnaround times significantly.

Specialized equipment and digital tools improve safety, reliability, and tracking of cargo throughout the supply chain.

Training a skilled workforce ensures efficient use of technology and helps maintain smooth, safe port operations.

Future trends like automation, sustainability, and digital transformation will make containerized bulk handling even more efficient and eco-friendly.

Challenges in Bulk Handling

Inefficiency Issues

Traditional bulk cargo handling at ports often leads to many inefficiencies. You may face long wait times because of slow processes or equipment breakdowns. Poor berth scheduling and vessel traffic management can cause congestion and delays. Equipment failures, such as broken conveyor belts or unavailable grabs, stop cargo movement. Inadequate infrastructure and poor maintenance reduce both efficiency and safety. The table below shows common inefficiency issues and their impacts:

Inefficiency Issue | Description | Impact/Example |

|---|---|---|

Inefficient Cargo Handling | Long wait times due to inefficient processes or equipment breakdowns | Delays in loading/unloading bulk cargo |

Suboptimal Berth Allocation & Traffic | Poor berth scheduling and vessel traffic management leading to congestion | Berth congestion and vessel delays |

Equipment Failure or Unavailability | Failure or lack of specialized equipment like conveyor belts, grabs, spouts, pumps | Delays in cargo handling |

Inadequate Infrastructure & Maintenance | Deteriorating port infrastructure such as berths and quay walls | Reduced operational efficiency and safety |

Congestion and Traffic Management | Traffic congestion within port premises and entry/exit points | Disruptions and delays in port operations |

Cargo Damage and Contamination | Damage or contamination of bulk materials during handling | Spoilage of grains, environmental hazards from chemicals/oil spills |

Environmental Risks | Risks related to spills and contamination, especially with liquid bulk cargo | Long-term environmental damage and costly cleanups |

You can see that these problems often lead to time delays. Manual clearing, equipment downtime, and interruptions in material flow all slow down operations. Poor management of goods flow and delays in shipping or customs make the situation worse.

Containerized Bulk Handling helps solve these issues by using standardized containers and automated systems. This reduces manual handling, speeds up loading and unloading, and keeps cargo safer.

Cost Factors

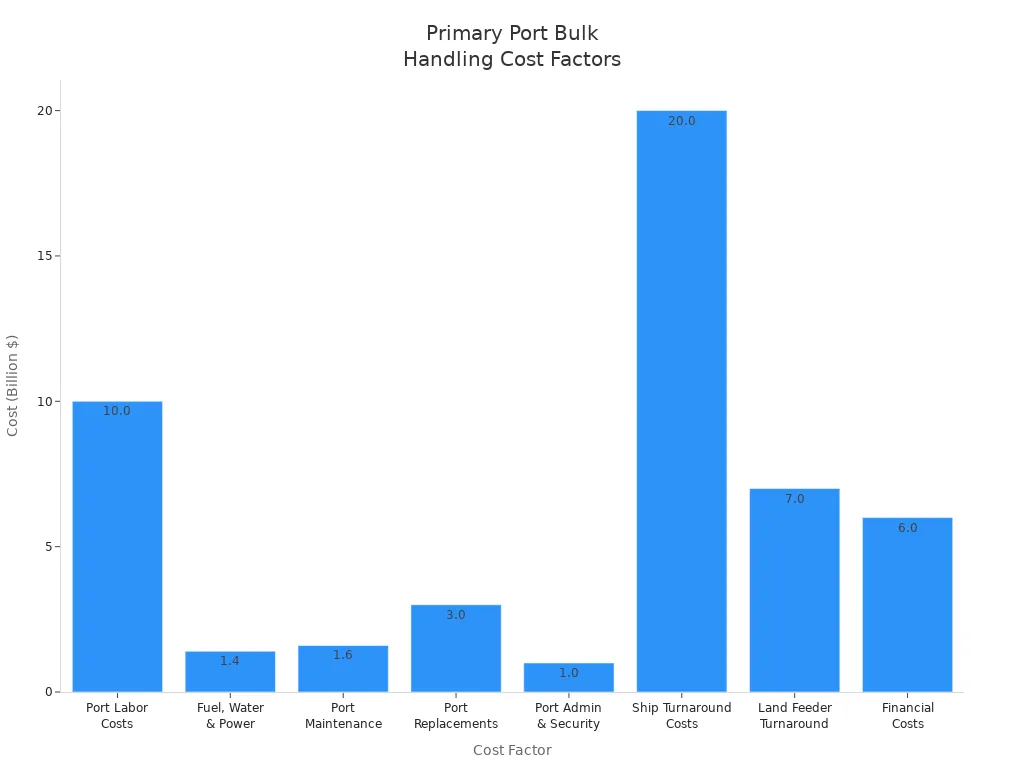

Handling bulk cargo the traditional way brings high costs. You pay for labor, fuel, maintenance, and ship turnaround time. The chart below shows the main cost factors in port operations:

Over half of port-related costs come from time lost during vehicle turnaround. Labor and equipment fees add up quickly. Port costs can reach almost half of all international transport expenses. When you use containerized systems, you cut packaging, labor, and cleaning costs. Faster loading and unloading also reduce labor time and port dwell times.

Reliability Concerns

Reliability is a big challenge in traditional bulk handling. Equipment faces heavy wear and tear from rough materials and impacts. Blockages and spillages can stop production and damage machines. Dust from bulk materials creates health and safety risks. Conveyor belts may track poorly, causing more breakdowns. You need regular maintenance and high-quality parts to keep things running.

Containerized Bulk Handling improves reliability by protecting cargo in sealed containers. This reduces manual handling and exposure to the environment. Standardized processes mean fewer delays and less damage. You can deliver cargo on time and keep your operations running smoothly.

Containerized Bulk Handling Benefits

Efficiency Gains

You can see a big improvement in efficiency when you use containerized bulk handling. Before containerization, workers loaded and unloaded cargo by hand. This process took a long time and needed many people. Ships often waited for days or even weeks in port. Now, with containerized bulk handling, you use machines and special equipment to move containers quickly. Ships spend less time in port and more time at sea. You can load or unload 1,000 TEUs in just 10 to 20 hours. In the past, this same job took 70 to 100 hours with bulk freight.

Tip: Shorter vessel turnaround times mean you can handle more ships and move more cargo each day.

Containerized bulk handling also helps you connect with trucks and trains more easily. This smooth link between sea and land transport keeps your supply chain moving fast. You do not need to spend time sorting or repacking cargo at the dock. Everything stays in its container from start to finish.

Reduced Cargo Damage

You protect your cargo better with containerized bulk handling. Traditional methods like Roll-on/Roll-off require a lot of manual work. This increases the risk of damage and makes it hard to prove when damage happens. Insurance claims become difficult because you cannot always show where or when the damage took place.

When you use containers, you seal your cargo inside. Cranes move the containers, so there is less handling and less chance for accidents. Your cargo stays safe from weather and outside elements. Insurance claims become easier to manage because you can track your cargo from start to finish. However, you should watch out for moisture inside containers. About 10% of goods in containers can get damaged by moisture, and insurance often does not cover this type of loss. You can reduce this risk by using proper packing and moisture control tools.

Cost Optimization

You can save a lot of money by switching to containerized bulk handling. Here are some of the main ways you cut costs:

Efficient bulk handling can lower logistics costs by up to 20% for industries that use a lot of materials.

Container transport reduces transport costs by about 20 times compared to bulk transport.

System-wide cost reductions of about 35% have been seen after ports switch to containerization.

Port turnaround times drop from weeks to less than 24 hours, saving on labor and dock fees.

Containers act as their own warehouse, which lowers damage and insurance costs.

Specialized containerization processes turn loose materials into easy-to-handle units, cutting down on handling steps and costs.

You can track containers digitally, which helps you avoid delays and extra expenses.

Note: When you use containerized bulk handling, you not only save money but also make your supply chain more reliable and easier to manage.

Key Technologies and Equipment

Specialized Handling Systems

You need specialized handling systems to move bulk cargo efficiently in modern ports. These systems help you load and unload materials quickly, safely, and with less environmental impact. One of the most advanced solutions is the RAM Revolver® system. This rotating spreader lifts container lids and tips bulk materials directly into ship holds. You can use it with sealed containers, which keeps dust and contamination to a minimum.

The RAM Revolver® works well with many types of bulk cargo, such as copper concentrate and wood pellets.

It fits with your existing port equipment, so you do not need to change your whole setup.

The system uses dry fog or misting around the ship’s hold to control dust during unloading.

Bulk containers reduce manual labor and prevent material loss or mixing.

You can use these containers as storage, transport, and loading tools, making your workflow more flexible.

Case studies show that ports like CODELCO and Riga Universal Terminal have used the RAM Revolver® to save costs and protect the environment. Port Elizabeth Container Terminal uses several RAM Revolvers® to handle large export volumes with zero dust emissions.

You also rely on other equipment like ship-to-shore cranes, mobile harbor cranes, and gantry cranes. These machines help move containers between ships, trucks, and trains. When you combine these tools with sealed bulk containers and dust suppression systems, you get the most effective setup for containerized bulk cargo.

Digital Solutions

Digital solutions make your port operations faster, safer, and more reliable. You can use Automated Guided Vehicles (AGVs) to move containers around the terminal. These vehicles lower accident risks and reduce labor costs. IoT devices let you track containers in real time, so you always know where your cargo is. Safety sensors on cranes and machines warn you about hazards, helping you avoid accidents.

AI-powered analytics help you plan the best routes for containers and predict possible delays.

Software tracks key performance indicators like order cycle time and on-time delivery rates.

Automated cranes speed up loading and unloading while keeping safety high.

Integrated ERP and Terminal Operating Systems (TOS) give you real-time updates on cargo and vessel status.

Intelligent workflows automate routine tasks and send alerts to the right people.

Proactive maintenance uses IoT sensors to check equipment health and prevent breakdowns.

Digital platforms, like the GIS-powered digital twin JP Glass at Jurong Port, show how real-time monitoring can improve efficiency. Staff can see vessel status, cargo handling, and equipment use all in one place. This helps you make quick decisions and keep operations running smoothly.

You can also use dashboards to see all your operations at a glance. These tools help you spot problems early and fix them before they cause delays. Digital solutions close the gap between traditional and containerized terminals by making your work more organized and efficient.

Skilled Workforce

A skilled workforce is key to safe and efficient containerized bulk cargo handling. You need workers who know how to use advanced equipment and follow safety rules. Training programs, like those from Mariner Skills and the Pacific Maritime Association, teach workers about container types, handling equipment, and safety standards. These programs follow international rules, such as the IMO International Convention for Safe Containers.

Training Program | Provider | Key Focus Areas | Description |

|---|---|---|---|

Breakbulk Shipping | Maritime Institute of Technology and Graduate Studies (MITAGS) | Practical handling, ship types, best practices | Keeps workers up to date with the latest logistics methods |

Breakbulk Shipping Certification | Learn America | Comprehensive breakbulk shipping knowledge, ABS approved | Gives advanced skills and industry-recognized certification |

Breakbulk Shipping | Mariner Skills | Transportation, vessel operations, documentation | Combines basic knowledge with practical skills for complex operations |

Breakbulk Shipping | American Digital University (ADU) | Multipurpose ships, project cargo, heavy lifts | Prepares workers for handling complicated shipments confidently and accurately |

You also need workers who can adapt to new technology. As you use more digital tools and automated systems, your team must learn new skills. Well-trained workers help you avoid cargo damage, reduce downtime, and keep your port running smoothly. When your workforce is flexible and multi-skilled, you can handle different tasks and respond to changes quickly.

Remember, a strong training program and a skilled team help you achieve higher productivity and better safety in containerized bulk handling.

Operational Strategies

Workflow Design

You can improve your port’s workflow by using advanced warehouse management software. This software helps you standardize tasks and make order fulfillment faster. Organize your inventory by labeling and using vertical space. This reduces mistakes and saves time. Lean warehousing means you keep only what you need, which cuts waste. Train your workers well and encourage them to share ideas. This boosts productivity and lowers costs. Standardized workflows make sure everyone follows the same steps. This helps you spot problems quickly. AI-powered tools can automate many tasks and connect with your current systems for better results.

Tip: Use automation like Automated Guided Vehicles (AGVs) and smart sensors to reduce manual work and keep your operations running smoothly.

IT Integration

IT systems help you manage all your cargo in one place. You can see real-time updates on yard planning, cargo movement, and vessel schedules. This makes it easier to plan and avoid delays. Automation tools, such as OCR and RFID, speed up gate checks and reduce waiting times. IoT sensors track container temperatures and alert you if something goes wrong. Data analytics help you spot bottlenecks and use your equipment better. With IT integration, you can control container moves, manage access, and keep your terminal safe and efficient.

Supply Chain Coordination

You can make your supply chain stronger by using smart loading plans. Transloading helps you use space and weight better. Palletizing goods makes handling easier and saves labor. Equipment like gantry cranes and reach stackers move containers quickly and use yard space well. Inventory management tools let you track goods during transfers. Sharing information with partners reduces congestion and speeds up turnaround. Always stack heavier items first and use dunnage bags to protect cargo. Portable ramps help you load goods into containers faster.

Decision Factors

When you choose a bulk handling solution, look at your trade volume, cargo type, and where your goods come from. Think about your financial resources and how much you can invest. Managerial skills matter for handling complex operations. Check your port’s equipment and if you have the right vessels. Consider how fast you need to deliver and if you can meet customs rules. Strategic planning helps you manage risks and keep your supply chain strong. Profitability, market access, and good relationships with shipping lines also play a big role.

Future Trends

Advanced Systems

You will see new systems changing how you handle bulk cargo in ports. Automated control systems now manage hard-to-flow solids in containers. These systems do not need tilting devices, which makes your work easier and cuts equipment costs. You get dust-tight emissions control, so you can handle harmful powders safely. Many ports use automated rubber-tired gantry cranes, rail-mounted gantry cranes, and terminal tractors. Automated guided vehicles and high-bay container storage also help move containers quickly and safely. These tools connect with plant control systems, giving you full visibility and better feedrate management. Some ports now use containerized bulk loading systems that boost grain loading capacity. This means you can move more cargo in less time and keep your port competitive.

Sustainability

You can make your port greener by using new container designs and smart transport plans. Some companies use secure, reusable container decks to cut waste and save raw materials. These designs let you load whole units without taking them apart, which lowers damage risk and saves energy. Route optimization software helps you plan the best paths, so you use less fuel and cut emissions. Intermodal transport lets you use ships, trains, and trucks together, which lowers energy use. Standardized containers carry more cargo per trip, so you make fewer trips and shrink your carbon footprint. Sealed containers protect sensitive materials from moisture and spoilage, which reduces waste. You also meet environmental rules more easily with emission monitoring tools and green technology.

Industry Outlook

You will see digital transformation shape the future of Containerized Bulk Handling. Autonomous vehicles, like self-driving trucks and robotic shuttles, will move containers around the port. Drones will deliver small packages quickly and safely. With 5G networks, your sensors and devices will talk to each other in real time. This helps you track cargo, spot problems early, and make better decisions. IoT sensors and AI analytics give you live updates and help you use containers more efficiently. Blockchain technology keeps your records safe and easy to check. These changes will help you deliver the right amount of cargo at the right time, with less damage and higher efficiency. You will save money, reduce delays, and give your customers better service.

To optimize Containerized Bulk Handling, you can follow these best practices:

Use automated carriers and robotic machines for fast container movement.

Employ gantry cranes and reach stackers for precise loading.

Separate import and export traffic to reduce congestion.

Integrate remote monitoring and real-time data for better planning.

Coordinate closely between crane operators and terminal staff.

Adopting efficient Containerized Bulk Handling and digital solutions helps you boost efficiency and stay competitive. As technology advances, you will see even greater improvements in port operations.

FAQ

What is Containerized Bulk Handling?

Containerized Bulk Handling lets you move bulk cargo in sealed containers. You use special equipment to load and unload these containers. This method keeps your cargo safe and speeds up port operations.

How does Efficient Containerized Bulk Handling reduce costs?

You save money with Efficient Containerized Bulk Handling. You need less labor and spend less time at the port. You also cut down on cargo damage and lower insurance costs.

What makes TR350R Containerized Bulk Handling and TCZ400R Containerized Bulk Handling special?

Both TR350R Containerized Bulk Handling and TCZ400R Containerized Bulk Handling use advanced technology. You get faster loading, better dust control, and safer cargo movement. These systems help you handle more cargo with less effort.

Why choose Stainless Steel Containerized Bulk Handling?

You pick Stainless Steel Containerized Bulk Handling for its strength and cleanliness. Stainless steel resists rust and keeps your cargo free from contamination. You can use it for food, chemicals, and other sensitive materials.

Related Blogs

-

You use a Container Rotating Spreader to lift sealed bulk containers, rotate them to the desired angle, and unload materials efficiently with minimal spillage. After unloading, you re-seal the containers for transport.Common benefits include:Improved efficiency and cost-effectivenessZero loss materi

You use a Container Rotating Spreader to lift sealed bulk containers, rotate them to the desired angle, and unload materials efficiently with minimal spillage. After unloading, you re-seal the containers for transport.Common benefits include:Improved efficiency and cost-effectivenessZero loss materi