A Container Rotating Spreader transforms bulk discharge operations by delivering higher efficiency, improved safety, and significant cost savings. This equipment streamlines unloading, protects operators, and minimizes spillage. Industry professionals choose models like high-capacity, heavy-duty, and TRQ380 for their adaptability. These solutions work seamlessly with Quay, Portal, Harbor, and Bridge Cranes, ensuring flexible integration and supporting both product quality and environmental protection.

Key Takeaways

Container Rotating Spreaders speed up unloading by rotating containers quickly and fully emptying bulk materials, helping ports handle more cargo in less time.

These spreaders improve safety by allowing remote operation and sealed handling, which protect workers from accidents and exposure to hazardous materials.

Using a Container Rotating Spreader reduces labor needs and lowers costs by automating unloading and minimizing manual work.

The equipment adapts to different container sizes and bulk materials, offering flexible use across various port operations.

Sealed systems and dust control features protect product quality and the environment by reducing spills and airborne dust during discharge.

Efficiency

Faster Unloading

A Container Rotating Spreader speeds up the unloading process for bulk materials. Operators can rotate containers quickly and discharge contents completely. This method reduces the time spent on each cycle. High-capacity models, such as the TRQ380, handle large volumes in a single operation. These spreaders work with Quay, Portal, Harbor, and Bridge Cranes. Teams can move more material in less time. This efficiency helps ports and terminals meet tight schedules and increase throughput.

Reduced Labor

Using a Container Rotating Spreader lowers the need for manual labor. Workers do not have to enter containers or use hand tools to remove leftover material. The equipment rotates and empties containers automatically. This process reduces physical strain on workers. Fewer people are needed on the ground, which also improves safety. Companies can reassign staff to other important tasks. Labor costs decrease, and productivity rises.

Less Downtime

Downtime can slow down operations and cause delays. A Container Rotating Spreader minimizes these interruptions. The equipment integrates easily with existing crane systems. Operators can switch between different container types without long setup times. Maintenance needs remain low because the design is robust and reliable. Quick discharge and easy handling keep equipment running smoothly. Ports and terminals experience fewer stoppages and maintain steady workflows.

Tip: Choosing the right model, such as a high-capacity or heavy-duty spreader, ensures the best fit for specific operational needs and maximizes efficiency.

Safety

Accident Reduction

A Container Rotating Spreader helps reduce workplace accidents during bulk discharge. Sealed container rotation keeps hazardous materials contained, so workers do not need to enter dangerous areas. Remote operation allows staff to control the equipment from a safe distance, even in harsh weather. This setup lowers the risk of slips, falls, and exposure to harmful substances. Many ports use water mist systems with these spreaders to control dust and improve air quality. The design meets strict safety standards, which further protects workers and the environment.

Certification/Standard | Description/Details |

|---|---|

ABS | American Bureau of Shipping certification ensuring marine equipment safety and quality |

CCS | China Classification Society certification for marine equipment |

DNV(GL) | Det Norske Veritas / Germanischer Lloyd certification for quality and safety |

RMRS | Russian Maritime Register of Shipping certification |

NK | Nippon Kaiji Kyokai (ClassNK) certification for marine equipment |

Rina | Registro Italiano Navale certification |

KR | Korean Register certification |

CE | European Conformity marking for safety and environmental compliance |

ISO | International Organization for Standardization certifications ensuring quality management |

SGS | Société Générale de Surveillance certification for inspection and verification |

Operator Protection

Operators stay safer when using remote controls to manage the spreader. They do not need to stand near moving containers or bulk materials. This distance protects them from falling objects and dust. Remote operation also reduces human error, making the process more reliable. In poor weather, such as high winds or rain, operators can work from a secure location. This feature keeps them out of harm’s way and supports a safer work environment.

Note: Full load and function testing, along with operation and maintenance manuals, come with every spreader. These steps ensure that operators understand safe handling procedures.

Sealed Handling

Sealed handling systems play a key role in safety during bulk discharge. UN-certified bulk bags and valves prevent leaks and exposure to hazardous materials. Iris valves and glove boxes let operators open bags without direct contact, reducing the risk of dust or spills. Access doors and airtight seals keep harmful substances contained. This approach protects both workers and the environment.

Improved material containment prevents leaks and spills.

Reduced manual handling lowers injury and exposure risks.

Airtight seals ensure compliance with safety regulations.

Regulatory bodies require equipment that limits dust and cargo loss. Container Rotating Spreader systems meet these rules by using enclosed or dust-minimizing features. This compliance helps ports operate safely and efficiently.

Cost Savings

Lower Labor Costs

A port or terminal can lower labor costs by using a Container Rotating Spreader. This equipment automates the unloading process. Workers do not need to enter containers or handle bulk materials by hand. Fewer people are needed on the ground. Teams can focus on other important tasks. Companies save money on wages and training. The risk of injury also drops, which reduces costs related to workplace accidents.

Faster Turnaround

Faster turnaround is a key benefit for busy ports. The Container Rotating Spreader allows operators to unload bulk cargo quickly and efficiently. Cranes can rotate and empty containers in one smooth motion. This speed helps ships spend less time at the dock. More ships can move through the terminal each day. Customers receive their goods faster, which improves satisfaction and business reputation.

Tip: Quick integration with existing crane systems means ports do not need to build new infrastructure. This saves both time and money.

Equipment Longevity

Using a Container Rotating Spreader helps extend the life of other equipment. The spreader handles heavy loads and tough materials with a strong, reliable design. Cranes and other machinery experience less wear and tear. Maintenance needs decrease, and equipment lasts longer. Ports spend less on repairs and replacements. This long-term saving adds up over time.

Portable design allows easy movement between sites.

Simple setup reduces downtime and keeps operations running smoothly.

Flexibility

Multiple Container Types

A Container Rotating Spreader offers unmatched adaptability for ports and terminals handling a wide range of container types. Operators can manage standard 20-foot and 40-foot containers, as well as dual 20-foot configurations. The equipment features adjustable center clearance and a hydraulic separation system, which allows independent lifting of containers with different sizes or weights. High-strength European steel construction ensures durability, even when handling heavy, damaged, or irregular containers. The table below highlights key features that support this versatility:

Feature | Details |

|---|---|

Compatible Container Sizes | 20 feet, 40 feet, dual 20-foot containers (2×20 feet) |

Lifting Modes | Single Lift: 40T–50T; Dual Lift: two 20-foot containers simultaneously |

Adjustable Center Clearance | Handles non-standard spacing in dual lift mode |

Hydraulic Separation System | Independent lifting for different sizes and weights |

Construction Material | High-strength European steel for harsh environments |

Safety Compliance | Meets EN13001 standards |

Application | Ship-to-shore cranes, heavy or irregular containers |

Bulk Material Adaptability

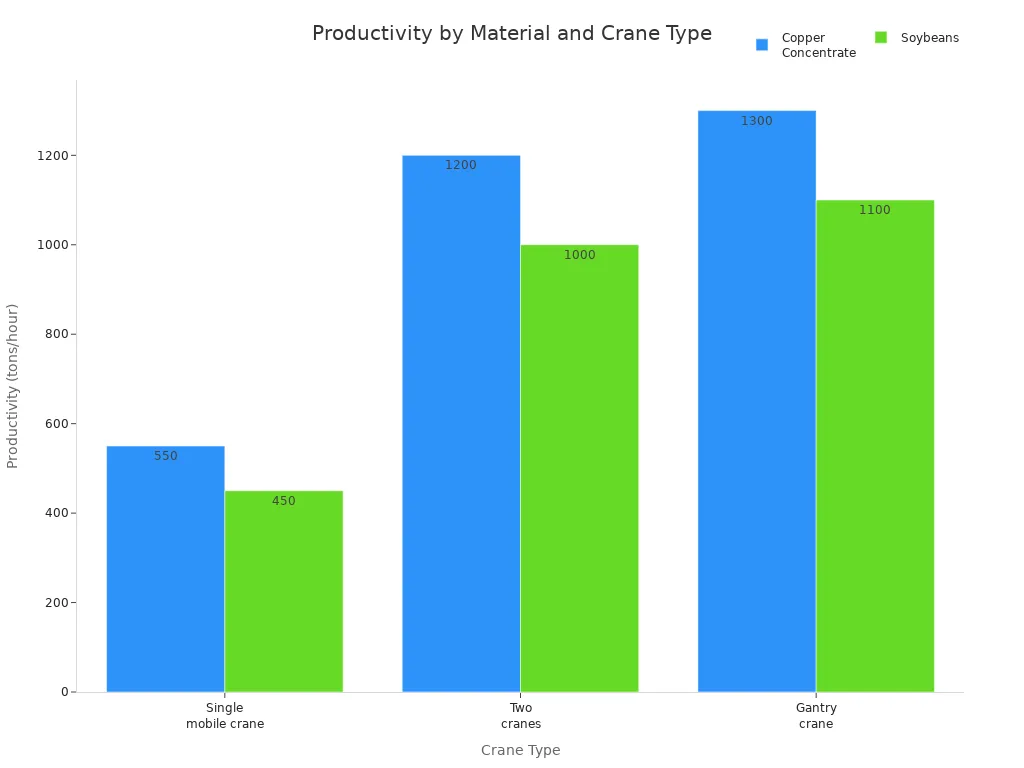

Operators rely on container rotating spreaders to handle a variety of bulk materials, from metallic powders to agricultural products like soybeans. The design includes features such as hermetically sealed lids and internal structures that prevent product retention and ensure complete discharge. For example, copper concentrate containers use an internal ice cube wall design to avoid hang-ups, while soybean containers use high cube designs for lighter loads. The system supports high productivity across different crane types, as shown in the chart below:

Additional adaptations, such as misting systems at the ship’s hold entrance, help control dust and protect both workers and the environment.

Easy Integration

Quick changeover and remote control features make operations more convenient and efficient. The battery swap system allows for continuous use with minimal downtime, often less than 15 minutes. Remote controls enable precise load orientation, with fine adjustments possible in 1° increments. This technology reduces the number of riggers needed and increases safety by keeping workers away from the drop zone. Operators can maintain productivity even in challenging conditions, such as high winds, by using the “hold” function. These features support seamless integration with existing port equipment and help teams complete projects faster.

Product & Environment

Quality Preservation

Controlled rotation during bulk discharge helps protect the quality of bulk materials. The Container Rotating Spreader rotates containers smoothly, which prevents sudden drops or jolts that can damage fragile products. Sealed containers keep materials safe from outside contaminants, such as dust or moisture. This method reduces the risk of product loss and ensures that materials arrive at their destination in the best possible condition. Operators can handle sensitive cargo, like grains or powders, with confidence that the product will remain intact and uncontaminated.

Reduced Spillage

Spillage often leads to product loss and environmental harm. The use of sealed containers and precise rotation technology minimizes these risks. Operators can discharge bulk materials directly into the desired location, reducing the chance of spills on the dock or ship. Sealed handling systems, including UN-certified bulk bags and airtight valves, keep materials contained throughout the process. This approach not only saves valuable product but also helps ports meet strict environmental regulations.

Sealed enclosures for bulk storage reduce dust and spillage.

Atomized mist and water sprinklers control dust and prevent material from escaping.

Regulatory actions encourage the use of sealed containers and dust suppression systems.

Dust Control

Dust control remains a top priority in bulk discharge operations. The integration of misting systems with the Container Rotating Spreader provides an effective solution. These systems spray a fine water mist around the ship’s hold entrance, creating a barrier that traps dust particles before they escape into the air. Environmental studies show that atomized mist technology, which uses droplets between 50 and 200 microns, captures airborne dust more efficiently than traditional sprinklers. This method uses less water, reduces runoff, and keeps both the product and the environment safe. Scientific models also help ports predict dust pollution and take preventive steps, supporting cleaner and safer operations.

Note: Dust suppression systems not only protect workers and nearby communities but also help facilities comply with environmental standards.

A Container Rotating Spreader delivers efficiency, safety, and cost savings for bulk discharge operations. Companies gain value by investing in high-capacity or heavy-duty models for Quay, Portal, Harbor, or Bridge Cranes. Industry experts recommend the following steps for modernizing bulk handling:

Embrace automation and digital technologies to boost productivity.

Optimize container utilization and ensure regulatory compliance.

Adopt eco-friendly solutions and robust security measures.

Ports that upgrade to advanced equipment position themselves for long-term success.

FAQ

What types of cranes work with a Container Rotating Spreader?

Operators can use a Container Rotating Spreader with Quay, Portal, Harbor, and Bridge Cranes. These spreaders fit many crane models, making them suitable for different port and terminal setups.

How does a High-Capacity Container Rotating Spreader improve safety?

A High-Capacity Container Rotating Spreader uses sealed handling and remote controls. This design keeps workers away from hazardous materials and moving equipment, reducing the risk of accidents.

Can a TRQ380 Container Rotating Spreader handle different bulk materials?

Yes. The TRQ380 Container Rotating Spreader adapts to various bulk materials, including powders, grains, and minerals. Its design ensures complete discharge and prevents product loss.

What maintenance does a Heavy-Duty Container Rotating Spreader require?

Regular inspections and cleaning keep a Heavy-Duty Container Rotating Spreader in top condition. Operators should check hydraulic systems, seals, and control units to ensure reliable performance.