You can see how containerized bulk handling changes logistics efficiency every day. The rise of international trade and e-commerce pushes you to find faster ways to move goods. Solutions like Efficient Containerized Bulk Handling, High-Speed Containerized Bulk Handling, and Stainless Steel Containerized Bulk Handling help you load and unload bulk materials with speed and safety. Products such as TR350R Containerized Bulk Handling and TCZ400R Containerized Bulk Handling show how manufacturers use automation, IoT, and eco-friendly designs to make your work easier and more reliable. These advances mean you can handle more cargo, reduce costs, and keep your operations running smoothly.

Key Takeaways

Containerized bulk handling speeds up loading and unloading while protecting cargo in sealed containers.

Using automation and tracking technology improves safety, reduces errors, and gives real-time shipment visibility.

This method lowers logistics costs by cutting transport expenses, reducing product loss, and saving labor.

Choosing the right containers and following best loading practices keeps cargo safe and operations efficient.

Overcoming challenges like port congestion and equipment costs is possible with smart planning and training.

What Is Containerized Bulk Handling

Definition and Process

You use containerized bulk handling to move large quantities of goods in sealed, standardized containers. This method helps you protect your cargo, speed up loading and unloading, and keep your supply chain running smoothly. The process follows clear steps that make your logistics more reliable and efficient.

Preparation for a load: You confirm shipping terms, check equipment, make sure everything is clean, and review safety data.

Loading: You load the right amount of product into the container. If you are new to the system, technical support can help you.

Shipment: You organize documents and track your shipment with updates from your service provider.

Delivery and Discharge: You work with the receiver to plan delivery and use technical support to ensure safe unloading.

Empty Return & Recycling: You return empty containers to the right place and manage recycling.

Tip: Following these steps helps you avoid delays and keeps your cargo safe from start to finish.

Key Features

Containerized bulk handling stands out from traditional bulk shipping. You get faster operations, better cargo protection, and more cost savings. The table below shows how containerized bulk handling compares to older methods:

Feature | Traditional Bulk Handling Methods | |

|---|---|---|

Packaging | Uses standardized, sealed containers for protection and security | Unpackaged goods loaded directly |

Loading/Unloading | Containers lifted as single units, faster process | Individual handling, slower and complex |

Cargo Protection | Sealed containers reduce damage and theft | Higher risk of damage and theft |

Cost Efficiency | More cost-effective for regular shipments | More expensive for regular cargo |

Stacking & Storage | Containers can be stacked efficiently | Cargo cannot be stacked |

Security | Lockable containers improve security | Less secure, more risk |

Flexibility | Seamless intermodal transport, standard sizes | Flexible for oversized cargo |

You benefit from recent technology, too. Automation, real-time tracking, and smart analytics help you move containers faster and safer. These tools give you better control and visibility over your shipments. The invention of standardized containers in the 1950s changed the way you handle bulk cargo. Now, you can move goods between ships, trains, and trucks without extra handling, saving time and money.

Benefits for Logistics

Efficiency Gains

You can achieve remarkable efficiency gains when you use containerized bulk handling systems. Modern ports use automated loading and unloading equipment. This technology speeds up the movement of goods and reduces manual labor. You benefit from standardized containers, which allow cranes and trucks to handle cargo quickly and safely.

A mining logistics project in Chile showed that containerized bulk handling can reach shiploading rates of 1,500 tonnes per hour. This matches the speed of traditional bulk methods but adds the advantage of sealed cargo, which reduces contamination and environmental impact.

You can also see measurable improvements in your operations:

30% reduction in transit times and 20% decrease in logistical costs with IoT-enabled container tracking.

15% reduction in empty container movements and lower carbon emissions using AI-driven loading optimization.

25% reduction in lead times and 20% improvement in on-time delivery rates in retail logistics.

30% reduction in product spoilage for temperature-sensitive goods in healthcare.

20% reduction in production timelines and improved supply chain coordination in the automotive industry.

You can use data-driven truck appointment systems to optimize scheduling. This reduces truck waiting times and speeds up bulk cargo handling. Dynamic yard crane scheduling and efficient truck flow management also help you avoid congestion at container terminals. These improvements make your logistics operations faster and more reliable.

Safety and Security

You improve safety and security when you choose containerized bulk handling. International codes such as the IMO Code of Safe Practice for Cargo Stowage and Securing help you follow strict safety standards. You use ship-specific Cargo Securing Manuals to ensure proper loading and securing for each vessel and cargo type. These manuals include loading procedures, securing calculations, equipment specifications, and emergency protocols.

You can rely on advanced safety systems like GPS tracking and container condition sensors. These tools give you real-time monitoring and automated alerts. You can act quickly if a problem arises, which helps prevent accidents. Specialized handling techniques and stowage methods keep cargo stable and reduce the risk of damage.

Cargo security inspection services add another layer of protection. You use X-ray scanning, physical inspections, and documentation checks to prevent smuggling and ensure compliance. Continuous training and certification for your staff keep safety standards high. These measures protect your cargo, your people, and the environment.

You also reduce product loss and contamination. Sealed containers keep bulk materials safe from dust and external contaminants. Container liners form a barrier against moisture and help maximize space. Equipment like the RAM Revolver ensures complete unloading without product loss. Optional dust suppression systems further reduce contamination risks.

Cost Reduction

You can lower your logistics costs significantly by using containerized bulk handling. Intermodal transportation, which combines rail, ship, and truck, offers major savings for long-distance freight. For example, using rail instead of trucks can cut transportation costs by 20-30% for trips over 500 miles. Intermodal rail-truck combinations save between $0.05 and $0.15 per ton-mile compared to trucking alone. The Federal Highway Administration reports that intermodal corridors can reduce transportation costs by up to 15%.

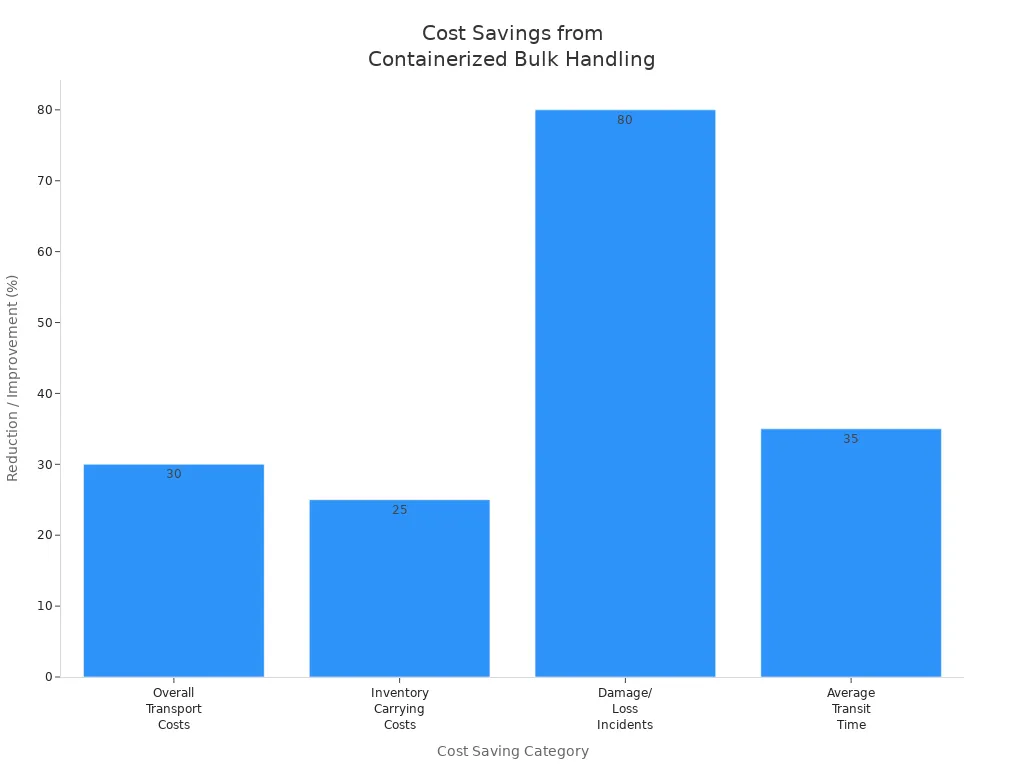

Here is a summary of documented cost savings:

Cost Saving Category | Documented Reduction/Improvement | Description/Impact |

|---|---|---|

Overall Transport Costs | Up to 30% | Containerized bulk handling reduces transport costs compared to break-bulk methods. |

Inventory Carrying Costs | 25% | More efficient inventory management lowers carrying costs. |

Damage/Loss Incidents | 80% reduction | Containerization significantly reduces product damage and loss during transit. |

Average Transit Time | ~35% reduction | Faster handling and streamlined processes reduce transit time. |

You can also save money by consolidating shipments into full container loads. This gives you economies of scale and lowers your per-unit transportation costs. Intermodal transport helps you optimize fuel efficiency and reduce warehousing needs. You can negotiate better freight rates by leveraging your shipping volume and flexibility.

Containerized bulk handling reduces packaging, labor, cleaning, and maintenance costs. Faster loading and unloading mean shorter port stays and better supply chain efficiency. These savings make containerized bulk handling a smart choice for your logistics operations.

Core Components and Technologies

Bulk Containers

You rely on different types of bulk containers to move materials safely and efficiently. Each type serves a unique purpose in containerized bulk handling. Some containers are rigid and reusable, while others are flexible or collapsible for easy storage. The table below shows the most common types and their typical capacities:

Container Type | Description | Typical Capacity Range |

|---|---|---|

Rigid Intermediate Bulk Container (IBC) | Reusable, stackable containers made from metal, plastic, or composite materials. Used for liquids and solids. | 500 to 1,250 liters (common sizes: 1,040 L, 1,250 L) |

Collapsible IBC | Similar to rigid IBCs but collapsible for easier storage and transport when empty. | 500 to 1,250 liters |

Flexible IBC (Big Bags) | Made from woven polyethylene or polypropylene, designed for dry, flowable products like sand or fertilizer. | 285 to 2,830 liters |

You also use bulk containers like bulktainers for minerals, open-top containers for heavy equipment, and tank containers for liquids and gases. Stainless Steel Containerized Bulk Handling options give you extra durability and hygiene, especially for food and chemicals.

Loading and Unloading Systems

You need reliable systems to load and unload bulk materials quickly. Modern solutions include container tilting, automated revolvers, and custom liners. For example, TR350R Containerized Bulk Handling and TCZ400R Containerized Bulk Handling systems help you unload dry bulk goods like cement or grain with less material loss. These systems use heavy-duty construction and precise tilting to empty containers fast and safely. Some systems even add dust suppression and energy-saving features, making your operation cleaner and more efficient.

Innovative companies now offer equipment that lets you transfer materials directly from containers to silos or trucks. Patented tippler systems can rotate containers 360 degrees, unloading them in under a minute. This reduces labor, prevents spills, and keeps your cargo safe.

Automation and Tracking

You can boost your efficiency with automation and smart tracking. Automated cranes, robotic loaders, and smart sensors speed up loading and unloading. These tools lower labor costs and reduce mistakes. You can also use GPS and RFID tags to track containers in real time. Automated systems help you manage yard space, monitor container conditions, and keep your cargo secure.

Manufacturers play a key role in developing these advanced systems. Choosing the right equipment for your needs ensures you get the best results. Automation and tracking make containerized bulk handling safer, faster, and more reliable for your business.

Implementation Strategies

Assessing Needs

You should start by understanding your logistics requirements before adopting containerized bulk handling. Begin by identifying the type of product you want to transport. Hazardous liquids need ISO Tanks, while non-hazardous liquids can use Flexitanks. Always check the Material Specification Data Sheets to confirm compatibility. Next, look at your shipment volume. If you move large amounts, such as 20,000 liters per month, containerized bulk handling becomes cost-effective. Check if your facilities can support loading, unloading, and storage. If you lack the right infrastructure, you may need to consider other packaging methods. Think about how often you ship. Frequent shipments make containerized bulk handling more practical. Review your supply chain to spot any challenges before you begin.

Integration Steps

You can follow a clear process to add containerized bulk handling to your operations:

Prepare for loading by confirming shipping terms, checking equipment, and sharing safety data.

Load the correct amount of product and arrange technical support if you are new to the system.

Monitor your shipment with proper documentation and real-time updates.

Coordinate with the receiver for delivery and use technical support for safe unloading.

Return empty containers and manage recycling.

When choosing between efficient and high-speed solutions, consider your product type, shipment volume, and how often you ship. Select a provider with strong technical support, regulatory compliance, and digital management systems.

Tip: Providers who own and manufacture their equipment often offer better support and innovation.

Training and Change Management

You need to train your staff to operate new equipment safely. Focus on safe machinery operation, proper container handling, and accident prevention. Make sure your team understands industry regulations and maintenance duties. Regular training and refresher courses help keep everyone updated. Interactive courses with videos and discussions work well for new staff. Well-trained operators help you reduce risks and improve efficiency. Change management also matters. Address any concerns about new technology by showing how containerized bulk handling fits your specific needs and improves your logistics.

Best Practices

Container Selection

You need to choose the right container for your bulk materials. The right choice keeps your cargo safe and your operations efficient. When you select a container, consider these important factors:

Material Compatibility: Match the container to your product. For powders, use sift-proof seams. For food, pick food-grade liners. For hazardous goods, look for anti-static features.

Load Capacity: Check the Safe Working Load (SWL) and stacking needs. Make sure the container can handle the weight and volume.

Safety Measures: Use containers from reputable manufacturers with certifications like ISO or UN. Regular inspections and maintenance keep your containers reliable.

Supplier Expertise: Work with suppliers who know your industry. They can help you find the best Containerized Bulk Handling solution.

Factor | Description |

|---|---|

Material Characteristics | Size, shape, weight, abrasiveness, and moisture content affect your container choice. |

Environmental Factors | Temperature, dust, and moisture can impact container durability and safety. |

Product Integrity | Choose containers that protect your product from contamination and damage. |

Tip: Stainless Steel Containerized Bulk Handling offers extra durability and hygiene for sensitive products.

Loading Optimization

You can improve your loading process by following a few key steps:

Distribute weight evenly inside the container to keep it stable.

Stack pallets properly. Use strong pallets, place heavy items at the bottom, and avoid overhangs.

Control stack height and fill empty spaces to prevent cargo from shifting.

Use column stacking to save space and make loading safer.

Always check the total weight to avoid overloading.

Use equipment designed for your product, like TR350R Containerized Bulk Handling or TCZ400R Containerized Bulk Handling systems.

You should also inspect containers for damage. Look for fraying, cracks, or seam failures. Regular testing, like lift and drop tests, helps prevent accidents and product loss.

Note: Automated systems and smart sensors in Efficient Containerized Bulk Handling and High-Speed Containerized Bulk Handling can make your loading faster and safer.

Real-World Examples

You can see the benefits of best practices in action at major logistics sites:

Location / Facility | Technology / System Used | Key Benefits and Outcomes |

|---|---|---|

CODELCO, Chile | RAM Spreaders' Revolver® system | Clean, efficient copper handling with sealed containers, reducing dust and contamination. |

Riga Universal Terminal, Latvia | RAM Revolver® | Saved 50% in costs and resources, handled large dry bulk ships, and combined bulk and container handling at one pier. |

DP World Fraser Surrey, Canada | Rotating containers | Reduced dust loss and product damage, improved environmental safety, and increased competitiveness. |

You can apply these best practices to your own operations for safer, faster, and more reliable Containerized Bulk Handling.

Challenges and Solutions

Common Obstacles

When you start using Containerized Bulk Handling, you may face several challenges. Many companies report similar issues during adoption:

Inefficient cargo handling can cause errors, damage, and slowdowns in your supply chain.

Port congestion often results from limited capacity and busy global trade routes. This can lead to delays and higher costs.

Container imbalances happen when some locations have too many containers while others have too few. You may need to reposition empty containers, which increases expenses.

High initial investment costs for equipment like Efficient Containerized Bulk Handling systems can be difficult, especially for smaller businesses.

Infrastructure at some ports may not support new technology. You might find there is not enough space for cranes or the power supply is too weak.

Compatibility issues with advanced equipment, such as TR350R Containerized Bulk Handling or TCZ400R Containerized Bulk Handling, can slow down your progress.

Specialized machinery often requires skilled workers. Training your team takes time and resources.

The need to keep up with new technology and environmental rules adds pressure to your operations.

These obstacles can make your logistics more complex and increase your costs.

Overcoming Barriers

You can overcome these barriers by using proven strategies. Many logistics professionals use specialized equipment like transloading containers, gantry cranes, and reach stackers to improve efficiency and safety. Portable loading ramps help you work around dock shortages and keep your operations moving.

You can also develop cargo loading plans that focus on proper weight distribution. This helps you meet different regional weight limits and avoid fines. Real-time container tracking technology gives you better visibility in your yard and helps you manage your fleet.

Driver-assist load systems can help you deal with labor shortages. Palletizing your goods makes handling and storage easier, and it reduces your reliance on container availability. Transloading cargo allows you to redistribute loads, comply with weight limits, and avoid costly permits.

By using these solutions, you can reduce port congestion, speed up turnaround times, and keep your High-Speed Containerized Bulk Handling operations running smoothly. When you choose the right tools and invest in training, you set your business up for success in modern logistics.

You can see how Containerized Bulk Handling changes the way you move goods. Solutions like TR350R, TCZ400R, and Stainless Steel Containerized Bulk Handling help you work faster and safer. You can lower your costs and protect your cargo. If you want to keep your business strong, explore these options. New technology will keep making bulk logistics better in the future.

FAQ

What is Containerized Bulk Handling?

You use Containerized Bulk Handling to move large amounts of goods in sealed containers. This method keeps your cargo safe and speeds up loading and unloading. You can use it for grains, minerals, chemicals, and more.

How do TR350R and TCZ400R Containerized Bulk Handling systems help you?

TR350R Containerized Bulk Handling and TCZ400R Containerized Bulk Handling systems let you load and unload bulk materials quickly. You save time and reduce product loss. These systems use strong designs and smart technology.

Why should you choose Stainless Steel Containerized Bulk Handling?

Stainless steel containers give you extra strength and hygiene. You can use them for food, chemicals, or any product that needs a clean surface. They last longer and resist rust.

What are the main benefits of Efficient and High-Speed Containerized Bulk Handling?

Benefit | Efficient System | High-Speed System |

|---|---|---|

Speed | Steady, reliable flow | Fast loading and unloading |

Cost Savings | Lower labor and transport cost | Less downtime, higher throughput |

Safety | Fewer accidents | Less product loss |

How do you track your containers during shipping?

You use GPS and RFID tags to track your containers. These tools show you where your cargo is at any time. You get alerts if there is a problem. This helps you keep your shipments safe and on schedule.