Products

High-Capacity Rotating Spreader for Quay Cranes

Container spec.

20ft、40ft

Rated load

38t

Weight

11.5t /15.0t

Applicable Product

Quay Crane

Product Introduction

The Rotating Spreader for Quayside Crane by Hunan Tona Machinery Technology Co., Ltd. is a specialized attachment designed for efficient tilting of 20ft and 40ft open-top containers. It is widely used in cargo yards and ports, particularly in high-demand environments like those serviced by Tona’s innovative equipment. The spreader is perfect for loading and unloading bulk materials such as coal, iron powder, ore, and grains. It features 360-degree rotation for flexible and precise container handling, boosting operational efficiency and port productivity.

Built with high-strength materials and designed with safety features, the spreader ensures secure and efficient handling during operations. As part of Tona's commitment to high-quality, customized solutions, it is compatible with ship-to-shore cranes and rubber-tired gantry cranes, enhancing cargo handling and optimizing operations across a variety of industries. Tona’s focus on innovation and customer satisfaction ensures that the spreader meets the highest standards in functionality and performance.

The High-Capacity Rotating Spreader for Quay Cranes is a revolutionary cargo handling solution designed to optimize container operations in ports and terminals. Engineered to handle standard 20-foot, 40-foot, and 45-foot containers, this spreader features a robust steel frame with a maximum load capacity of 65 metric tons, ensuring safe and efficient handling of even the heaviest marine containers. The integrated 360° rotating mechanism allows precise container positioning without repositioning the crane, reducing cycle times by up to 40%.

Equipped with advanced load-sensing technology and hydraulic locking systems, the spreader guarantees secure container engagement and disengagement. Its weather-resistant design, including anti-corrosive coatings and IP67-rated electrical components, ensures reliable performance in harsh marine environments. The spreader connects seamlessly with all major quay crane models, featuring standardized interface protocols for quick installation and compatibility.

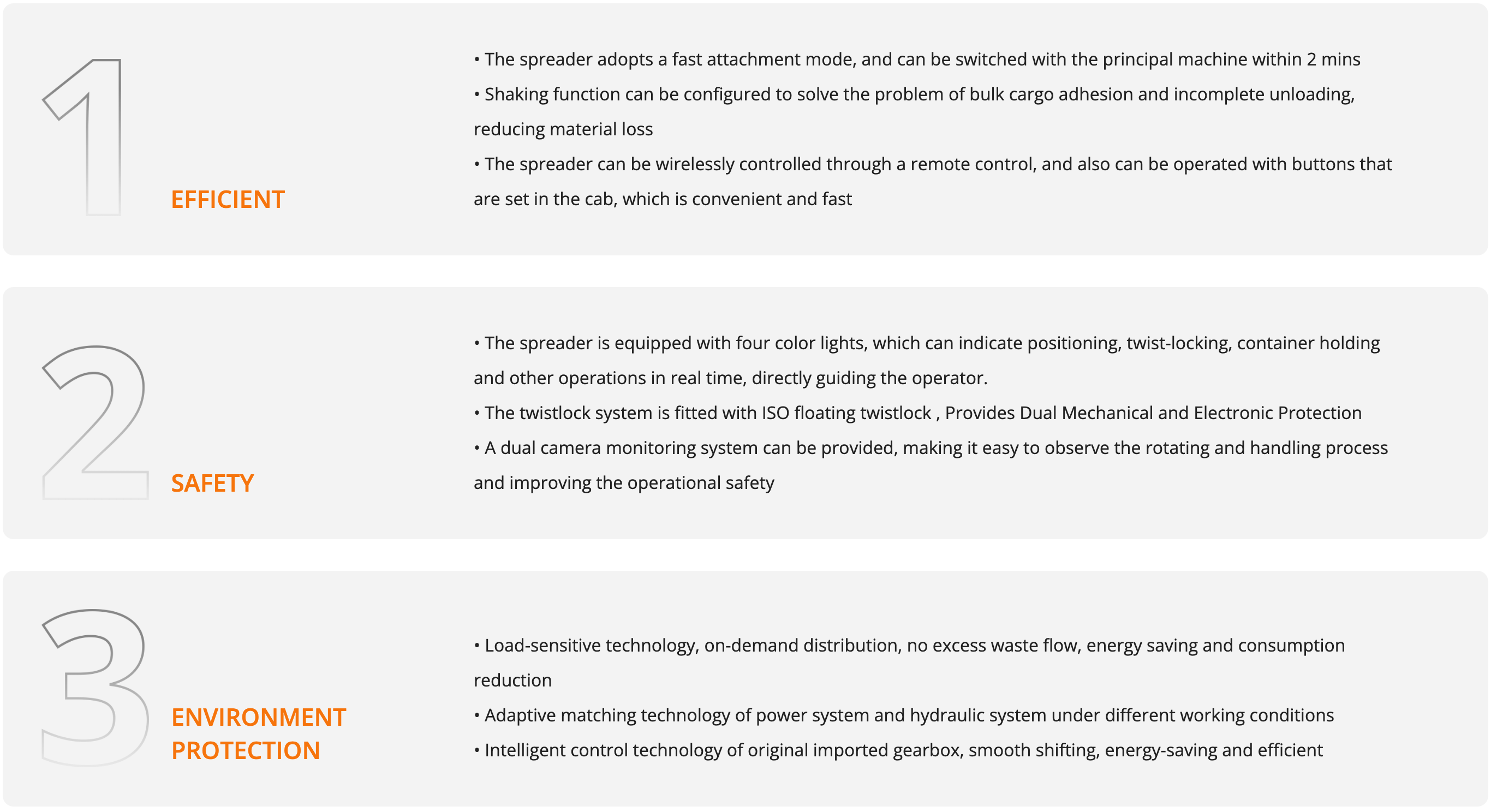

Product Features

4.High Load Capacity

Handles containers up to 65 tons, accommodating loaded 45-foot high-cube containers commonly used in international shipping.

5.360° Rotation

The precision planetary gear system enables smooth, stepless rotation, eliminating the need for crane repositioning and improving operational efficiency.

6.Smart Locking System

Hydraulic twistlocks with optical and mechanical sensors ensure positive container engagement, with real-time status feedback to the crane operator.

7.Durable Construction

Built with marine-grade steel and anti-corrosive epoxy coatings, resisting saltwater corrosion and extreme weather conditions.

8.Easy Integration

Standardized electrical and mechanical interfaces allow compatibility with 95% of existing quay cranes, reducing retrofitting costs.

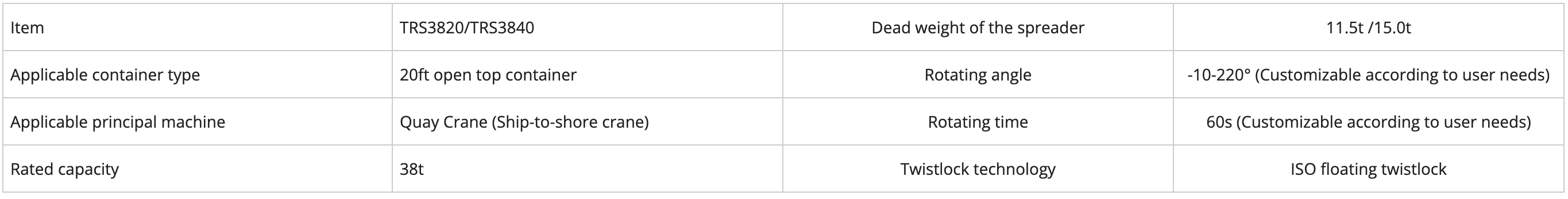

TECHNICAL PARAMETER

Product Application Scenarios

The Rotating Spreader for Quayside Cranes by Hunan Tona Machinery Technology Co., Ltd. is ideal for operations at busy ports, cargo yards, and docks. It efficiently handles 20ft and 40ft open-top containers, making it perfect for transferring bulk materials such as coal, iron powder, ore, and grains between containers and ship holds.

This spreader excels in quayside operations, seamlessly integrating with ship-to-shore cranes, rubber-tired gantry cranes, and other crane types. As part of Tona’s dedication to providing high-performance equipment, the spreader is designed to handle large volumes of cargo quickly and safely, enhancing port productivity. Its ability to optimize storage space and reduce operational time aligns with Tona's commitment to innovative solutions that improve the efficiency of containerized bulk material handling in global logistics operations.

Port Terminals:

Essential for loading and unloading containers from ships to shore, optimizing cargo throughput in busy maritime hubs.

Rail & Road Interchange:

Facilitates seamless transfer of containers between ships, trains, and trucks in intermodal logistics centers.

Heavy Cargo Handling:

Suitable for transporting oversized or heavy industrial equipment packed in specialized containers.

Offshore Platforms:

Used in offshore logistics to handle supply containers in harsh marine environments with high wind and wave conditions.

FAQ

Q: What types of containers are compatible with the spreader?

A: The Rotating Spreader is designed to handle 20ft and 40ft open-top containers, making it suitable for bulk cargo operations in ports, docks, and cargo yards.

Q: Does the spreader require any special maintenance to ensure long-term operation?

A: Regular inspections and maintenance of the twistlock system, hydraulic components, and safety features are recommended to ensure optimal performance and longevity.

Q: What are the environmental benefits of using the Rotating Spreader in terms of energy consumption and efficiency?

A: The spreader uses load-sensitive technology and an adaptive power system to optimize energy consumption, reducing waste and environmental impact while enhancing performance.

Q: Can the spreader be controlled remotely, and if so, how far can the operator be from the equipment?

A: Yes, the spreader can be controlled via a wireless remote control, allowing operators to control it from a safe distance, ensuring efficient and safe handling operations.

Q: What safety features are built into the Rotating Spreader?

A: The spreader features four color lights for real-time visual guidance, dual camera monitoring for safety, and an ISO floating twistlock system with mechanical and electronic protection for secure container handling.

Q: How long does it take to switch between container sizes?

A: The automatic size detection system adjusts the spreader width in less than 15 seconds, eliminating manual adjustments.

Q: What is the maintenance interval for the rotating mechanism?

A: Lubrication is required every 500 operating hours, and gearbox oil should be changed annually.

Q: Can it handle refrigerated containers (reefers)?

A: Yes, the spreader is compatible with reefer containers, with optional electrical connections for powering refrigeration units.

Q: Is remote diagnostics available?

A: Yes, the spreader includes an IoT-enabled monitoring system that transmits performance data to a centralized control room.

CONSTRUCTION CASES