When you choose equipment for your warehouse or yard, you often compare a reach stacker forklift and a standard forklift. Each type fits different tasks.

A reach stacker forklift works best indoors. You can pick pallets from high shelves and move through narrow aisles with ease.

A standard forklift, or counterbalance forklift, handles outdoor work. You use it in larger spaces for general material handling and easy maneuvering.

Your choice depends on your space, the height you need to reach, and the kind of loads you move.

Forklift Types Overview

Reach Stacker Forklift

You use a reach stacker forklift when you need to move and stack heavy containers in ports or large yards. This machine stands out for its flexibility. You can access containers in multiple rows without shifting others. High handling speed helps you boost productivity. Some models stack containers up to six tiers high. You can switch attachments for different cargo types, making it versatile. However, you should know that reach stackers require a higher initial investment and complex maintenance.

Tip: Modern reach stacker forklifts, like the CLARK reach truck, offer advanced controls for precise movement in narrow aisles. You get features such as simultaneous lift and travel, ergonomic cabs, and safety enhancements.

Here are some common types of reach trucks you may encounter:

Walkie reach stacker: Maneuvers easily in tight spaces and high racks.

Walkie straddle stacker: Delivers stable performance for general warehousing.

Counter-balanced stacker: Handles obstacles with stability and versatility.

Standard Forklift

You rely on a standard forklift for everyday material handling. This type includes industrial forklifts, counterbalance forklifts, and rough terrain forklifts. You use them to transport heavy materials on stable surfaces or move loads across flat areas. Their balanced design lets you maneuver easily. You find them in warehouses, manufacturing plants, and outdoor sites.

Forklift Type | Typical Tasks | Unique Features |

|---|---|---|

Industrial Forklift | Move large, heavy materials on stable surfaces | High lifting capacity, robust frames |

Counterbalance Forklift | Load/unload materials across flat surfaces | Balanced design, versatile handling |

Rough Terrain Forklift | Move heavy loads over uneven terrain | Rugged tires, high ground clearance |

Pallet Jack | Shift pallets and small items over short distances | Compact, manual or electric models |

Container Forklift

You choose a container forklift when you need to handle intermodal cargo containers. This machine is designed for ports and terminals. You can stack containers in multiple rows, which saves yard space. The container forklift excels at lifting heavy loads and stacking them high. You find it most useful in shipping yards and logistics hubs.

Container forklifts (reach stackers) specialize in moving heavy containers in ports and terminals.

Traditional forklifts work best for general material handling in warehouses and factories.

Feature | Container Forklifts (Reach Stackers) | Traditional Forklifts |

|---|---|---|

Primary Use | Lifting and moving materials | |

Stacking Capability | Stack containers in multiple rows | Ground-level use |

Design Purpose | Specialized for ports and terminals | Versatile for various settings |

Note: You find container forklifts most effective for stacking and organizing containers in busy logistics environments. If you need to move pallets or smaller items, you should consider other types of reach trucks.

Forklift Class | Fuel Type | Use Description |

|---|---|---|

Class I | Battery | Indoor environments, like warehouses |

Class II | Battery | Shifting stock via confined or constricted areas |

Class III | Battery | Deploying delivery vans quickly across small distances |

Class IV | Diesel or gasoline | Low-clearance scenarios |

Class V | Diesel or gasoline | Rough surfaces both indoors and outdoors |

Class VI | Gas, Diesel, or Batteries | Towing or hauling cargo |

Class VII | Diesel or gasoline | Construction sites; uneven terrain; high altitudes |

You should explore the types of reach trucks available for your specific needs. Each type offers unique advantages for stacking, maneuvering, and handling different loads.

Key Differences

Lifting Capacity

When you compare a reach stacker to a standard forklift, you notice differences in lifting capacity. A reach stacker often handles heavier payloads, making it a high capacity forklift for demanding jobs. Standard warehouse forklifts usually lift between 3,000 and 5,000 pounds. Industrial forklifts can manage 10,000 to 20,000 pounds. A reach stacker typically exceeds these ranges, giving you impressive stacking capacity for large loads. You use a forklift container handler when you need to move heavy containers in logistics yards. This type of forklift offers key advantages for stacking and transporting bulky items.

Forklift Type | Lifting Capacity Range |

|---|---|

Standard Warehouse Forklifts | 3,000 – 5,000 lbs |

Industrial Forklifts | 10,000 – 20,000 lbs |

Reach Stackers | Generally higher than industrial forklifts |

If you need to lift very heavy payloads, a reach stacker gives you the power and stability you need. You should consider reach truck training to operate these machines safely.

Reach and Height

Reach stackers stand out for their ability to lift loads to greater heights. You can stack containers up to six tiers high, which is essential for logistics operations. The maximum lift height for a reach stacker forklift container handler exceeds 330 inches. Standard forklifts reach around 240 inches. This difference lets you maximize vertical space in indoor warehouse applications. Warehouse reach trucks also extend forks deep into shelving, making them ideal for high stacking and retrieval tasks.

Forklift Type | Maximum Lift Height |

|---|---|

Reach Stacker Forklifts | Exceeds 330 inches |

Standard Forklifts | Around 240 inches |

You gain advantages in storage efficiency when you use a reach stacker for high-rack systems.

Maneuverability

You experience exceptional maneuverability with a reach stacker. Its compact design and two outer legs distribute weight, allowing you to navigate narrow aisles and tight spaces. This feature makes reach stackers perfect for indoor warehouse applications. Standard forklifts offer versatility but may struggle in confined areas. The distinctive features of reach stackers include their ability to turn sharply and move quickly, giving you high handling speed in busy environments.

Metric | Reach Stacker Forklifts | Standard Forklifts |

|---|---|---|

Maneuverability | Excellent in narrow aisles | Limited in tight spaces |

Design | Compact for tight spaces | Larger, more robust |

Reach stackers excel in environments where space is limited. You should learn how to operate a reach truck to take full advantage of its maneuverability.

Operating Environments

You use a reach stacker in indoor warehouse applications, especially in logistics centers with high racks and narrow aisles. This forklift container handler is not suitable for outdoor work because it has minimal undercarriage clearance. Standard forklifts work well in various environments, including outdoor sites and mixed-use areas. You can operate a traditional forklift in both wide and narrow aisles, making it a flexible choice for many types of jobs.

Reach stackers: Best for narrow aisles and high-rack storage systems.

Standard forklifts: Suitable for indoor and outdoor environments.

Reach trucks: Not recommended for outdoor use due to low clearance.

Electric reach stackers produce zero emissions, improving air quality and supporting sustainability goals. Standard internal combustion forklifts emit gases, which is a disadvantage in enclosed spaces.

Load Handling

You achieve efficient load handling with a reach stacker forklift container handler. Its design allows you to extend forks deep into shelving, making it ideal for placing and retrieving pallets in tight spaces. The stabilizing legs provide exceptional stability, letting you lift heavy loads high without risk. Standard forklifts handle general cargo well but may struggle with bulky or oddly shaped loads. The key advantages of reach stackers include their ability to handle diverse payloads and maximize stacking speed.

Feature | Reach Stacker Forklifts | Standard Forklifts |

|---|---|---|

Maneuverability | Excellent in narrow aisles | Limited in tight spaces |

Load Capacity | High stacking capability | Versatile but less specialized |

Cargo Suitability | Ideal for bulky or oddly shaped loads | General use, may struggle with specific loads |

Fork Extension | Can extend forks deep into shelving | Fixed forks, less reach |

Reach stackers: Designed for high stacking and deep reach into shelving.

Ideal for handling bulky or oddly shaped loads in narrow aisles.

Enhanced leverage from stabilizing legs allows for lifting heavy loads high without compromising stability.

You benefit from advanced features like ergonomic controls and automated systems, which reduce operator fatigue and improve safety. Reach stackers offer high handling speed and efficiency, making them a top choice for logistics operations.

Types of Reach Trucks

Indoor Use

You find many types of reach trucks designed for indoor warehouse operations. Each type offers unique features that help you work efficiently in tight spaces. Reach stacker models stand out for their ability to handle heavy loads and reach high shelves. You use warehouse reach trucks when you need to maximize storage in narrow aisles. These machines let you stack pallets vertically, which saves valuable floor space.

Here is a table showing common types of reach trucks and their primary uses:

Type of Reach Truck | Primary Use |

|---|---|

Moving Mast Reach Trucks | Flexibility and maneuverability in tight spaces, perfect for narrow aisles. |

7500 Universal Stance Reach Truck | Balanced performance and agility in narrow aisles. |

7500 Dockstance Reach Forklift | Handling goods in dock areas with better visibility and comfort. |

7000 Series Deep-Reach Forklift Truck | High storage density and lift heights for deep-reach applications. |

7200 Reach-Fork Truck | Reliable for various lifting tasks, ensuring safety and productivity. |

7530 High Capacity Reach Truck | Handles heavy loads, ideal for high-capacity needs. |

You gain key advantages when you use a reach stacker indoors. These machines help you optimize space by stacking high and operating in narrow aisles. Precision handling lets you position pallets accurately, which reduces the risk of product damage. You also benefit from improved safety and efficiency.

Tip: Reach stackers and other warehouse reach trucks are built for narrow aisle operation. You can move quickly and safely, even in crowded storage areas.

Operator Position

Your position as an operator plays a big role in safety and efficiency. When you drive a reach stacker, you should keep the forklift forks 4 to 6 inches above the ground and tilt them slightly back. This position helps you secure the load and avoid floor obstacles. Proper fork positioning keeps the load stable and reduces the chance of accidents.

You maintain balance and control by following these guidelines.

You minimize the risk of tipping or dropping loads.

You improve your overall safety during daily operations.

If you want to learn how to operate a reach truck, you should consider reach truck training. Training teaches you the best practices for safe operation and helps you get the most from your equipment. You will also learn about the features that make reach stackers and other reach trucks effective in warehouse settings.

Choosing the Right Forklift

Best Scenarios for Reach Stackers

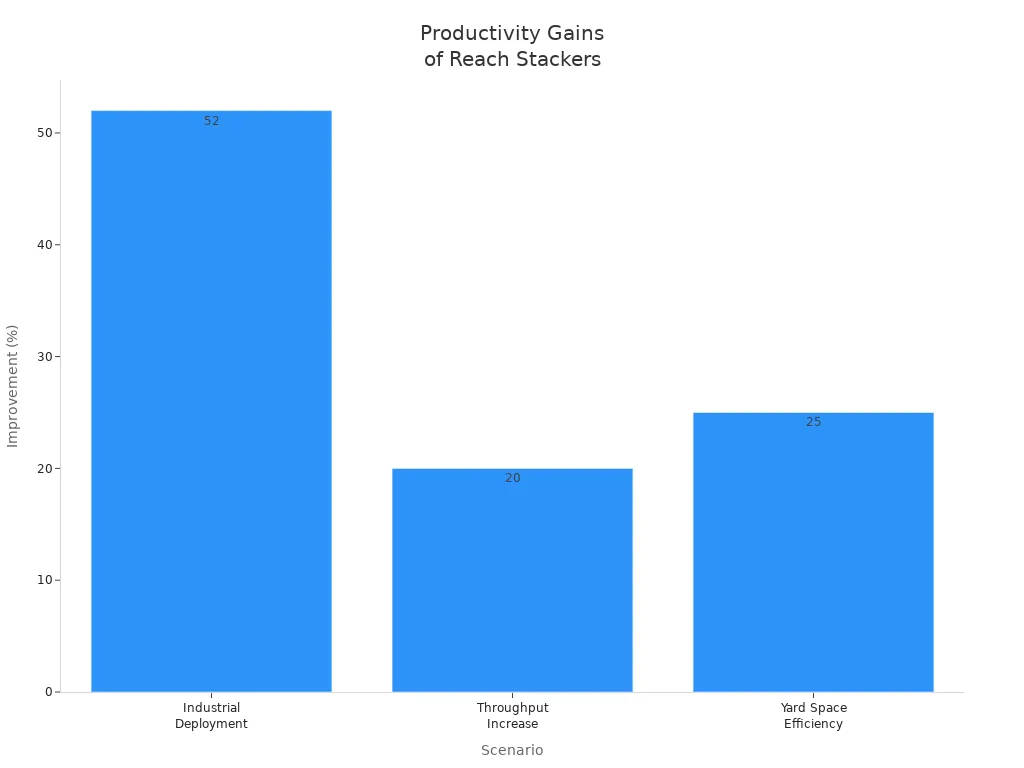

You should choose a reach stacker when you need to move heavy loads quickly and stack them high. This type of forklift works best in logistics yards, ports, and large warehouses. You gain advantages in environments where you must optimize yard space and increase throughput. Reach stackers handle containers and bulky items with ease. Their distinctive features include automated load monitoring and advanced safety systems. You can boost productivity by up to 20% with lifting cycle optimization. Electric and hydraulic models help you reduce fuel consumption and maintenance needs.

Scenario | Benefit of Reach Stackers |

|---|---|

Container stacking in ports | High stacking capability, space efficiency |

Industrial facilities | 52% global deployment, high productivity |

Large logistics yards | Yard space efficiency up to 30% |

High-rack warehouse storage | Maximum lift height, deep reach |

You should also consider the operational environment. Reach stackers perform best indoors or on smooth surfaces. You need trained operators to manage elevated loads safely. If you want to explore advanced reach stacker models, you can visit Tona-Tec Reach Stackers for more information.

Tip: Reach stackers offer speed and efficiency for high-volume container handling. You can improve safety and reduce operational errors with automated features.

Best Scenarios for Standard Forklifts

You should select a traditional forklift for general material handling in warehouses, factories, and outdoor sites. Standard forklifts excel at moving pallets, loading and unloading goods, and working with pallet rack storage systems. You find these types effective in storage systems with heights less than 24.6 feet. Their versatility allows you to handle many tasks in logistics and warehousing environments.

Counterbalanced forklifts work well for loading and unloading pallets.

You can move goods within warehouses and across flat surfaces.

Standard forklifts adapt to both indoor and outdoor use.

You benefit from simple controls and reliable performance.

You should assess your business needs before choosing a forklift. Consider the average weight and dimensions of your loads, the maximum height you need to reach, and the environment where you will operate the equipment.

Note: Standard forklifts provide flexibility for various tasks. You can use them in mixed-use areas and rough terrain with specialized models.

Cost and Maintenance

You need to evaluate cost and maintenance before making your decision. Maintenance and operational costs vary between forklift types. Diesel or gasoline forklifts may incur higher costs over time. Electric reach stackers help you lower fuel consumption and reduce maintenance needs. You should factor in operator training, as reach stackers require additional skills for safe operation.

Forklift Type | Initial Cost | Maintenance Cost | Fuel/Energy Cost | Operator Training |

|---|---|---|---|---|

Reach Stackers | High | Moderate | Low (electric) | Advanced |

Standard Forklifts | Moderate | High (diesel/gas) | High (diesel/gas) | Basic |

You should also consider the frequency of use. If you operate equipment daily in demanding environments, investing in a reach stacker may offer long-term savings and efficiency. For occasional use or general tasks, a standard forklift provides a cost-effective solution.

Tip: Electric reach stackers support sustainability goals and help you improve air quality in indoor environments.

When choosing between reach stackers and standard forklifts, you should consider these factors:

Load capacity

Lift height

Operational environment

Frequency of use

Safety features

Maintenance and operational costs

Required operator training

You can make the right choice by matching your business needs to the distinctive features of each forklift type.

Comparison Table

Quick Reference

You can use the following table to compare reach stacker forklifts and standard forklifts. This quick reference helps you choose the right equipment for your needs.

Feature | Reach Stacker Forklifts | Standard Forklifts |

|---|---|---|

Design | Uses a pantograph to extend forks forward | Counterbalanced with a rear weight |

Center of Gravity | Closer to forks, no counterweight | Heavy weight at the rear for stability |

Maneuverability | Requires less aisle space (about 8 feet) | Needs more aisle space (10-12 feet) |

Lifting Capacity | Limited to about 4,500 lbs | Can lift over 100,000 lbs |

Best Use | Indoor, narrow aisles, tall racking | Versatile, used indoors and outdoors |

Fuel Options | Battery-powered only | Multiple fuel types available |

Operator Position | Operator stands while operating | Operator sits in a cabin |

Stability | Mast stabilizes the forklift | Dense mass at the rear counterbalances load |

Tip: Reach stacker forklifts work best in narrow aisles and high storage racks. You can recover goods stored high with ease. Standard forklifts are commonly used in warehouses and for extremely heavy loads.

Reach stacker forklifts offer incredible maneuverability in tight spaces.

Standard forklifts provide stable operation and handle heavy loads efficiently.

You should review this table before making your final decision. The right forklift improves safety, productivity, and storage efficiency in your facility.

You see clear differences when you compare a reach stacker forklift to a standard forklift. Reach stackers work best in narrow aisles and high racking, letting you maximize storage density. Standard forklifts handle a wide range of tasks indoors and outdoors. Operators using reach stackers lift with the load, while standard forklift operators work at ground level. If you need to stack high and save space, choose a reach stacker. For general material handling, a standard forklift gives you more flexibility.

Feature | Reach Stacker Forklift | Standard Forklift |

|---|---|---|

Ideal Use | Narrow aisles and high racking | Versatile for indoor/outdoor use |

Operator Functionality | Operator platform lifts with the load | Ground-level loading/unloading |

Design | Compact, designed for high stacking | Bulkier, requires wider operating space |

Reach stackers excel in warehouses with vertical storage needs.

Standard forklifts adapt to many environments and tasks.

Tip: Match your choice to your space, load type, and stacking needs for the best results.

FAQ

What is the main difference between a reach stacker forklift and a standard forklift?

You use a reach stacker forklift to move and stack a container in high racks or tight spaces. A standard forklift works best for general material handling. You often see reach stackers in container yards and logistics operations where you need to handle a container quickly.

Can I use a reach stacker forklift outdoors?

You should use a reach stacker forklift mainly indoors or on smooth surfaces. Outdoor use is possible, but you may face challenges with uneven ground. For moving a container outdoors, you might prefer a rough terrain forklift or a specialized container handler.

How many containers can a reach stacker forklift stack?

You can stack up to six containers high with a reach stacker forklift. This ability helps you save space in a container yard. You often see this stacking method in logistics operations that require efficient container management and high-density storage.

What type of forklift is best for moving containers in a port?

You should choose a reach stacker forklift or a container handler for port work. These machines let you move a container quickly and stack it efficiently. You improve productivity in logistics operations by using equipment designed for heavy container handling.

Where can I find reliable reach stacker forklifts for container handling?

You can visit Tona-Tec Reach Stackers for a range of reach stacker forklifts. These machines help you move and stack a container safely and efficiently in logistics operations or container yards.