You should always focus on safety and following rules when you handle containerized bulk handling. This keeps workers and cargo safe. Many companies now use Efficient Containerized Bulk Handling and High-Speed Containerized Bulk Handling for better results. These solutions are popular because they help move cargo fast, lower risks, and make work easier.

Over 90% of world trade now uses container shipping. This moves huge amounts of cargo every year.

The Asia-Pacific region is the leader in containerized bulk handling. North America and Europe are getting better with new technology.

Ports like Shanghai move more than 40 million TEUs of cargo each year. This shows why strong cargo handling systems are important.

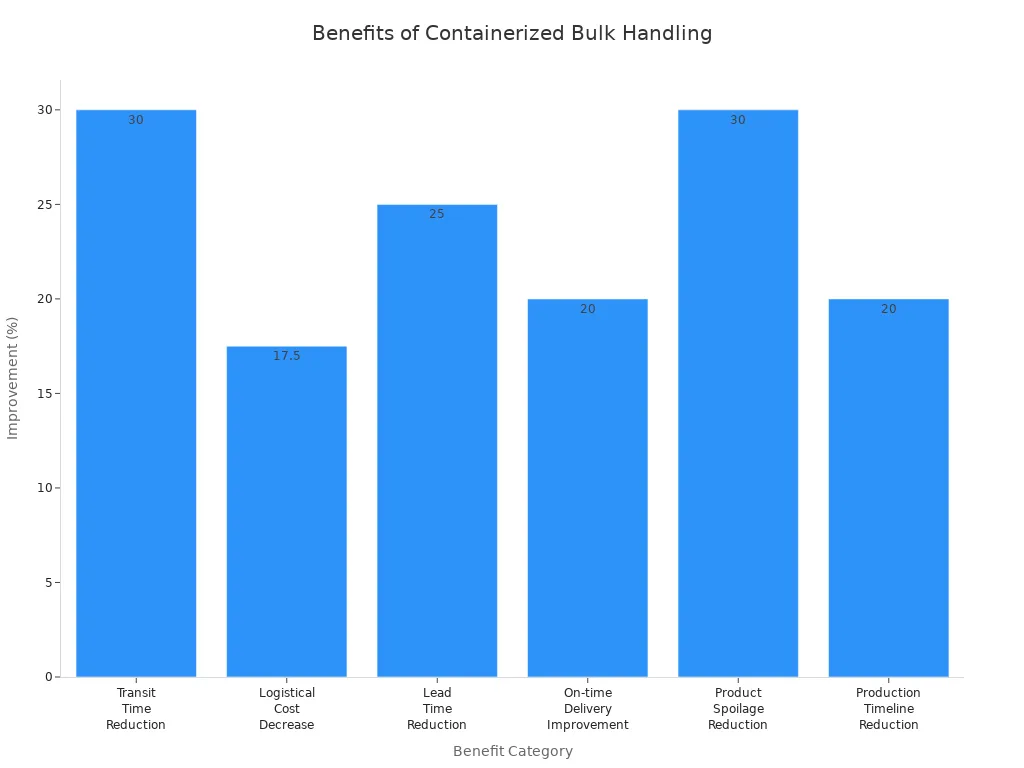

You can see clear benefits when you use best practices in cargo handling:

Benefit Category | Measurable Improvement | Description |

|---|---|---|

Transit Time Reduction | 30% | IoT-enabled container tracking made transit times much shorter in logistics work. |

Logistical Cost Decrease | 15-20% | Many reports show lower costs by using containers better. |

Lead Time Reduction | 25% | Using standard containers made lead times shorter in stores and factories. |

On-time Delivery Improvement | 20% | Better container management helped deliveries arrive on time. |

Product Spoilage Reduction | 30% | Refrigerated containers with IoT checks kept products from spoiling in healthcare. |

Production Timeline Reduction | 20% | Containerization helped JIT delivery and cut down on production delays in factories. |

Accident and Damage Risk | Reduced | Good training and new technology lowered accidents, damage, and theft. |

When you use these best practices, you make cargo handling safer and more dependable. You also help your team work faster and keep cargo damage low.

Key Takeaways

Always put safety first and follow all rules to keep workers and cargo safe during containerized bulk handling.

Pick the right container type for your cargo, and check and clean containers before using them to stop damage and contamination.

Load containers with care by spreading weight evenly, filling empty spaces, and tying down cargo to stop accidents and product loss.

Use new tracking and monitoring systems to watch cargo as it moves, work faster, and fix problems quickly.

Train your team often and go over steps to make sure cargo handling stays safe, works well, and uses new technology.

Preparation

Container Selection

Picking the right container is very important. You need to know what you are moving. Is it a liquid, powder, or solid? Some cargo needs extra care, like food or chemicals. Stainless Steel Containerized Bulk Handling is good for these. It keeps things safe and is easy to clean. If you move chemicals or fuels, TR350R Containerized Bulk Handling and TCZ400R Containerized Bulk Handling work well. They are strong and safe. They also follow the rules.

Here are some tips to help you choose a container:

Check what kind of cargo you have and how much.

Make sure the container material matches your cargo. Use metal for chemicals, food-grade plastic for food, and cardboard for dry goods.

Pick containers that are simple to move and stack.

Choose containers with good locks and seals to keep things safe.

Think about your budget and how you manage your supply.

Container Type | Example | Advantages | Use Case |

|---|---|---|---|

Stainless Steel | Stainless Steel IBC | Clean, strong | Food, pharma |

Plastic | Plastic IBC | Light, reusable | Chemicals, food |

Metal | Tough, safe | Construction, fuel |

Inspection & Cleanliness

Always check and clean containers before you use them. This keeps your cargo safe. It also protects your supply. Use green cleaners and strong wash guns. Teach your team to use cargo handling equipment the right way. Clean corners and hard spots well. Take out old cargo, oil, and dust. Look for leaks or damage. Make sure all locks and seals work. Checking containers often helps stop problems. It keeps your supply chain working well.

Tip: Use a checklist every time you inspect. This helps you find small problems before they get big.

Compliance & Documentation

You must follow rules when you move containerized cargo. There are international laws like the International Convention for Safe Containers (CSC) and the IMDG Code. These set safety rules. Always keep records for your cargo. This includes cleaning logs, safety sheets, and shipping papers. Use the right container for dangerous or safe cargo. Share all needed papers with your supply partners. This keeps your project safe and legal. Following rules also helps your supply chain and makes things work better.

Loading Best Practices

Filling Techniques

When you load containers, you need to use good cargo handling steps. Start with a clear packing plan. This plan helps you use all the floor space. It also helps stop gaps from forming. Fewer gaps mean cargo will not move around. Put the heaviest cargo in the middle and at the bottom. Lighter things should go on top. This keeps the center of gravity low. It makes cargo handling safer for everyone.

Here are some easy steps for filling containers well:

Cover the floor so there are no empty spots.

Spread the weight from side to side and end to end.

Put heavy cargo at the bottom and lighter cargo on top.

Use vertical separators and interlocking stows for upper layers.

Hold cargo in place with dunnage and lashings.

Do not pack cargo together if it does not mix well.

Use two layers of dunnage for more safety.

Fill spaces with small boxes or wedges.

Check your paperwork and look over the cargo before shipping.

You should use pallets that are not broken. Put heavy boxes on the bottom layer of pallets. Stack boxes with the strong side up for support. Fill the pallet space but do not let boxes hang off. Use void fill to stop empty space in cartons. These steps help you follow good cargo handling and lower the chance of damage.

Tip: Always figure out the total cubic meters (CBM) before loading. This helps you not overload the container and keeps cargo handling smooth.

Weight Distribution

Good weight balance is very important for safe cargo handling. If the load is not balanced, the container can tip or move. This can hurt the cargo and workers. Even weight also helps you avoid fines and delays at ports.

Even weight keeps the container steady during cargo handling.

Loads that are not balanced can break the container or truck.

Containers that are too heavy can cause accidents and cost more money.

You should make a careful loading plan. Put heavy cargo at the bottom and in the middle. Hold the load with straps, nets, and dunnage. Measure goods well and use modular packing to keep balance. Always follow safety rules and wear personal protective equipment (PPE) when handling cargo.

Note: The Verified Gross Mass (VGM) rule says you must tell the right weight of each container. This rule helps stop accidents and keeps cargo handling safe.

Liners & Protection

Liners and other protection are important for good cargo handling. They keep bulk cargo safe from water, dirt, and heat or cold. You can pick from many liners like polyethylene (PE), polypropylene (PP), high-density polyethylene (HDPE), and aluminum foil. These liners make a barrier to keep cargo safe while moving.

Thermal liners help control water and temperature.

Aluminum foil liners bounce heat away and keep cargo cool.

Container liners fit inside containers and protect dry cargo like grains.

Agricultural liners and bulkhead systems keep crops safe from rough spots and dirt.

Pick liners based on what you are moving, how hot or cold it is, and how long it will travel. Liners are easy to put in and take out. They also help you load and unload cargo faster, making cargo handling better.

Remember: Using the right liners, dunnage, and bracing is one of the best ways to handle cargo. These tools keep cargo safe and lower the chance of damage.

Liner Type | Material | Best Use Case | Key Benefit |

|---|---|---|---|

Thermal Liner | Aluminum Foil | Temperature-sensitive cargo | Controls heat and moisture |

Container Liner | PE, PP, HDPE | Dry bulk cargo | Prevents contamination |

Agricultural | Custom Fabrics | Crops, grains | Protects from rough surfaces |

Always check liners before you use them. Make sure there are no holes or rips. This is part of good cargo handling and helps you avoid big mistakes.

Studies show that 65% of cargo damage comes from bad packing and not securing cargo. If you follow these good cargo handling steps, you can avoid these problems.

Transportation & Cargo Handling

Safe Movement

You help keep cargo safe when it moves in containers. Good cargo handling needs the right tools and a good plan. Always use forklifts with seat belts and cameras. Pick the right attachments for your cargo handling systems. When you move containerized cargo, keep the forks straight and the load even. Use straps or chains to hold containers in place.

Follow these steps for safe cargo handling:

Use carts or lifting tools to avoid lifting by hand.

Plan your path and look for bumps or things in the way.

Put containers on strong racks or pallets so they do not fall.

Teach your team what to do in an emergency and how to give first aid.

Make sure everyone wears safety gear and has spill kits.

Tip: Check your cargo handling systems before you use them. Inspections help you find problems early and keep cargo handling safe.

Do not move chemicals that do not mix well together. Use extra containers for chemicals to stop spills. Never put too much on your equipment. Follow safety rules to keep cargo handling smooth and safe.

Monitoring in Transit

You need to watch cargo while it moves to keep it safe and on time. Modern cargo handling systems use RFID tags and tracking tools for containerized bulk handling. These tools show you where your cargo is right now. You can see your containerized cargo at any time. This helps you find delays and fix problems fast.

Many ports use Terminal Operating Systems (TOS) and IoT sensors. These systems track cargo and equipment as they move. You get live updates to help you use your resources better. Some ports, like Jurong Port in Singapore, use digital twin systems. These systems watch cargo, equipment, and weather all day and night.

RFID technology makes cargo handling better by tracking things automatically. You make fewer mistakes and work faster in cargo handling operations. You also keep better track of your inventory and lose fewer items. Real-time tracking helps you act fast if something goes wrong.

Note: Tracking systems for containerized bulk handling make your cargo handling safer and faster.

When you move bulk in containers, these tools help you move cargo on ships, trucks, and trains without losing it. You keep cargo safe and your cargo handling systems working well.

Hazardous Materials

Handling hazardous materials in containerized cargo needs special care. You must follow strict rules to keep people safe. First, figure out what kind of cargo you have. Use the right packaging and put clear labels on each container. Always use UN-rated containers for hazardous materials.

Here are best ways to handle hazardous cargo:

Teach your team about hazard classes and what to do in an emergency.

Use approved packaging and put hazard labels on containers.

Keep shipping papers like Bills of Lading and Dangerous Goods Declarations.

Hold the load in place so it does not move.

Never move chemicals together if they do not mix well.

Give your team PPE and spill kits.

Follow DOT, IATA, and IMDG Code rules for each way you move cargo.

Tell someone right away if there is a spill or problem.

Always have emergency plans ready and practice drills often. This keeps your cargo handling systems ready for anything.

You must get an EPA Identification Number if you move hazardous waste. Use the EPA’s manifest system to track your shipments. If a spill happens, act fast and tell the right people. These steps keep people, the environment, and your cargo handling operations safe.

By following these rules and using new cargo handling systems, you keep your cargo safe from start to finish.

Unloading & Post-Handling

Unloading Methods

You must use the right way to unload cargo. This keeps your cargo safe and helps your supply chain. Bulk containers save time and need less work. This lowers the chance of damage or spills. It also helps stop product loss during cargo handling. Less touching of packaging means less chance of contamination. Always use trained operators who know safe cargo handling. They help you avoid mistakes that could hurt your cargo or supply.

There are different containers for different cargo. ISO tanks, flexitanks, and IBCs are some examples. These containers keep cargo safe while unloading. Bulk transportation uses less extra packaging. This helps stop contamination and is better for the environment. Always check your port or terminal before unloading. Good setups make cargo handling faster and safer for your supply.

Tip: Use dust control systems like dry fog or mist when unloading. These systems help stop dust and pollution. This keeps your cargo and supply clean and safe.

Damage Inspection

After unloading, you need to check for damage. Start by looking for any problems or missing items. Use a checklist to look for damage or contamination. Make sure your cargo matches the shipping papers. This step keeps your cargo handling honest and clear.

Look at the cargo for damage or loss.

Write down the condition and any problems.

Get approval from customs or safety staff.

Clean and check the cargo hold for safety.

Make sure lights and air systems work well.

Quality checks are important after cargo handling. They help you know if your cargo meets supply rules. Always write down what you find to help your supply chain.

Cleaning for Reuse

Cleaning containers for reuse is very important. Wear safety gear and make sure there is fresh air. Empty the container and throw away leftover cargo safely. Wash the container with water or a safe cleaner. Use brushes or pressure washers to clean all sides. Rinse again until nothing is left.

Dry the container all the way before using it again. Check for cracks or other damage. Store clean containers in a dry place to keep your supply safe. If a container is not safe, follow local rules to recycle or throw it away.

Remember: Clean containers help stop contamination. This keeps your cargo safe and makes your cargo handling strong. It also helps your supply stay reliable.

Technology & Innovation

Tracking Systems

You can make cargo handling smarter with tracking systems. Smart containers use IoT devices and RFID tags. These tools show you where your cargo is all the time. You get updates on location, temperature, and if the container opens. This helps you find problems early.

Tracking systems help you in many ways:

Real-time tracking lets you see your cargo at any time.

IoT sensors check temperature and humidity inside containers.

RFID tags help you find containers fast in busy places.

Data analytics show delays, bottlenecks, and your carbon footprint.

Better tracking helps you and your partners fix problems quickly.

Benefit Category | Description | Measurable Impact / Example |

|---|---|---|

Cost Savings | You pay fewer fines and detention costs. | Save $300K-$500K each month; $10 million a year in detention costs. |

Capacity Utilization | Working together helps you use more space. | 4% better use of space across the industry. |

Operational Efficiency | Automation and alerts help you fix problems faster. | You can focus on solving issues, not just tracking shipments. |

Visibility and Monitoring | Real-time tracking gives you detailed information. | You see delays, bottlenecks, and your carbon footprint. |

Supply Chain Collaboration | Partners work together better, like Kraft Heinz did. | Shipments improved during the COVID-19 pandemic. |

Automation & Digital Docs

You can make cargo handling faster with automation and digital documents. Automated Guided Vehicles and robotic cranes move cargo quickly and with fewer mistakes. Digital paperwork, like electronic customs forms, makes clearing cargo easy. You do not lose papers or wait for slow approvals.

Automation means less manual work and faster cargo handling.

Digital documents lower mistakes and help you follow rules.

Real-time checks stop delays and fines.

Smart systems use AI to plan the best cargo routes.

You save time and money, making cargo handling better.

Flexitanks, pump-based loading, and single-use designs help move more cargo safely. These new tools make cargo operations safer and faster. High-Speed Containerized Bulk Handling and Efficient Containerized Bulk Handling use these tools for better results.

Training & Improvement

Staff Training

You need good training to keep cargo handling safe. Training helps you and your team learn each step. You find out how to use equipment and follow safety rules. You also learn how to manage cargo in the yard. Lessons with videos and group talks make learning simple. These ways help you remember the best cargo handling steps.

Aspect | Details |

|---|---|

Training Focus | Container yard management, equipment, operational best practices, safety, and efficiency |

Learning Methods | Interactive, participative sessions with discussions, videos, and animations |

Organizational Benefits | Improved understanding of container yard operations, equipment management, safety, and operational efficiency |

Personal Competencies Developed | Practical yard management skills, container tracking, use of automated systems, best practices in container storage and movement |

Target Audience | New entrants, terminal planners, operators, freight forwarders, shipping agents, maritime legal and insurance professionals |

Course Outline Highlights | Introduction to container business, container types and ships, yard configuration, terminal planning and management |

You should pick courses that teach about container types and cargo. Training shows you how to use cranes and other cargo handling tools. You also learn about safety checks and following rules like the IMO International Convention for Safe Containers. This training helps you build skills and handle cargo with care.

Procedure Review

You must check your cargo handling steps often. Regular checks keep cargo handling safe and up to date. Standard operating procedures (SOPs) help you avoid mistakes. SOPs give you clear steps for each cargo handling job. They also help you follow safety rules and keep cargo safe.

SOPs help keep workers safe and make cargo handling better.

They lower mistakes and help you work faster with cargo.

SOPs make sure you follow all cargo handling rules.

They give you checklists for cargo and equipment checks.

SOPs help you train new workers in cargo handling.

You should check your cargo handling steps every year. This keeps your cargo handling current with new rules and technology. When you update your steps, you protect your team and your cargo. You also make cargo handling faster and more reliable.

Tip: Keep your SOPs easy to read. Use checklists and clear steps for each cargo handling job. This helps everyone follow the same process and keeps cargo safe.

You can make containerized bulk handling safer and faster by using good steps. Always plan how you will move your cargo. Spread the cargo weight so it is even. Use the right tools for each kind of cargo. Teach your team how to handle cargo safely. Watch the cargo at every step. Change your steps often to use new technology and follow new rules. Big companies like Toyota and Amazon use new ways to get better cargo quality. They also save money and make their supply chains stronger. Pick Efficient Containerized Bulk Handling to keep your cargo safe and stay ahead.

FAQ

What is containerized bulk handling?

Containerized bulk handling is moving lots of materials in containers. This way keeps materials safe and makes moving them easier. Many businesses use it because it is safe and helps them work faster.

Why should you choose stainless steel containers?

Stainless steel containers are strong and last a long time. They do not rust and are simple to clean. You can use them for food, chemicals, and other things that need care. They help you follow safety rules.

How do tracking systems help you?

Tracking systems show you where your shipment is right now. You get updates as things happen. This helps you plan better and fix problems fast. You can also check the temperature and other details.

What training do staff need?

Staff need to learn how to use equipment and follow safety rules. You should teach them how to check containers and follow steps. Good training stops accidents and keeps work going well.

Related Blogs

-

You use a Container Rotating Spreader to lift sealed bulk containers, rotate them to the desired angle, and unload materials efficiently with minimal spillage. After unloading, you re-seal the containers for transport.Common benefits include:Improved efficiency and cost-effectivenessZero loss materi

You use a Container Rotating Spreader to lift sealed bulk containers, rotate them to the desired angle, and unload materials efficiently with minimal spillage. After unloading, you re-seal the containers for transport.Common benefits include:Improved efficiency and cost-effectivenessZero loss materi